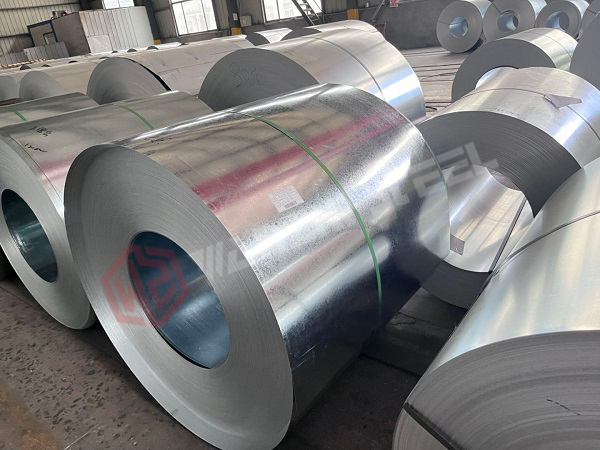

Astm A653 g90 galvanized steel

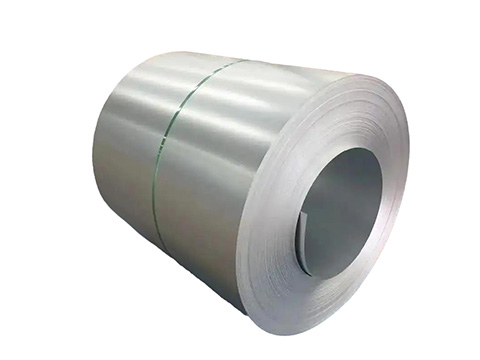

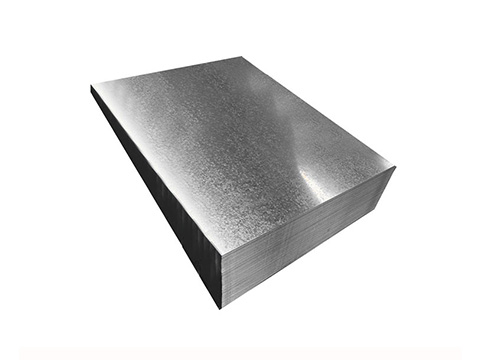

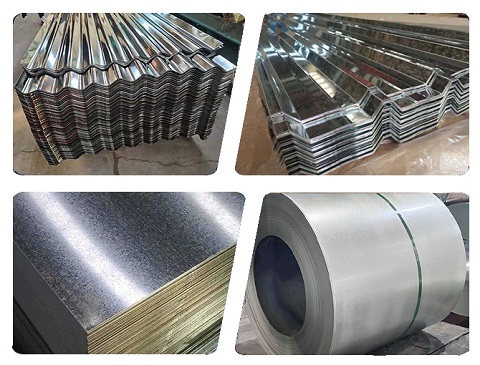

Home » GI/GL/Tin » Astm A653 g90 galvanized steel Astm A653 g90 galvanized steel Width: 600-1500mm Thickness: 0.12-4.0mm Coating: 90 oz/ft², 275g/m² Design Style: Customizable Product Introduce ASTM A653 G90 galvanized steel refers to the ASTM A653 specification. The zinc coating code G90 indicates that the total zinc coating density on both sides is 0.9 oz/ft² (average minimum value of three points on both sides) or 0.8 oz/ft² (minimum single point value on both sides). ASTM refers to the American Society for Testing and Materials. A-653 is one of its sub-standard numbers. ASTM A653 is the standard specification for hot-dip galvanized iron alloys or galvanized steel sheets. The core advantage of […]

Astm A653 g90 galvanized steel 続きを読む »