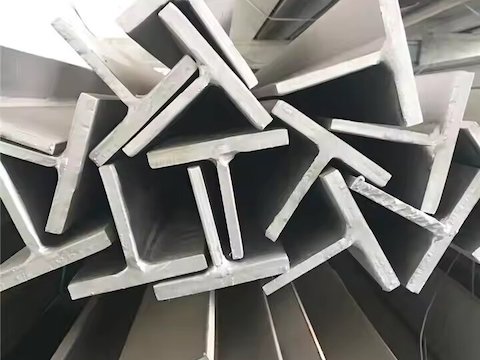

T-beam

Definition and classification of T-beam

T-beam steel is a type of steel that is cast into a T-shape, and is named because its cross section is the same as the capital letter “T”.

Specifications of T-beam

T-beam steel codes correspond to T-beam steel, wide flange T-shaped steel (TW), middle flange T-shaped steel (TM) and narrow flange T-shaped steel (TN). The representation method is generally “height H×width B×web thickness t1×flange thickness t2”, in millimeters (mm). For example, T-shaped steel Q235B or SS400 200×200×8×12, represents a T-shaped steel with a height of 200mm, a width of 200mm, a web thickness of 8mm, and a flange thickness of 12mm.

Classification

Based on the production process, there are hot-rolled T-beam, cold-drawn T-beaml, welded T-beam, split T-shaped steel, etc. Based on the use, there are curtain wall T-shaped steel, ship T-shaped steel, railway T-shaped steel, elevator T-shaped steel, cable drum T-shaped steel, etc.

Production process of T-beam steel

The production process of T-shaped steel mainly includes hot-rolled T-shaped steel, split T-shaped steel, cold-drawn T-shaped steel, welded T-shaped steel and other processes. The following is a detailed introduction to each process:

Thick T-beam steel

Thin T-shaped steel

Hot-rolled T-beam:

After the steel billet is heated, it is introduced into the steel billet for forming, and then rolled by a rolling mill. It can be formed in one go and has good stability. It is suitable for precision parts with high requirements for firmness. At present, it is limited to the production of smaller specifications of T-shaped steel, generally below 100mm×100mm.

Cold-drawn T-beam:

T-beam is produced by cold-drawing equipment to draw the steel billet into T-shaped steel. It has a smooth surface and high precision. It is often used in related accessories of elevator guide rails.

Welded T-beam:

The cross-section is made into a T shape by welding technology. The steel plate is made by a series of processes such as automatic striping, assembly, and automatic submerged arc welding, which can ensure dimensional accuracy and weld quality. There are two welding processes: high-frequency welding is used for plates with a thickness greater than 10mm, and submerged arc welding is used for plates with a thickness greater than 10mm.

Split T-beam:

This type of T-beam is produced by cutting finished H-beam. The waist height of the H-beam is split into two by automated cutting equipment such as shearing equipment, and then straightened by a straightening machine.

The production process of T-beams involves not only forming the steel, but also ensuring that the final product meets the required specifications and quality standards. Each production method has its own unique advantages and limitations, and the choice of method depends on the specific requirements of the final product.

Characteristics of T-beam steel

Superior mechanical properties:

T-beam steel stock

Cold Rolled T-shaped steel

T-shaped steel has high bending strength and load-bearing capacity. It’s special cross-sectional shape and high bending section modulus can effectively resist external loads and are suitable for engineering structures and machinery manufacturing that bear large loads. And it’s wing plate is wide, providing greater torsional stiffness and can withstand greater torque.

Good stability:

The special cross-sectional shape of T-shaped steel gives it good stability, can resist the effects of natural forces such as wind and snow, and ensure the safety and stability of engineering structures.

Convenient processing:

It’s manufacturing process is relatively simple, and it can be produced by hot rolling, cold bending, welding and other processes. It can also be processed by cutting, drilling and other methods. It is suitable for various structural design and construction needs, with high production efficiency and low cost.

Light weight:

Compared with traditional I-beams or rectangular cross-sectional steels, T-shaped steels are lighter while maintaining the same strength, reducing transportation and installation costs.

Save materials:

The design makes full use of the mechanical properties of the material, reduces unnecessary material use, and improves resource utilization efficiency.

Application of T-beam steel

T-shaped steel is widely used in many fields due to its unique cross-sectional shape and excellent performance.

Q195 T-beam steel

Q235 T-shaped steel

Construction field:

T-shaped steel is often used as load-bearing structural components such as beams, columns, ladder frames, etc. In high-rise buildings, large factories, gymnasiums and other buildings, it can be used to make frame structures and support systems. Because of its high strength and high rigidity, it can effectively support and transfer loads to ensure the stability and safety of the building structure. It can also be used for stair handrails, guardrails and protective facilities.

Bridge field:

T-shaped steel is often used in the main beams and support columns in bridge structures. It can withstand large loads and deformations to ensure the stability of the bridge structure.

The T-beam steel can also be used to make bridge piers and bridge decks to resist erosion by strong winds and heavy rains.

Mechanical manufacturing:

T-shaped steel can be used to manufacture key components such as bases and support frames of mechanical equipment to meet the requirements of mechanical equipment for stability and precision. It’s also used to manufacture parts of mechanical equipment, such as bearings, gears, racks, etc. Its excellent mechanical properties and durability can meet complex work requirements.

Vehicle manufacturing field:

It can be used in the production of structures such as frames and carriages to improve the safety and comfort of automobiles.

Shipbuilding:

Used in load-bearing structures such as beams and longitudinal beams in the hull structure, providing strong support for the safe operation of ships.

Power facilities:

T-shaped steel is often used to make transmission towers, substation brackets, etc., to ensure the stability and safety of power facilities.

Cold Drawn T-beam steel

Cutting T-beam steel

Other fields:

It can also be used to manufacture furniture, shelves, etc. It is also widely used in the fields of oil and gas extraction, petrochemicals, etc. in the energy industry. Such as for the manufacture of natural gas pipelines, oil storage tanks and refining equipment.

Common specifications of T-beam steel

T-shaped steel has a wide range of specifications. Common hot-rolled T-shaped steel specifications (unit: mm) are classified as follows:

50×100×6×8 to 194×402×15×15

62.5×125×6.5×9 to 195×300×10×16

74×100×6×9 to 75×150×7×10

Notes

When selecting T-shaped steel, you should choose according to the specific project requirements and the use environment to ensure that the selected specifications and models of T-shaped steel can meet the design requirements and service life.

During use, you should pay attention to the storage and transportation of T-shaped steel to avoid moisture, corrosion and damage to ensure its quality and performance.