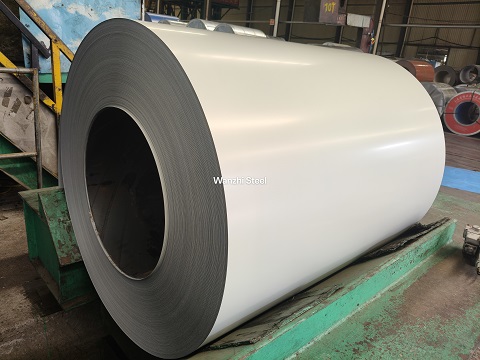

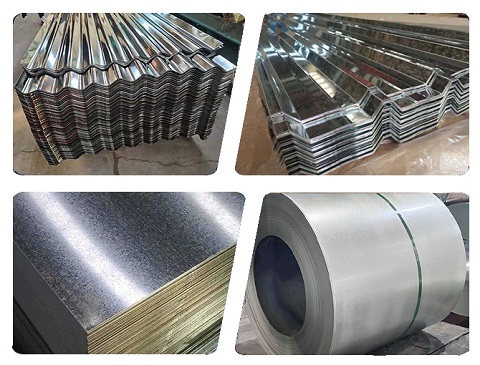

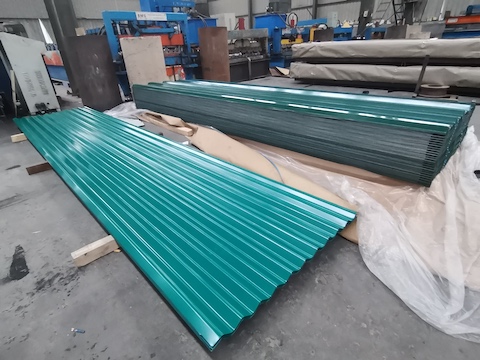

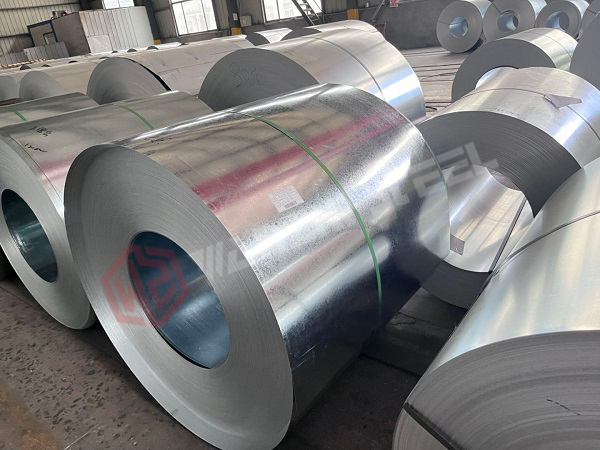

120 ton from UAE! RAL9004 PPGI strip steel + Z275 GI sheet

The United Arab Emirates, especially important cities such as Dubai and Abu Dhabi, has developed rapidly in the construction and manufacturing industries in recent years, which is one of its core strategies to promote economic diversification and reduce dependence on oil. The RAL9004 PPGI strip steel and galvanized steel plate purchased by the UAE factory customer this time are for use in the local construction industry. Product Introduction The high temperature, high humidity, strong ultraviolet radiation, and sandstorm climate in the United Arab Emirates have put forward special requirements for the steel used in its construction and manufacturing industries. In order to withstand the challenges of these harsh environments, local […]

120 ton from UAE! RAL9004 PPGI strip steel + Z275 GI sheet 続きを読む »