PVDF vs SMP Coated Roof Definition

PVDF Coated Steel

PVDF (polyvinylidene fluoride) coating is a high-performance, pre-painted steel sheet containing at least 70% PVDF resin. High-temperature baking forms a dense protective layer, specifically designed for roofs used in extreme climates.

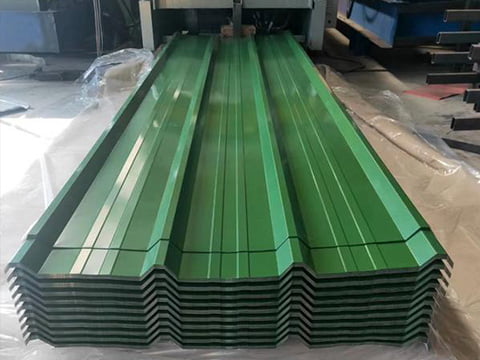

SMP Coated Steel

SMP (silicone modified polyester) coating is a modified polyester pre-painted steel sheet containing silicone resin. It offers a lower cost and is suitable for industrial/agricultural roofs used in short- to medium-term applications.

PVDF vs SMP Coating Performance Comparison

| Features | PVDF Coating | SMP Coating |

| Weather Resistance | Extreme (25+ years, ΔE<5 fade) | Medium (10-15 years, ΔE<8 fade) |

| Salt Spray Test | 1,500+ hours (suitable for coastal areas) | 500-800 hours (suitable for inland areas) |

| Self-Cleaning | Hydrophobic Angle >110° (reduced maintenance) | Hydrophobic Angle <90° (regular cleaning required) |

| UV resistance | Extremely strong (suitable for desert/high-altitude areas) | Moderate (avoid long-term exposure to sunlight) |

| Flexibility | Lower (more suitable for fixed structures) | Higher (resistant to bending and suitable for lightweight roofs) |

| Chemical resistance | Acid rain and industrial waste gas (according to ASTM D2244) | Only resistant to weak acid and alkali (avoid use near chemical plants) |

| Color Contrast | High Gloss/Metallic | Matte/Solid Color |

PVDF vs SMP Cost-effectiveness Comparison

PVDF

Initial Cost: 20-30% More Expensive Than SMP

Lifecycle Cost: Lower (25 Years Without Replacement)

Suitable Projects: PV Mounting Systems for High-End Buildings (Hotels, Landmarks)

SMP

Initial Cost: Economical Choice

Lifecycle Cost: Higher (Mid-Term Replacement Required)

Suitable Projects: Temporary Warehouses, Agricultural Greenhouses

How to choose? Recommended by Scene

Select PVDF based on the following conditions:

- The project is located in high UV/high salt spray areas (such as the Middle East and Southeast Asia)

- Requires color persistence (such as brand identity buildings)

- Adequate budget, long-term investment return

Select SMP based on the following conditions:

- Short term use (<10 years) or limited budget

- Simple color requirements (such as white, gray)

- Inland low corrosion environment

Resumen

In summary, PVDF coated steel (polyvinylidene fluoride) has excellent weather resistance (over 25 years of service life), self-cleaning function, and high corrosion resistance (salt spray test for 1500+hours), making it suitable for high-end buildings and harsh environments (such as coastal areas and deserts); SMP coated steel (silicon modified polyester) has lower cost and better flexibility, but weaker weather resistance (10-15 years lifespan, salt spray 500-800 hours), making it suitable for budget limited inland projects or short-term buildings (such as warehouses, agricultural greenhouses). PVDF is suitable for long-term investment, while SMP focuses on economic practicality.