Seamless steel pipe

What is seamless steel pipe ?

Seamless steel pipe is a long steel strip with a hollow cross-section and no seams around it. It is made by punching a whole round steel bar, and there is no weld on the surface of the steel pipe, which is called a seamless steel pipe.

Seamless steel pipes have a hollow structure and can be used as pipelines for conveying fluids, such as pipelines for conveying oil, natural gas, coal gas, water and certain solid materials.

Classification of seamless steel pipe

According to the production method, seamless steel pipes can be divided into hot-rolled seamless steel pipes, cold-rolled seamless steel pipes, cold-drawn seamless steel pipes, extruded seamless steel pipes, jacking pipes, etc.

Steel pipes can be divided into round pipes and special-shaped pipes according to the shape of their cross-sectional area. Special-shaped tubes come in a variety of complex shapes, such as square, oval, triangle, hexagon, melon seed, star, and winged tubes.

According to different uses, seamless steel pipes can be divided into thick-walled seamless steel pipes and thin-walled seamless steel pipes. It can also be divided into two categories: general purpose (used for water supply, gas pipelines and structural parts, mechanical parts) and special purpose (used for boilers, geological exploration, bearings, acid resistance, etc.).

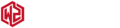

Hot rolled seamless steel pipe

Seamless steel pipe direct

The materials of seamless steel pipes include ordinary and high-quality carbon structural steel (Q215-A~Q275-A and 10~50 steel), low alloy steel (09MnV, 16Mn, etc.), alloy steel, stainless acid-resistant steel, etc.

Production process of seamless steel pipe

The production methods of seamless steel pipes are roughly divided into oblique rolling method (Monnesmann method) and extrusion method.

The oblique rolling method (Monnesmann method) is to first perforate the tube blank with an oblique rolling roller and then extend it with a rolling mill. This method has a fast production speed, but has high requirements on the machinability of the tube blank. It is mainly suitable for the production of carbon steel and low alloy steel pipes.

The extrusion method is to use a piercing machine to pierce the tube billet or ingot, and then use an extruder to extrude it into a steel pipe. This method is less efficient than the oblique rolling method and is suitable for the production of high-strength alloy steel pipes.

Both the cross-rolling method and the extrusion method require the tube blank or ingot to be heated first, and the steel pipe produced is called a hot-rolled tube. Steel pipes produced by hot processing methods can sometimes be cold processed as needed. There are two cold processing methods: one is cold drawing and the other is cold rolling. Cold processing of seamless steel pipes can improve the dimensional accuracy and processing finish of steel pipes and improve the mechanical properties of materials.

Seamless steel pipe application areas

Compared with solid steel such as round steel, seamless steel pipes is lighter in weight when the bending and torsional strength are the same. It is an economical cross-section steel and is widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipes, automobile transmission shafts, bicycle frames, and steel scaffolding used in construction. Using seamless steel pipes to manufacture annular parts can improve material utilization, simplify manufacturing processes, save materials and processing time, such as rolling bearing rings, jack sleeves, etc., which are widely made of steel pipes.

The following are some special steel pipes

Steel pipe for structure is a seamless steel pipe used for general structure and mechanical structure.

Seamless steel pipes for fluid transportation is a general seamless steel pipes used for conveying fluids such as water, oil and gas.

Special steel pipe

Transportation pipe

Seamless steel pipes for petroleum cracking is a steel pipe for furnace tubes, heat exchangers and pipelines in petroleum refineries.

Diamond core drilling seamless steel pipes are seamless steel pipes for drill pipes, core rods and casings used for diamond core drilling.

High-pressure oil pipe for diesel engine is a cold-drawn steel pipes for manufacturing high-pressure pipe of diesel engine injection system.

Precision inner diameter seamless steel pipes for hydraulic and pneumatic cylinder is a cold-drawn or cold-rolled precision seamless steel pipe with precise inner diameter for manufacturing hydraulic and pneumatic cylinder.

Seamless steel pipes have many other special uses, which are not listed here one by one. If you need to purchase seamless steel pipes, you can consult us. Our business manager will provide you with professional explanations and affordable quotations.

Determinants of quality & price of seamless steel pipes

Factors affecting the quality of seamless steel pipes

Raw material quality: The main raw material of seamless steel pipe is steel, and its quality directly affects the quality of the finished product of seamless steel pipe.

Production process: Advanced production process can ensure that the performance indicators of seamless steel pipe meet the standard requirements during the manufacturing process, and stable production process can reduce fluctuations in the production process and improve the stability of product quality.

Production equipment: Advanced production equipment can accurately control various parameters in the production process to ensure that the dimensional accuracy and surface quality of seamless steel pipes meet the standard requirements.

Quality control system: Through strict quality inspection and testing, problems in the production process can be discovered and corrected in a timely manner to ensure that the quality of seamless steel pipes meets the standard requirements.

Determinants of seamless steel pipe prices

Raw material cost: The raw material cost of seamless steel pipe is one of the most important factors affecting its price. When the price of raw materials such as steel rises, the production cost will also increase accordingly, thus driving up the price.

Market demand and supply: The market supply and demand relationship is the core factor that determines the price. When the market demand is greater than the supply, the price tends to rise; conversely, the price will fall.

Automobile half shaft steel pipe

High pressure steel pipe

Production process and cost: Advanced and efficient production processes can reduce production costs and improve production efficiency, thereby affecting market prices.

Brand and reputation: Seamless steel pipes produced by well-known brands and companies with good reputations tend to gain higher market recognition and premium space.

Macroeconomic and policy environment: The macroeconomic situation and policy environment will also affect the price of seamless steel pipes.

In summary, the quality and price of seamless steel pipes are jointly affected by many factors. When purchasing seamless steel pipes, customers should consider the above factors comprehensively in order to choose products with high cost performance.

Seamless Steel Pipe Supplier

Choosing a good supplier is the most important step in foreign trade procurement. A large price difference in quotation is definitely abnormal. Due to unchangeable factors such as raw materials and market environment, other factors that affect prices have little impact on prices, so basically normal supplier quotations will not differ much, unless the supplier is a liar, providing defective products, or not shipping enough, or even worse, cheating on deposits. In China, it is common knowledge that you will suffer a great loss if you are greedy for small gains; there is no such thing as a free lunch, etc.

Wanzhi Company is a comprehensive steel company integrating steel manufacturing, processing and sales. Our steel pipe products are produced and sold in many countries around the world. Our customers include individuals, dealers, factories, and governments. We have a large number of fixed long-term customers, and there are many returning customers every month. If you have the need to purchase seamless steel pipes or other steel products, we look forward to your inquiries, and you can also visit the factory.