Stainless Steel

What is stainless steel ?

Stainless steel is the abbreviation of stainless acid-resistant steel. It is an alloy of iron and several other elements (such as nickel, chromium, molybdenum, and carbon) that is more corrosion-resistant than regular iron or steel (which is simply iron and carbon). According to the definition in GB/T20878-2007, stainless steel is steel with stainlessness and corrosion resistance as its main characteristics, and the chromium content is at least 10.5% and the carbon content does not exceed 1.2%.

Stainless steel

The main function of chromium is to form a dense oxide film to prevent oxygen and moisture from corroding the metal surface, thereby playing an anti-corrosion role. In addition, the addition of nickel can improve the corrosion resistance and plasticity of stainless steel.

Stainless steel specifications

| Item | Product Parameter |

| Name | Stainless steel |

| Material | main:201、304、316、316L、410、430 etc.

300 series: 301、302、303、304、304L、309、309s、310、310S、316、316L、316Ti、317L、321、347 200 series: 201、202、202cu、 204 400 series: 409,409L,410,420,430,431,439,440,441,444 other: 2205,2507, 2906,330,660,630,631,17-4ph,17-7ph,S318039 904L etc. Duplex stainless steel: S22053,S25073,S22253,S31803,S32205,S32304 Special stainless steel: 904L,347/347H,317/317L,316Ti、254Mo |

| Thickness | Cold rolled 3-300mm, Hot rolled 0.1-3mm |

| Width | 600 ~ 1500 mm,Width tolerance -0/+3mm |

| Lenght | 3mm-2000m/2438/3048mm , Customized according to customers |

| Precision | ± 0.1 mm |

| Standard | JIS, AISI, ASTM, DIN, TUV, BV, SUS, etc |

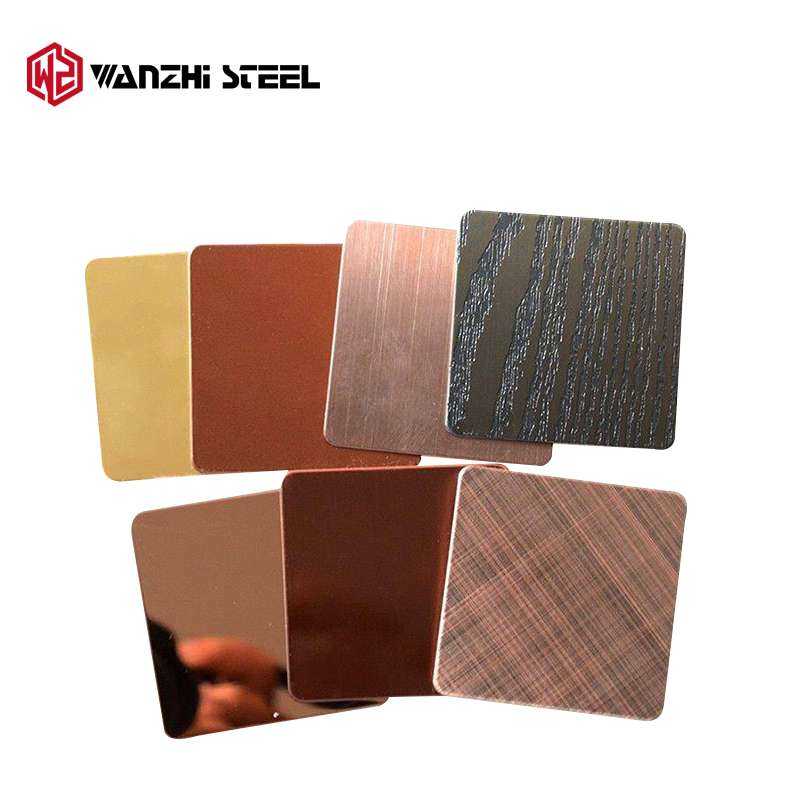

| Surface treatment | 2B, 2D, 4B, BA, HL, mirror, brush, NO, 1-NO, 4, 8K, etc. |

| Color | Gold, black, sapphire blue, brown, rose gold, bronze, purple, gray, silver, Champagne, violet, blue diamond, etc |

| Application | Construction, Medical, shipbuilding, vehicle manufacturing, machinery manufacturing, furniture and home appliances, electrical and automation. |

| Package | Standard Export Package |

How Stainless Steel Coil/Sheet is Made

Stainless steel structural composition

The corrosion resistance of stainless steel decreases with the increase of carbon content. Therefore, the carbon content of most stainless steels is low, not exceeding 1.2% at most. The Wc (carbon content) of some steels is even lower than 0.03% (such as 00Cr12).

The main alloying element in stainless steel is Cr (chromium). Only when the Cr content reaches a certain value, the steel will be corrosion-resistant. Therefore, the Cr (chromium) content of stainless steel is generally at least 10.5%. It also contains Ni, Ti, Mn, N, Nb, Mo, Si, Cu and other elements.

