Welded Steel Pipe

What is a Welded Steel Pipe?

Welded steel pipe, also known as welded pipe, is a steel pipe made by welding steel plates or steel strips after curling and forming. The production process of welded steel pipe is simple, the production efficiency is high, the varieties and specifications are many, and the equipment investment is small, but the general strength is lower than that of seamless steel pipe.

Since the 1930s, with the rapid development of high-quality strip steel continuous rolling production and the advancement of welding and inspection technology, the quality of welds has been continuously improved, the varieties and specifications of welded steel pipes have increased, and they have replaced seamless steel pipes in more and more fields.

Classification of welded steel pipe

According to the form of welds

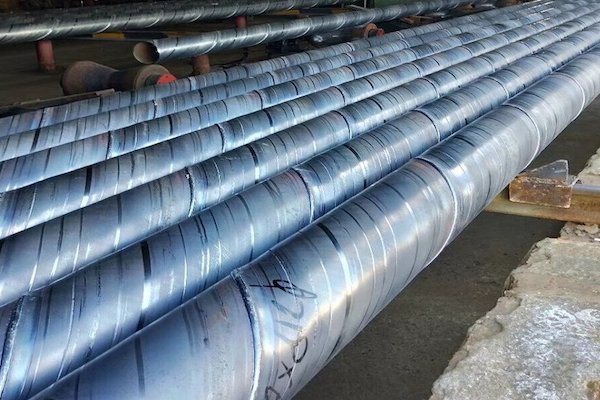

Welded steel pipes are divided into straight seam welded pipes and spiral welded pipes according to the form of the weld.

The production process of straight seam welded pipes is simple, the production efficiency is high, the cost is low, and the development is rapid.

The strength of spiral welded pipes is generally higher than that of straight seam welded pipes. Narrower billets can be used to produce welded pipes with larger diameters, and billets of the same width can also be used to produce welded pipes with different diameters. However, compared with straight seam pipes of the same length, the weld length increases by 30~100%, and the production speed is relatively lower than that of straight seam welded pipes.

Threaded welded pipe

Straight seam welded pipe

Therefore, smaller diameter welded pipes mostly use straight seam welding, while large diameter welded pipes mostly use spiral welding.

Classification by welding method

It can be divided into: arc welded pipe, (high frequency, low frequency) resistance welded pipe, gas welded pipe, furnace welded pipe, submerged arc welded pipe, downward welded pipe.

Steel pipe end shape

According to the shape, it is divided into round welded pipe and special-shaped (square, rectangular, triangular, diamond, etc.) welded pipe;

Round welded steel pipe

Rectangular welded pipe

Differentiate by material and purpose

If it is differentiated by material and purpose, it can be divided into welded pipe for mining fluid transportation, galvanized welded pipe for low-pressure fluid transportation, belt conveyor roller electric welded pipe, etc.

Welded steel pipe for low-pressure fluid transportation is also called general welded pipe, commonly known as black pipe. It is a welded pipe used for conveying generally low-pressure fluids such as water, gas, air, oil and heating steam and other purposes. In addition to being directly used for conveying fluids, it is also widely used as the original pipe of galvanized welded pipe for low-pressure fluid transportation.

Use classification

Welded pipes can be divided into general welded pipes, galvanized welded pipes, oxygen-blown welded pipes, wire casings, metric welded pipes, roller pipes, deep well pump pipes, automobile pipes, transformer pipes, electric welded thin-walled pipes, electric welded special-shaped pipes, scaffolding pipes and spiral welded pipes according to their uses.

Specifications of commonly used welded steel pipes

| Nominal diameter | Outer diameter(mm) | Ordinary pipe | Thickened pipe | |||

| mm | in | Pipe wall thickness(mm) | Theoretical mass (Kg/m) | Pipe wall thickness(mm) | Theoretical mass (Kg/m) | |

| 6 | 1/8″ | 10.0 | 2.00 | 0.39 | 2.5 | 0.46 |

| 8 | 1/4″ | 13.5 | 2.25 | 0.62 | 2.75 | 0.73 |

| 10 | 3/8″ | 17 | 2.25 | 0.82 | 2.75 | 0.97 |

| 15 | 1/2″ | 21.25 | 2.75 | 1.26 | 3.25 | 1.45 |

| 20 | 3/4″ | 26.75 | 2.75 | 1.63 | 3.5 | 2.01 |

| 25 | 1″ | 33.5 | 3.25 | 2.42 | 4 | 2.91 |

| 32 | 1 1/4″ | 42.25 | 3.25 | 3.13 | 4 | 3.78 |

| 40 | 1 1/2″ | 48 | 3.5 | 3.84 | 4.25 | 4.58 |

| 50 | 2″ | 60 | 3.5 | 4.88 | 4.5 | 6.16 |

| 65 | 2 1/2″ | 75.5 | 3.75 | 6.64 | 4.5 | 7.88 |

| 80 | 3″ | 88.5 | 4 | 8.34 | 4.75 | 9.81 |

| 100 | 4″ | 114 | 4 | 10.85 | 5 | 13.44 |

| 125 | 5″ | 140 | 4 | 13.42 | 5.5 | 18.24 |

| 150 | 6″ | 165 | 4.5 | 17.81 | 5.5 | 21.63 |

Process flow of welded steel pipe

Raw material uncoiling – flattening – end shearing and welding – looping – forming – welding – internal and external weld bead removal – pre-correction – induction heat treatment – sizing and straightening – eddy current testing – cutting – water pressure inspection – pickling – final inspection (strict control) – packaging – shipment.

Application scope of welded steel pipe

Welded steel pipe products are widely used in tap water projects, petrochemical industry, chemical industry, power industry, agricultural irrigation, urban construction, etc.

Liquid transportation: water supply, drainage.

Gas transportation: coal gas, steam, liquefied petroleum gas.

Structural use: as piling pipes, bridges; docks, roads, building structure pipes, etc.

Special applications: furnace welded pipes can be used as water gas pipes, etc.

Foreman welding pipe

High quality welded pipe

Spiral welded pipes are often used for oil and gas transportation, pipe piles, bridge piers, etc., while straight seam welded pipes are mostly used for high-pressure oil and gas transportation, etc.

Welded Steel Pipe Manufacturers

Wanzhi was founded in 2011. After more than ten years of development, it has a mature production team, a strict inspection team, and an excellent sales team.

The products we produce include: steel pipes, steel plates, steel coils, color-coated steel, galvanized steel, corrugated steel plates, tinplates, etc. At Wanzhi, you can find the most suitable products and get the best service.

The quality of our products is trustworthy. We have a lot of long-term customers, and some purchasing customers can place orders more than ten times a year. You are welcome to inquire for detailed product information.