I-beam

What is I-beam steel?

I-beam is a type of steel profile, also known as Universal Beam. It is a long strip of steel with an I-shaped cross-section – hence the name “I-beam“. According to the Euler–Bernoulli beam theory, this structure has strong bending and shear stiffness but poor torsional stiffness.

I-beam Galvanizing

Q335B I-beam

Specifications of I-beam

The specifications and models of I-beams are expressed in millimeters as waist height (h) x leg width (b) x waist thickness (d). For example, “150 x 66 x 8” means I-beams with a waist height of 150 millimeters, leg width of 66 millimeters, and waist thickness of 8 millimeters.

I-beams can also be numbered to indicate the main dimensions of the specification. For example, a No. 20 I-beam indicates that its height is 20cm. If the I-beams have the same height, the angle code a, b or c can be added after the number to indicate it, such as 32a, 32b, 32c, etc.

Specifications

| Artículo | Specifications/models | Parameter |

| Ordinary I-beam | Specification range | Waist height 100~630mm, leg width 63~180mm, waist thickness 4.5~18mm |

| Common models | 10#, 12#, 14#, 16#, 18#, 20#, etc., the corresponding waist heights are 100mm, 120mm, 140mm, 160mm, 180mm, etc. | |

| Lightweight I-beam | Specification range | The specification range is similar to that of ordinary I-beams, but the flanges are narrower and the webs are thinner. |

| Common models | The correspondence between common models and waist height is the same as that of ordinary I-beams, but the leg width and waist thickness are different. | |

| H-beam | Specification range | Waist height 100~800 mm, flange width 50~200 mm, web thickness 6~30 mm |

| Common models | HW series, HM series, HN series, etc., each series has multiple specifications |

Classification of I-beam

Classified by cross-sectional form

According to the different cross-sectional forms, I-beams can be divided into ordinary I-beams, wide edged I-beams, and H-shaped I-beams. Among them, ordinary I-beams are a common type with high strength and stiffness, suitable for various building and mechanical structures. Wide edged I-beams have greater bending strength and load-bearing capacity, making them suitable for structures and bridges that require larger spans. H-shaped I-beams have higher cross-sectional modulus and load-bearing capacity, making them suitable for structures and components that require greater load-bearing capacity.

Classified by Material

According to different materials, I-beams can be divided into carbon structural steel, alloy structural steel, stainless steel, etc. Among them, carbon structural steel is a commonly used type with good plasticity, toughness, and welding performance, suitable for various building and mechanical structures. Alloy structural steel has higher strength and hardenability, making it suitable for structures and components that require greater load-bearing capacity. Stainless steel has good corrosion resistance and high temperature resistance, and is suitable for various corrosive and high temperature environments.

Alloy structural steel

30# I-beam

Other classification methods

- Classified by height

The height range of I-beams is from 100mm to 900mm, and they can be divided into different models according to height, such as 8 #, 10 #, 12 #, etc - Classified by thickness

The thickness of I-beams usually ranges from 5mm to 25mm, and can be divided into different specifications according to thickness - Classified by length

The length of general I-beams is 6 meters, 9 meters, 12 meters, etc., which can be divided into different specifications according to their length - Classified by processing method

I-beams can be processed through hot rolling, cold bending, welding, and other methods, and can be divided into different types according to the different processing methods - Classified by the ratio of flange to web height

Wide, medium, and narrow flange I-beams

In general, different types of I-beams have their own characteristics and applicable scenarios. When choosing, you need to consider the specific engineering requirements and conditions. At the same time, with the development of science and technology and the advancement of production technology, the types and performance of I-beams are also constantly optimized and improved to meet the needs of more complex and demanding engineering environments.

Performance characteristics of I-beam

Strong compressive resistance: I-beams have a large transverse cross-section and can withstand greater pressure, making them suitable for beam and column building structures.

I-beam Stainless steel

High compression I-beam

Good bending resistance: I-beams are precisely designed and manufactured, and their bending degree meets project standards. They can always maintain good shape and quality under bending loads, and are often used as parts in bridges, machinery manufacturing, and aerospace fields.

Stable chemical composition: I-beams have a stable chemical composition and do not contain harmful elements. They are safe and reliable to use, have more stable quality, and are more widely applicable.

Application fields of I-beam

Building structures: I-beams are often used as materials for building structures such as beams, columns, stairs and platforms. Their high strength and strong compressive resistance make the buildings strong and durable.

Bridges: I-beams are often used as bridges and parts on bridges, such as railings, beams, columns and pedestals. Their high strength and good bending resistance make bridges more stable and safe.

Machinery manufacturing: I-beams are widely used in the manufacture of various mechanical parts, such as automobile chassis, lifting and transportation machinery, etc.

Other fields: I-beams are also used in the fields of brackets, platforms, pipe brackets, as well as high-tech fields such as aerospace and shipbuilding.

Building Applications

Steel frame structure

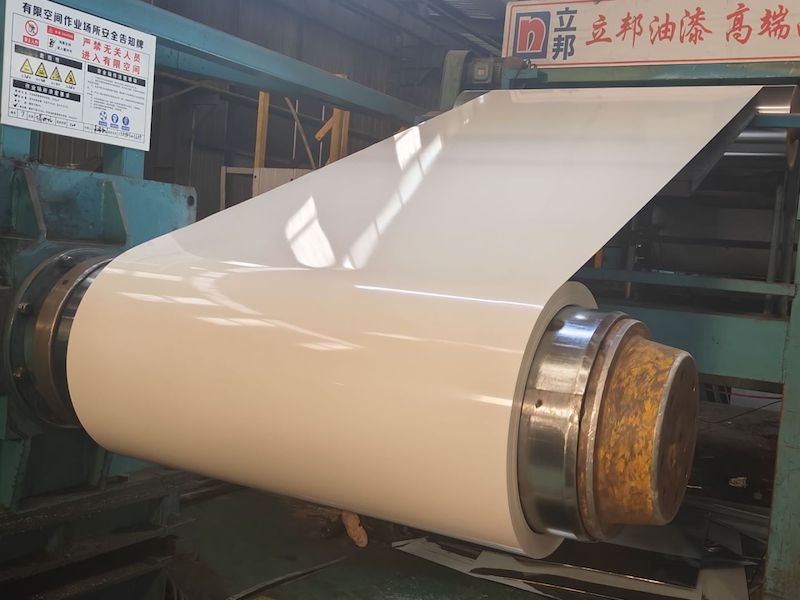

I-beam steel Manufacturers & Suppliers

Wanzhi Steel is a renowned manufacturer and supplier of I-beams (also known as H-beams or wide flange steel). Founded in 2011, the company is headquartered in Zhengzhou, China, with a factory in Binzhou, Shandong. We specialize in high-quality steel products that are widely used in a variety of construction and industrial applications. Our I-beams are known for their strength, durability, and precision, making them ideal for supporting structures in buildings, bridges, and other infrastructure projects.

Wanzhi Steel is committed to meeting the diverse needs of its customers and offers a wide range of sizes and specifications to meet different requirements. Customers from all countries are welcome to inquire and place orders.

Notes

When choosing: the appropriate specifications and types should be selected according to the specific use environment and stress conditions. For example, in situations where large bending moments and shear forces need to be borne, H-shaped steel with larger cross-sections and wider flanges should be selected.

Quality inspection: When purchasing and using I-beams, their quality should be inspected to ensure that they meet relevant standards and requirements. The main inspection items include dimensional deviation, surface quality, mechanical properties, etc.