Stainless steel coil

Stainless steel pipe

As the chromium content in steel increases, the corrosion resistance of steel increases. When the chromium content reaches a certain proportion, a very thin, colorless, transparent, smooth chromium-rich oxide film will automatically form on the steel surface to prevent the steel from rusting. This film is very stable and will quickly repair itself even if it is damaged. It is called a self-passivating film.

The corrosion resistance of stainless steel depends on the alloying elements contained in the steel, and chromium is the basic element that makes stainless steel corrosion-resistant. In addition to chromium, commonly used alloying elements include nickel, molybdenum, titanium, niobium, copper, nitrogen, etc., to meet the requirements of stainless steel organization and performance for various uses.

Characteristics of stainless steel

It is a kind of material with a brightness close to that of a mirror, and a hard and cold touch. It is a relatively avant-garde decorative material with excellent heat resistance, weldability, corrosion resistance, compatibility, and toughness.

Kitchenware

Round bar

Weldability

Different products have different requirements for welding performance. Class I tableware generally does not require welding performance, even for some pot companies. However, most products require good welding performance of raw materials, such as Class II tableware, thermos cups, steel pipes, water heaters, water dispensers, etc.

Corrosion resistance

The corrosion resistance of stainless steel generally increases with the increase of chromium content. The basic principle is that when there is enough chromium in the steel, a very thin and dense oxide film is formed on the surface of the steel, which can prevent further oxidation.

Polishing property

Nowadays, in the production process of stainless steel products, polishing is a process that must be carried out, so this requires raw materials with better polishing performance.

Heat resistance

The heat resistance of stainless steel mainly refers to the ability of stainless steel to maintain excellent physical and mechanical energy at high temperatures. Carbon is an interstitial element that can significantly improve the strength of austenitic stainless steel through solid solution strengthening. Carbon can also improve the stress resistance and corrosion resistance of austenitic stainless steel in high-concentration chlorides. Therefore, using carbon as a raw material for stainless steel pipes can improve the heat resistance of stainless steel.

Application of stainless steel

Because of the unique characteristics and diverse classification of stainless steel, it is widely used in various fields. The following are several typical application fields:

Storage tank

Various POTS

Industrial field

In the chemical, petroleum, energy and other industries, stainless steel is often used to manufacture containers, pipes, heat exchangers and other equipment to withstand high temperature, high pressure and corrosive media.

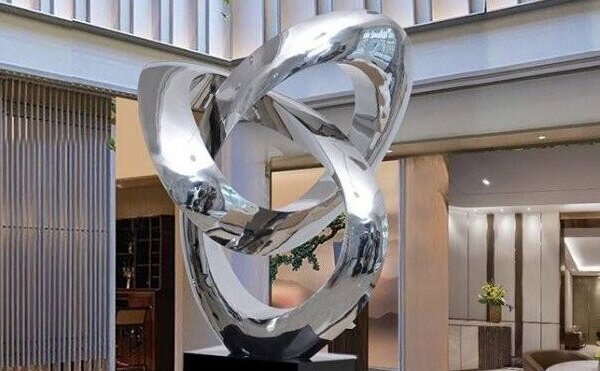

Construction field

Stainless steel has good weather resistance and aesthetics, and is widely used in architectural decoration, interior decoration, and structural materials such as bridges and columns.

Tableware

Sculptural building

Food processing field

Food-grade stainless steel materials meet hygiene standards and are widely used in food processing equipment, food storage containers, etc. to ensure food safety and hygiene.

Medical field

Stainless steel has antibacterial properties and biocompatibility, and is widely used in the manufacture of medical devices, surgical instruments, artificial joints, etc., to improve the reliability and durability of medical equipment.

As an important material, stainless steel has the characteristics of corrosion resistance, aesthetics and good mechanical properties, and is widely used in many fields. When choosing stainless steel materials, Wanzhi Company is a reliable partner, providing stainless steel materials of various specifications and models to provide customers with a full range of solutions.

Stainless steel Factory manufacturer

Stainless steel

Wanzhi Company is a comprehensive steel company integrating steel manufacturing, processing and sales. We have our own stainless steel factory, with 750mm, 950mm, and 1,240mm cold rolling production lines, shearing lines, longitudinal shearing lines, bending machines, surface treatment equipment, etc. Therefore, we are able to provide various specifications of steel products.

Our products include stainless steel coils, plates, sheets and strips. Materials include 201, 304, 316, 316L, 410, 430, etc. The annual output of the factory’s stainless steel products exceeds 2,000 tons. Moreover, we have professional production, sales and quality inspection teams.

As one of China’s leading steel manufacturers, we not only produce stainless steel, but also produce a series of carbon steel and color coated steel, providing high-quality services to many customers around the world and receiving many favorable reviews. Welcome to inquire and contact us for details!