Bobina de acero Galvalume

Ancho: 600-1250 mm o personalizable

Espesor: 0,13-3,0 mm

Plating: 60g/m² – 150g/m²

Estilo de diseño: Personalizable

Presentación del producto

Bobina de acero galvanizado is a kind of steel coil with better corrosion resistance after galvanized steel coil. It is composed of 55% aluminum (Al), 43.5% zinc (Zn) and 1.5% silicon (Si) solidified at 600℃ to form a dense quaternary crystal of aluminum, iron, silicon and zinc. This crystal forms a solid barrier on the surface of the steel coil, which can effectively prevent the occurrence of corrosion.

El proceso de producción de bobinas de acero galvanizado adopta principalmente un proceso de recubrimiento fundido continuo, que es similar al proceso de bobinas de acero galvanizado y bobinas de aluminio, pero el tanque de fusión es diferente. La temperatura del tanque de fusión de aluminio es de aproximadamente 700 ℃, mientras que la temperatura del tanque de fusión de zinc es de solo 450 ℃.

Parámetros del producto

| Artículo | Parámetros del producto |

| Nombre | Bobina de acero Galvalume |

| Largo | Según sus necesidades |

| Estándar | AiSi, ASTM, bs, DIN, GB, JIS |

| Grado del material | Dx51D、Dx52D、SGCC、SGHC、SGCH, etc. |

| Técnica | Cold Rolled |

| Peso del rollo | 2-5 toneladas por bobina |

| Certificado | ISO9001, SGS |

| Cantidad mínima de pedido | 10 toneladas |

| Loading Port | Qingdao/Tianjin Puerto |

| Condiciones de pago | Pago por adelantado del 30 % + pago del saldo del 70 % antes del envío T/T, 100 % L/C a la vista |

| Paquete | Paquete de exportación estándar |

| Ciclo de entrega | Entre 5 y 15 días laborables tras el pago, según la cantidad del pedido. |

Vídeo de producción de productos

Características

Resistencia a la corrosión: El acero alu-zinc tiene una resistencia superior a la corrosión y su capacidad anticorrosiva integral es cuatro veces mayor que la del acero galvanizado del mismo espesor. Cuando el zinc se desgasta, el aluminio forma una capa densa de óxido de aluminio para evitar que las sustancias corrosivas sigan corroyendo el interior.

Resistencia al calor: Puede soportar altas temperaturas y es adecuado para entornos con altas temperaturas. Puede soportar temperaturas de más de 300 grados Celsius.

Reflectividad térmica: La reflectividad térmica es muy alta, el doble que la de las láminas de acero galvanizado. La superficie puede reflejar una gran cantidad de calor y luz, lo que ayuda a ahorrar energía y se utiliza a menudo como material de aislamiento térmico.

Rendimiento del procesamiento: Tiene un buen rendimiento de procesamiento y se puede estampar, cortar, soldar y realizar otras operaciones. El revestimiento tiene buena adherencia a la película de pintura y es fácil de rociar.

Eficiencia económica: Con el mismo peso y el mismo espesor de recubrimiento, el área del acero alu-zinc es más de un 3% mayor que la del acero galvanizado porque la densidad del acero galvanizado es menor que la del zinc.

Belleza: La superficie es lisa y decorativa.

Áreas de aplicación

Construcción: Se utiliza para techos, paneles de pared, cielorrasos, etc.

Electrodomésticos: Se utiliza para refrigeradores, lavadoras, aires acondicionados, etc.

Automóviles: Se utiliza para piezas de carrocería, tubos de escape, etc.

Industria: Se utiliza para tanques de almacenamiento, conductos de ventilación, etc.

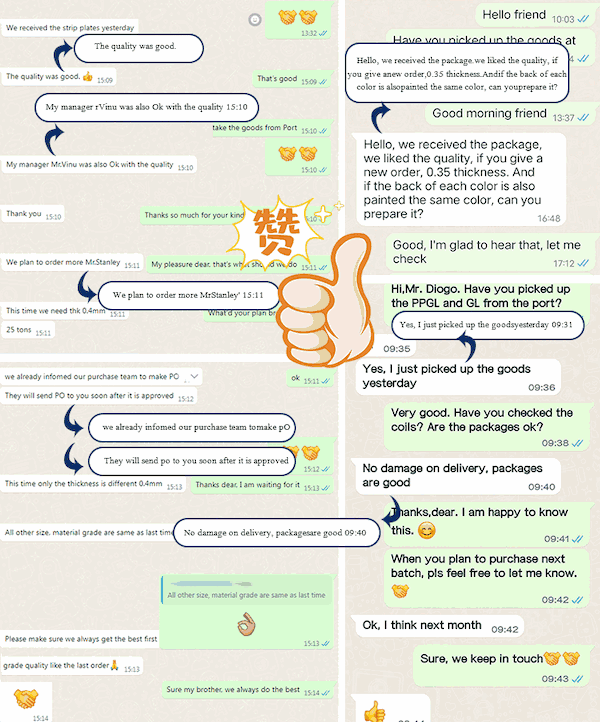

Elogios del cliente

¿Por qué elegirnos?

Empresas con alto ranking comercial en la industria del acero.

Adquisición única de procesamiento de acero personalizado.

Las exportaciones de acero han superado los 200 millones durante cinco años consecutivos.

Customized products can be produced in 5 days.

We have a complete set of testing equipment, such as UV aging chamber, salt spray testing machine, universal testing machine, Rockwell hardness tester, electroplating thickness tester, T-bending testing machine, etc., and have passed IOS, SGS, TUV certification.

Contacto

FábricaCiudad de Binzhou, provincia de Shandong, ChinaArtículo de lista

Compañíadistrito, ciudad de Zhengzhou, provincia, China

WhatsApp: +86 18736065220

E-mail: info04@wanzhisteel.com

Etiquetas populares: Galvalume, bobina de acero, acero galvalume, metal galvalume, fabricantes, proveedores, fábrica, precio, venta, chapa de acero galvalume en bobina