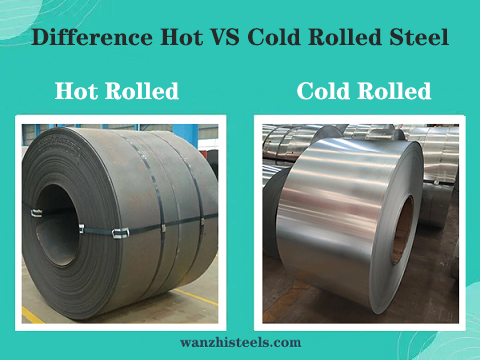

Hot and Cold rolled steel

Understand the main differences between hot and cold rolled steel Hot and cold rolled steel are fundamental materials in the metal processing and manufacturing industries. Choosing between them isn’t about which is better, but about selecting the right material for the specific job. Understanding their distinct properties, manufacturing processes, advantages, and limitations is crucial for designers, engineers, and purchasers. The Core Difference lies in when and how the steel is rolled to achieve its final specifications 1. Hot Rolled Steel (HR): Process: Steel is heated significantly above its recrystallization temperature (typically above 1700°F / 925°C) until it glows. It’s then passed through rollers at this high temperature. Result: Easier shaping, […]

Hot and Cold rolled steel 続きを読む »