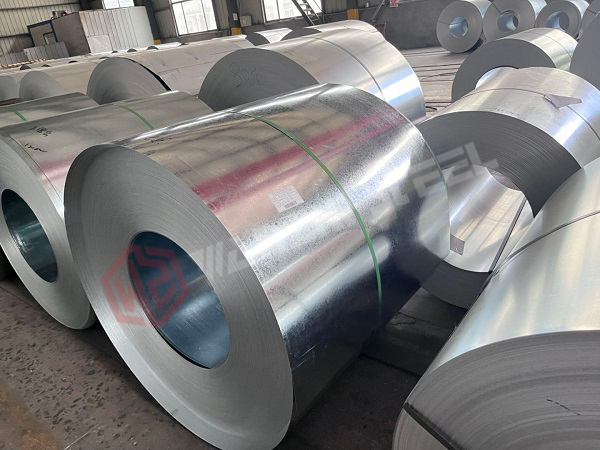

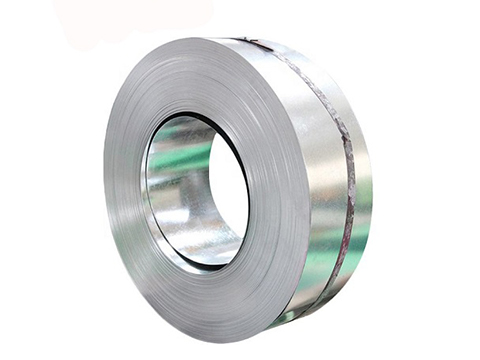

150 ton PPGI coil z275 galvanized sheet delivered perfectly

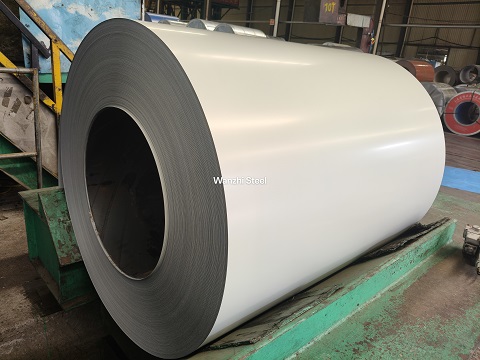

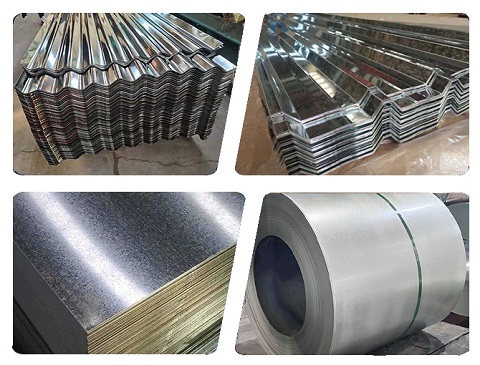

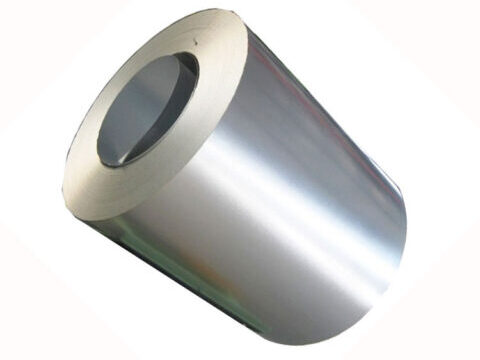

Chinese excellent steel supplier Wanzhi Steel, with its coastal anti-corrosion technology and Beirut Port customs clearance line, helps Lebanese builders shorten their construction period by 30 days! Customer Name LEMATIC Project Manager Thumbs Up: “From signing the contract to receiving the goods, it only takes 50 days, and Wanzhi Speed is rewriting the speed of the Middle East supply chain Product Introduction The RAL9003 PPGI steel coil substrate is made of galvanized steel sheet (GI), with common materials including DX51D, SGCC, etc. (carbon content ≤ 0.15%, yield strength ≥ 180MPa). The surface is coated with RAL 9003 (pure white) polymer coating, which can be selected from PE (polyester), SMP (silicon […]

150 ton PPGI coil z275 galvanized sheet delivered perfectly 続きを読む »