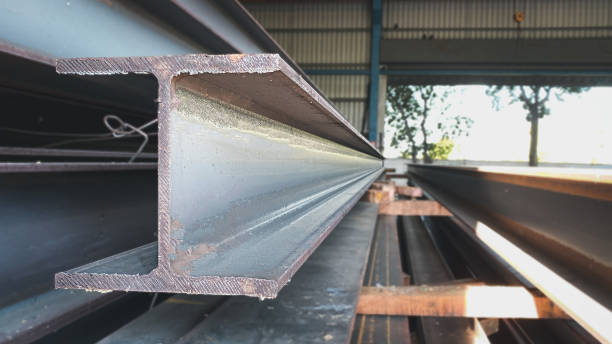

H-beam

What is H-beam steel?

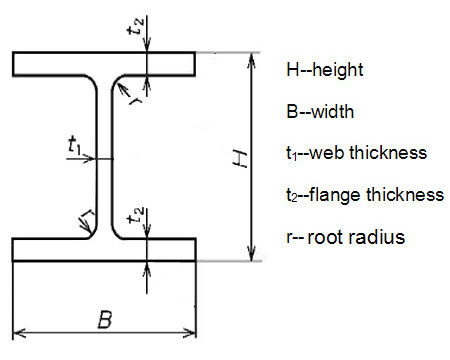

H-beam, named after its cross-sectional shape resembling the English letter “H”. It is also known as universal steel beam, wide flange I-beam, or parallel flange I-beam. The inner side of its legs has no slope, and compared with traditional I-beams, it has superior cross-sectional characteristics. It is widely used in fields such as construction, machinery, and bridges.

Structural characteristics

Wing edge: The inner and outer sides of the wing edge are parallel or nearly parallel, and the end of the wing edge is at a right angle, which gives it good bending resistance in all directions.

The relationship between belly plate and flange: The thickness of the belly plate is smaller than that of ordinary I-beams with the same height as the belly plate. It’s width of the flange is larger than that of ordinary I-beams with the same height as the belly plate. Therefore, under the same weight, the section modulus, moment of inertia, and corresponding strength of H-beams are significantly better than those of ordinary I-beams.

H-beams Specifications

| Artículo | Parámetros del producto |

| Nombre | H-beam,H-shaped steel,Universal Beam |

| Estándar | ASTM, AISI, GB, JIS, DIN, BS |

| Solicitud | Construction, bridges, industrial equipment, machinery manufacturing |

| Common materials | carbon steel,stainless steel,Alloy steel |

| Material | Q235B, SM490, SS400, Q345B, etc. |

| Advantage | Large cross-sectional modulus, light weight, and metal saving |

| Classification | Hot rolled H-beam, welded H-beam (H) |

| Longitud | Customizable |

| Cantidad mínima de pedido | 10 toneladas |

| HS Code | 72163319 |

| Ciclo de entrega | Within 2 weeks after payment |

| Paquete de transporte | Standard Packing |

Classification method of H-beam

The flange width

It can be divided into wide flange H-beam (HW), medium flange H-beam (HM), and narrow flange H-beam (HN). The flange width b of wide and medium flange H-beams is greater than or equal to the web height h, while the flange width b of narrow flange H-beams is approximately equal to half of the web height h.

Product usage

Divided into H-shaped steel beams, H-shaped steel columns, H-shaped steel piles, extremely thick flange H-shaped steel beams, etc. Sometimes parallel leg channel steel and parallel flange T-shaped steel are also included in its scope.

Cold rolled H-beam

Galvanized H-beam

Production methods

There are welded H-shaped steel and rolled H-beams. Among them, rolling H-beams is divided into hot rolling and cold rolling, with hot rolling is the main method. Welding H-beams is achieved by cutting and splicing steel plates according to the predetermined cross-sectional dimensions of H-beams, and then using welding techniques to weld the steel plates together.

Size specifications

Products with a web height h of 700mm or more are usually referred to as large, 300-700mm as medium, and less than 300mm as small.

Advantages of H-beam performance

1. High structural strength:

H-shaped steel has a large section modulus, and compared with ordinary I-beams of the same weight, it has a stronger bearing capacity, which can save 10-15% of metal.

2. Flexible design style:

With the same beam height, the spacing of H-shaped steel structures can be 50% larger than that of concrete structures, making the building layout more flexible.

3. Lightweight:

Compared with concrete structures, H-shaped steel structures have a lighter self weight, reducing internal forces in structural design and lowering construction difficulty and cost.

Hot rolled H-beam

Low carbon H-beam

4. High structural stability:

H-shaped steel have good plasticity and flexibility, high structural stability, and are suitable for building structures that can withstand large vibration and impact loads.

5. Increase effective usable area:

Due to the small cross-sectional area of H-shaped steel columns, the effective usable area of the building can be increased by 4-6% depending on the different forms of the building.

6. Convenient construction:

Due to its various parts being arranged at right angles and having a regular shape. It is easy to assemble and combine into various components, which can save about 25% of welding and riveting work and greatly accelerate the construction speed and shorten the construction period.

7. Environmental Protection:

H-beams can be constructed using dry methods, resulting in minimal noise and dust; At the same time, the reduction of self weight reduces the amount of soil taken for foundation construction, resulting in minimal damage to land resources; After the service life of the building structure expires, the recycling value of scrap steel resources is high.

The Application of H-beam

In the field of architecture: It is widely used in various civil and industrial building structures, such as large-span industrial plants, modern high-rise buildings, etc. It can be used to make load-bearing components such as beams, columns, and brackets.

Steel beam H-beam

Factory stock

Bridge engineering: used for large bridges that require high load-bearing capacity, good cross-sectional stability, and large spans; Serving as the main load-bearing components such as bridge deck beams and bridge supports.

Industrial equipment: used in industries such as petrochemicals and power to manufacture various equipment structures, support structures for heavy equipment, etc.

Mechanical manufacturing: can be used to manufacture support structures and transmission components for vehicles, support structures for ship hulls and decks, as well as other mechanical components such as columns, beams, gears, and bearing seats.

Infrastructure: plays an important role in the construction of infrastructure such as highways, mine support, foundation treatment, and dam engineering.

Production process of H-beam

The production process of H-beams mainly includes material selection and pretreatment, cutting and straightening, heating to plastic state, rolling forming (or welding forming), straightening and finishing, surface treatment, and comprehensive testing. Each stage requires strict control of process parameters and quality standards to ensure that the quality and performance of the final product meet relevant requirements.

In summary, H-shaped steel is a type of steel with excellent performance and broad application prospects. With the advancement of technology and continuous improvement of processes, H-beams will play their unique role in more fields.

Narrow wing edge

H-shaped steel

H-beam Steel Supplier Manufacturer

H-beam is one of the many products of Wanzhi Steel. We have advanced production equipment and exquisite craftsmanship, and are committed to creating high-quality H-beam products. The product specifications are complete and widely used in fields such as construction, bridges, and machinery manufacturing. With high-quality products, efficient services, and good reputation, it has won the trust and praise of customers. Welcome to consult, my professional team will help you solve related problems.