Carbon steel and stainless steel each have their own strengths. Carbon steel, also known as carbon steel, typically has a carbon content range of 0.0218% to 2.11% (mass fraction). When the carbon content exceeds 2.11%, it is generally referred to as cast iron. Stainless steel belongs to alloy steel, and its core alloying element is chromium (Cr, usually ≥ 10.5%). The carbon content of stainless steel ranges from 0.03% to 0.15% (mass fraction), and some ultra-low carbon stainless steels (such as 304L and 316L) even have a carbon content of ≤ 0.03%. Stainless steel, also known as “inox steel” (French “inoxydab” means “non oxidizable”), truly lives up to its name and has strong resistance to corrosion and staining.

Core differences between carbon steel and stainless steel

The fundamental difference between the two lies in their chemical composition:

Carbon steel: The main components are iron (97-99%) and carbon (0.05-2.1%), with trace amounts of silicon, manganese, and copper. The higher the carbon content, the greater the hardness but the lower the ductility.

The Stainless steel: contains iron, carbon, and at least 10.5% chromium (Cr), with some types adding elements such as nickel (Ni), molybdenum (Mo), manganese (Mn), etc. Chromium forms a chromium oxide protective layer, endowing it with corrosion resistance. Common classifications include austenitic, martensitic, ferritic stainless steel, etc.

Comparison of Corrosion Resistance and Durability

Stainless steel:

Excellent performance in humid, acidic, or marine environments is attributed to its chromium oxide protective layer.

Resistant to most chemicals (except hydrochloric acid) and requires almost no maintenance.

Carbon steel:

Easy to rust and oxidize, it needs to be protected by painting, galvanizing or epoxy coating.

Untreated carbon steel is not suitable for marine environments.

Stainless steel castings

Carbon steel gears

Mechanical properties: strength vs toughness

| Performance | Carbon steel | Stainless steel |

| Tensile strength | 370-1500 MPa (higher strength) | 520-1500 MPa (varies by grade) |

| Hardness | 120-300 HB | 150-350 HB |

| Ductility | 10-30% elongation | 30-50% elongation |

| Thermal conductivity | 36-54 W/m · K | 16-24 W/m · K |

Carbon steel performs better in high stress structural applications such as bridges and beams due to its rigidity and wear resistance.

Stainless steel has better impact resistance and toughness, making it suitable for dynamic loads such as automotive exhaust systems.

Application Area

Carbon steel:

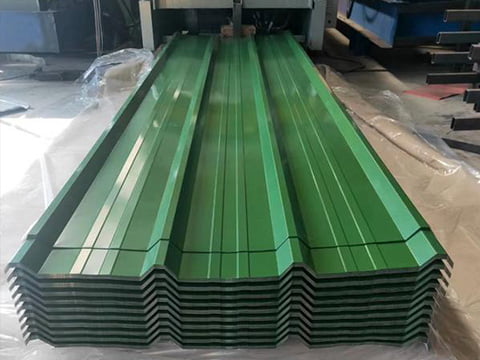

Building structures (bridges, steel bars), mechanical parts (gears, shafts), tools (hammers, knives).

Daily necessities: car body, pipes, bolts.

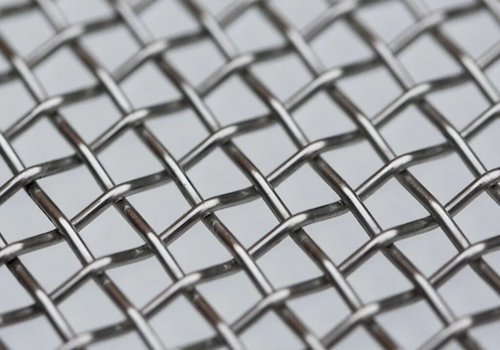

Stainless steel embossed mesh

Stainless steel pipe

Stainless steel:

Corrosion resistant scenarios: food processing equipment, medical devices, chemical pipelines, kitchen utensils.

High end fields: surgical instruments, architectural decoration, marine engineering.

Carbon steel round steel

Threaded steel bars

Other differences

Magnetism: Carbon steel usually has magnetism; Austenitic stainless steel (such as 304) is non-magnetic, while ferritic/martensitic stainless steel is magnetic

Sustainability: Carbon steel is easy to recycle but has a short lifespan; Stainless steel has a long lifespan but high production energy consumption

How to Choose: Three Decision Factors

According to the environment:

Corrosive or high humidity environment → Stainless steel.

Dry controllable conditions → Carbon steel.

Consider budget:

Short term project → Carbon steel.

Long term investment → stainless steel.

Performance requirements:

High strength and wear resistance → Carbon steel.

Aesthetic and hygiene requirements → Stainless steel.

Summary of Carbon Steel and Stainless Steel

Carbon steel can refer to two different types of steel: traditional carbon steel and low-alloy steel.

Application of Carbon Steel and Stainless Steel

Compared with low-carbon steel, stainless steel has significantly improved strength, hardness, and corrosion resistance. High carbon steel has a strength comparable to stainless steel, sometimes even surpassing it, but in the manufacturing industry, it is a niche material with a low range of applications. Unlike any carbon steel, stainless steel can survive and develop in corrosive or humid environments without oxidation. But carbon steel is much cheaper than stainless steel and is more suitable for manufacturing large structural components such as pipes, beams, and rolled steel plates.

Low alloy steel is superior to carbon steel in many aspects, but its corrosion resistance is poor. It can effectively match the material properties of stainless steel in some aspects, and alloys like 4140 and 4340 are often processed and used in many applications where even slight oxidation does not cause damage. Stainless steel is a more advanced material that is more suitable for industrial operations that do not require high quality parts.