Wanzhi anti fingerprint Galvalume steel delivered Guyana

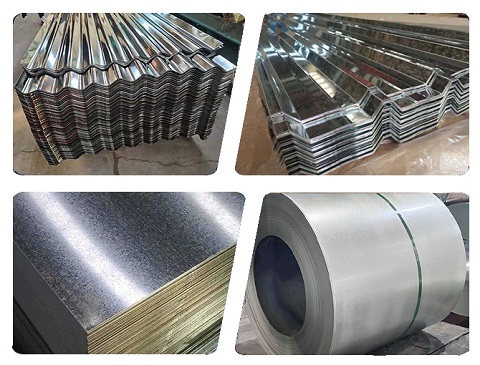

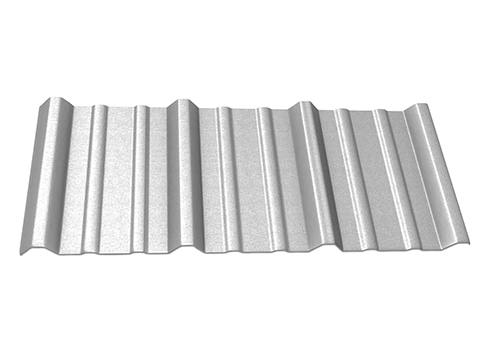

Guyana’s tropical maritime climate poses a severe challenge to building materials – high humidity and strong salt spray corrosion significantly reduce the lifespan of ordinary steel. Recently, Wanzhi Company provided green anti fingerprint galvalume steel coils for a high-end residential project in Georgetown, Guyana, which were highly recognized by customers for their excellent weather resistance and aesthetics. Product Introduction The green fingerprint resistant PPGL steel coil this time includes a triple protection system: 55% aluminum zinc alloy coating (compliant with ASTM A792 standard), nano anti fingerprint coating technology (reducing fingerprint residue by 90%), environmentally friendly green coating, perfectly adapted to the tropical climate environment of Guyana. RAL 6027 PPGL steel […]

Wanzhi anti fingerprint Galvalume steel delivered Guyana 続きを読む »