When choosing stainless steel materials in industrial, marine, or structural engineering projects, duplex stainless steel and 316 stainless steel are the two most commonly compared materials. They all have excellent corrosion resistance, but there are significant differences in strength, cost, and performance in harsh environments.

This article will provide a detailed analysis of the differences between duplex stainless steel and 316 stainless steel to help you choose the appropriate material.

Duplex vs 316 stainless steel Definition and Characteristics

Definition and Characteristics of 316 stainless steel

316 stainless steel belongs to austenitic stainless steel and contains molybdenum (Mo) element, so its corrosion resistance in chlorine containing environments is better than that of 304 stainless steel.

Main Features

Excellent corrosion resistance performance

Good formability and weldability

Excellent resistance to pitting and crevice corrosion

Basically non-magnetic in annealed state

Wide market supply and easy processing

Definition and Characteristics of duplex stainless steel

Duplex Stainless Steel has a duplex structure consisting of approximately 50% austenite and 50% ferrite, which combines high strength and excellent corrosion resistance.

Main Features

The strength is about twice that of 316 stainless steel

Excellent resistance to stress corrosion cracking (SCC)

Excellent performance in high chloride ion environments

Low nickel content, relatively less price fluctuation

Good anti fatigue performance

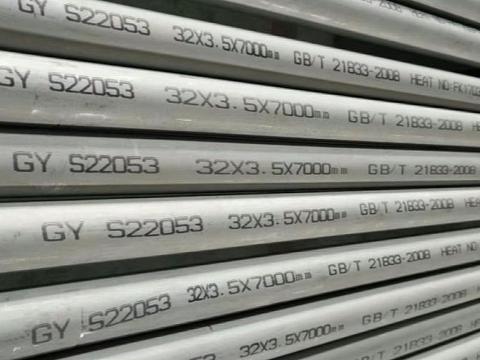

S22053 duplex stainless steel

316 stainless steel pipe

Comparison between duplex vs 316 stainless steel

Chemical Composition

| Element | 316 stainless steel | Duplex stainless steel |

| Chromium (Cr) | 16-18% | 21–23% |

| Nickel (Ni) | 10–14% | 4.5–6.5% |

| Molybdenum (Mo) | 2–3% | 2.5–3.5% |

| Nitrogen (N) | – | 0.1–0.3% |

Performance comparison

| Performance | 316 Stainless Steel | Duplex Stainless Steel |

| Metallographic structure | Austenite | Austenite+Ferrite |

| Yield strength | ~200-300 MPa | ~450-550 MPa |

| Tensile strength | ~500-700 MPa | ~700-900 MPa |

| Corrosion resistance | Excellent | Better (especially resistant to chloride ions) |

| Stress Corrosion Cracking Resistance | Moderate | Extremely Strong |

| Welding performance | Very good | Good (requires control of heat input) |

| Cost | Low initial cost | High unit price but can reduce material thickness |

| Is there magnetism | None (annealed state) | Slightly magnetic |

Differences between processing and welding

| Processing factors | 316 stainless steel | Duplex stainless steel |

| Cold forming | Easier | Requires greater forming force |

| Welding | High fault tolerance | Need to control heat input |

| Machining | Medium difficulty | Slightly difficult |

316 is more suitable for complex processing and large-scale welding scenarios, while duplex steel has stricter requirements for welding processes.

2205 duplex plate

duplex seamless tube

Purchase suggestions

Suitable for choosing 316 stainless steel:

1 · limited budget

2 · Corrosion environment is relatively mild

3 · Complex molding or welding is required

4 · Conventional equipment in the food or pharmaceutical industry

Suitable for selecting duplex stainless steel:

1 · Seawater or high chlorine environment

2 · Requires high-strength and lightweight design

3 · Worried about stress corrosion cracking

4 · Pursuing long-term durability

Summary

Both of these materials are excellent, but with different focuses:

- 316 stainless steel: strong universality, corrosion resistance, easy processing.

- Duplex phase stainless steel: higher strength, stronger resistance to chlorine corrosion, and longer service life in harsh environments.

If the project involves marine engineering, chemical or high salt environments, duplex stainless steel is usually a more reliable long-term choice; In the general industrial and construction fields, 316 is a classic material with extremely high cost-effectiveness.