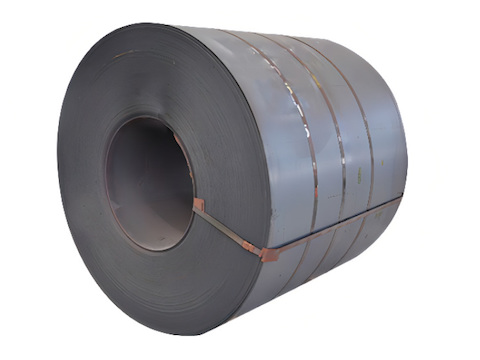

Cold Rolled Steel

Width: 600–1500 mm

Thickness: 1.5 – 20mm

Design Style: Customizable

Product Introduce

Cold Rolled Steel is a high-precision steel made from hot-rolled steel coils through room temperature rolling, annealing and other processes.

Its core advantages:

Surface quality: smooth and scale-free (Ra≤1.6μm), can be directly used for precision manufacturing.

Mechanical properties: yield strength increased by 20%-50% (such as SPCC cold-rolled plate can reach ≥280MPa), and deep drawing performance is excellent (elongation 30%-45%).

Dimensional accuracy: thickness tolerance ±0.03mm, suitable for high-precision scenarios such as automotive panels.

Processing adaptability: supports surface treatment such as electrogalvanizing and spraying to meet diverse corrosion resistance needs.

International standard comparison

Chinese GB standards: DC01 (yield strength ≤ 280MPa), DC04 (yield strength ≤ 210MPa), DC07 (yield strength ≤ 150MPa)

American standard ASTM: CS/DS/DDS/EDDS series (such as CS grade yield strength of 140-275MPa)

Japanese standard JIS: SPCC (ordinary grade), SPCE (deep drawing grade)

German standard DIN: ST12 (corresponding to DC01), ST14 (corresponding to DC04)

Product Parameters

| Item | Parameters |

| Products name | Cold Rolled Steel |

| Standard Specifications | ASTM, JIS, GB, EN, etc. |

| Thickness | 0.12~6.0mm (regular grade) |

| Width | 20-1500mm (standard cold-rolled coil), customizable up to 2000mm |

| Length | Customized according to customer requirements |

| Surface treatment | 2B (cold rolling+acid washing), BA (bright annealing), No.4 (wire drawing treatment) |

| Processing services | Support cutting, welding, punching, bending, unwinding, etc. |

| Application areas | Applicable to precision processing, such as automotive plates, home appliance plates, etc. |

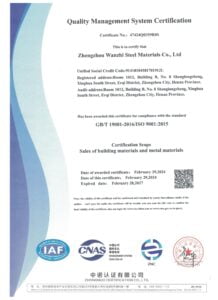

| Certification | ISO 9001, CE, SGS, etc. |

| Coil weight | 3-8 tons, customizable |

| MOQ | 10 tons |

| Delivery time | 5-14 days for conventional products, negotiated for customized products |

| Payment Term | T/T,100% L/C at sight |

| Packing | Standard seaworthy wooden box or steel strapping |

Application Fields and Common Cases

Cold rolled steel, with its performance advantages, is widely used in multiple core industries:

- Automotive industry

Body covering: DC04 deep drawn steel (0.6-1.2mm thick) is used for doors, engine hood, etc.

Safety structural components: HC340/590DP high-strength steel (tensile strength ≥ 590MPa) is used to make anti-collision beams. - Home appliance manufacturing

Precision components: Cold rolled sheet galvanized (with a zinc layer of 60g/m ²), used for refrigerator side panels and air conditioning heat sinks.

Appearance design: Color coated galvanized cold-rolled sheet (PVDF coating ≥ 20 μ m) enhances product aesthetics. - Architecture and Machinery

Light steel structure: C-shaped cold-rolled steel (1.5-3.0mm thick) reduces building weight by 30%.

Tool mold: SK5 high carbon cold-rolled steel with a hardness of ≥ HRC60 after quenching, used for cutting tools.

Our Certificates

Customer visit

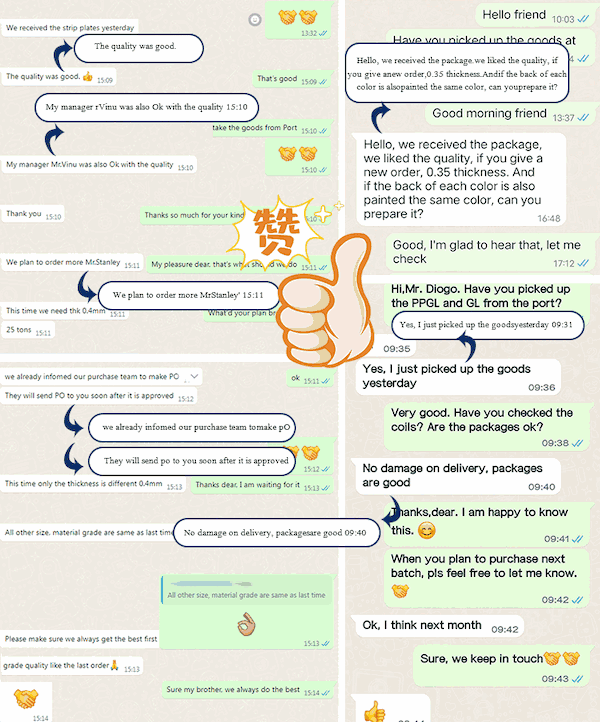

Customer affirmation

Why choose us ?

We are an integrated industrial and trade company that can produce steel independently and reduce costs.

From raw materials to finished products, we control quality throughout the process to ensure that the products meet customer requirements.

The combination of production and sales confidentiality can respond to orders quickly and shorten delivery time.

One-stop service, from consultation to production, and finally to after-sales service, provides all-round support.

We are self-produced, reducing dependence on external price fluctuations. In the face of sudden price increases, we can still deliver quickly and on time.

For inventory steel, we can provide preferential prices.

Contact us

Factory: Binzhou City, Shandong Province, ChinaList item

Company: Erqi District, Zhengzhou City, Henan Province, China

E-mail: info04@wanzhisteel.com

WhatsApp: +86 18736065220

Website: https://wanzhisteels.com

Hot Tags: Cold Rolled Steel, CR carbon tool steel, JIS/ASTM steel, Cold Rolled Steel rust prevention method, manufacturers, suppliers, factory, low price, for sale