Sandwich Steel Panel

Sandwich Steel Panel Introduction

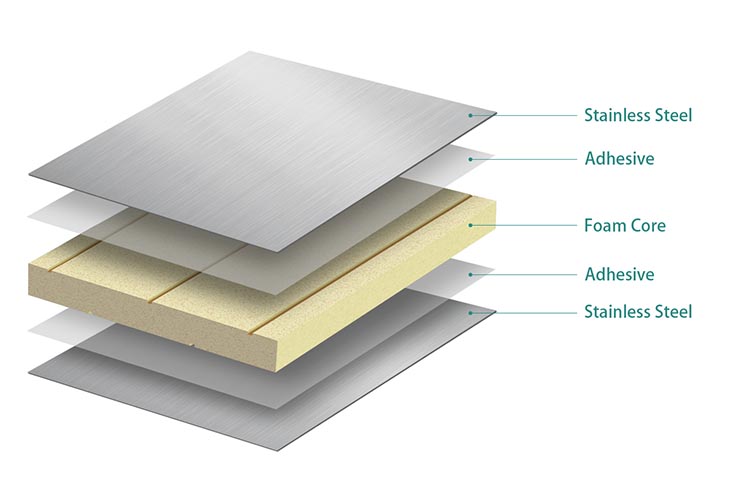

Sandwich steel panel is a composite plate composed of two layers of formed steel plates sandwiched between a layer of thermal insulation material. The face plate of sandwich panels is usually made of high-strength steel plates, while the core material is made of lightweight materials such as polyurethane, rock wool or glass wool, etc. These core materials are not only light in weight, but also has the high strength, good heat insulation performance, fire and moisture-proof, easy installation and so on.

The sandwich steel plate is a common product in the current building, which can not only be a good flame retardant and sound insulation but also environmentally friendly and efficient. Widely used in construction, ships, automobiles and other fields.

Sandwich plate construction

Performance characteristics of Sandwich Steel Panel

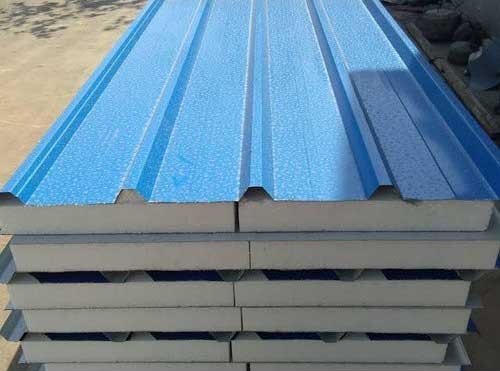

1. Thermal insulation: The fillers of sandwich panels are generally polystyrene, polyurethane, glass wool, and rock wool. These fillers all have good thermal insulation properties and can effectively reduce energy consumption.

2. Fire and moisture resistance: Because the outer layer of the sandwich steel plate is made of galvanized steel, color steel and other steel, it has good waterproof and fire resistance properties; and the internal fillers are also non-flammable and non-absorbent.

3. High strength: The steel plates on both sides of the sandwich panel can effectively protect the quality and shape of the filler, making the sandwich steel plate have high strength and stability.

Sandwich Steel Panel

Sandwich Steel Plate

4. Convenient construction: Sandwich composite panels have the characteristics of light weight, splicing installation, and being cut at will. Therefore, they are easy to install, which can greatly improve construction efficiency, save construction periods, and reduce time costs.

5. Durability: The outer layer of sandwich steel plates is generally stainless steel alloy or color steel. Various studies and extensive use have confirmed that the shelf life of specially treated steel plates is generally more than 10 years; If an anti-corrosion coating can be sprayed every 10 years, the life of the plate can reach more than 35 years.

6. Aesthetic: The sandwich steel plate has clear lines and dozens of colors, which can meet the needs of any style of building to achieve satisfactory results.

Selection of Sandwich Steel Panels

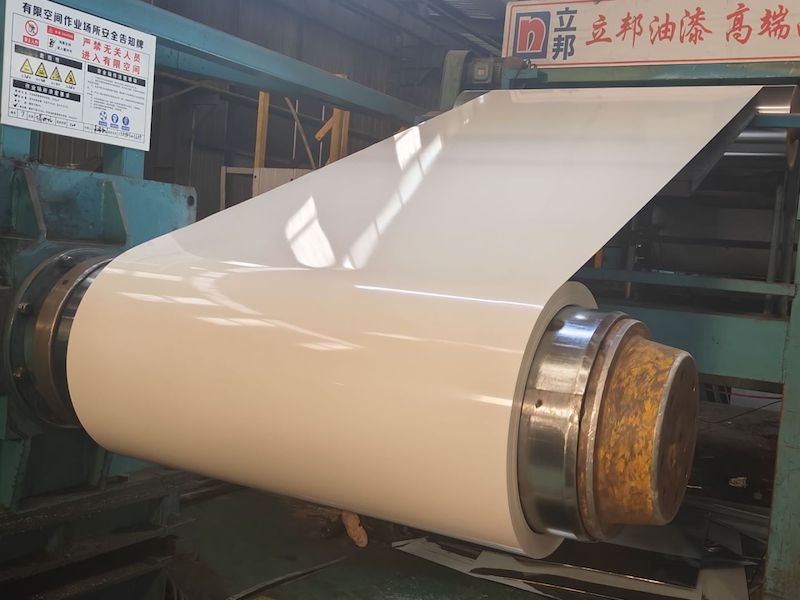

Due to the low investment in sandwich steel plate production, low technological process thresholds, and widespread duplication of investment, the market competition in this industry is fierce. Some companies seek orders by lowering prices and cut corners in the selection of raw materials, resulting in low product quality.

Therefore, when purchasing products, the thickness of the upper and lower steel plates and the density of the intermediate core material should be observed. At the same price, the thicker the metal surface material, the better, and the denser and better the core material. Besides Manufacturers and sellers must also be required to provide quality inspection reports. If there are conditions, you can also find a three-party testing agency to conduct testing.

The Sandwich steel panel with too thin steel plates and too small core material density may cause overturning and collapse accidents during actual use.

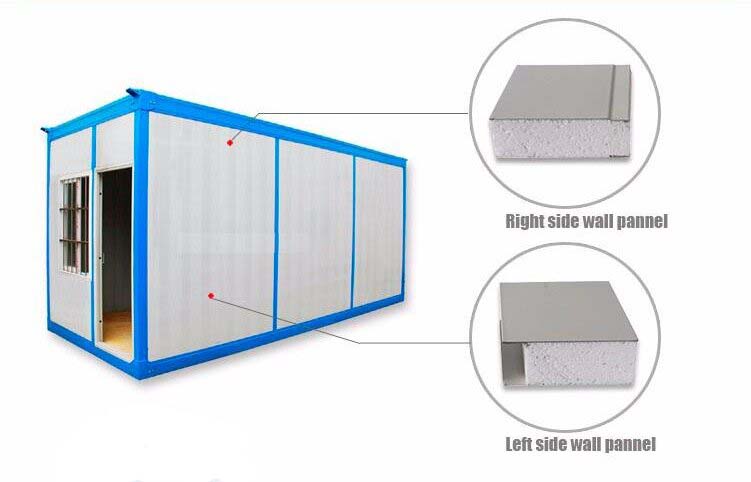

Sandwich Steel Panel Container

Application of Sandwich Steel Panels

The Sandwich steel panels are widely used, especially in the fields of construction and engineering. Sandwich steel panels combined with different core materials and different types of steel can be used for different building needs. Including but not limited to industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activity rooms, building layering, clean workshops and places that require thermal insulation and fire prevention.

Sandwich Steel Roof

Prefabricated Constructions

The sandwich steel panel has a beautiful appearance, bright color, and good overall decoration effect. It integrates load-bearing, thermal insulation, fire prevention and waterproofing, and does not require secondary decoration. Sandwich steel panel is a widely used plate, especially in temporary facilities on construction sites such as offices, warehouses, fences, etc., which further reflects the civilized construction of modern construction sites, especially in terms of rapid installation and putting into use, and has obvious advantages in terms of assemblability and disassembly, and the turnover and reuse index of materials. Significantly reducing the cost of temporary facilities and construction cycles on construction sites is an indispensable new lightweight building material.

Summarize

In short, sandwich panels are a building material with comprehensive functions and excellent performance. They have the advantages of good thermal insulation, waterproofness and fireproofing, and easy construction. It is widely used in building walls, roofs, partitions, ceilings and other fields.

Sandwich Steel Panel Manufacturer

Wanzhi is a company with many years of experience in sandwich steel panels production. Here you can choose the product that best suits your project. We provide the most affordable exM-factory price. Looking forward to your inquiry.