The corrosion resistance of aluminum zinc coated coils (such as 55% aluminum zinc alloy, commonly known as Galvalume) is superior to that of ordinary galvanized coils (pure zinc coating) in most environments, but not all environments are suitable. Its advantages and limitations need to be analyzed in conjunction with specific corrosion conditions.

Comparison of Corrosion Resistance with Galvalume vs Galvanized

| Environment Type | Aluminum Zinc (AZ/GL) | Galvanized (GI) performance | Заключение |

| Neutral/alkaline atmosphere | The oxide film of aluminum (Al ₂ O3) is dense and stable, with excellent corrosion resistance | Sacrificial protection of zinc layer, but faster corrosion rate | AZ is significantly better than GI |

| Weak acid environment (pH 4-6) | Aluminum film partial protection, zinc component assisted sacrificial anode | Zinc dissolves quickly and has a short lifespan | AZ is superior to GI |

| Strong acid environment (pH<3) | Aluminum film ruptures, zinc accelerates corrosion, and ultimately fails | Zinc reacts violently and is rapidly consumed | Both are not applicable and require stainless steel or coating |

| High chlorine environment (coastal) | Aluminum film is resistant to chloride ion corrosion and has a long lifespan | Zinc is susceptible to chloride ion corrosion, resulting in white rust/red rust | AZ is superior to GI |

| High temperature and high humidity (industrial area) | Aluminum zinc synergistic effect delays corrosion | The zinc layer is consumed quickly, and the substrate is easily exposed | AZ is superior to GI |

| Alkaline environment (pH>9) | Aluminum film dissolution accelerates zinc corrosion | Zinc is relatively stable under alkaline conditions | GI is superior to AZ |

Limitations of Galvalume

I. Alkaline environment (such as contact with concrete)

Aluminum will dissolve at pH>9, causing the corrosion rate of aluminum zinc coated sheets to exceed that of galvanized sheets in concrete pouring or alkaline soil.

At this time, galvanized sheet or an additional isolation layer (such as epoxy coating) should be used.

II. Cutting edges/scratched areas

The sacrificial protection of aluminum zinc plating (zinc) is limited to local areas, and edge corrosion may be more pronounced than that of galvanized sheets (the sacrificial anode effect of galvanizing is more comprehensive).

III. Condensed water environment (such as roof)

Acidic condensate (industrial waste gas) may cause pitting corrosion of aluminum zinc plating, while galvanized sheet exhibits uniform corrosion.

Galvalume vs Galvanized reference data

| Test conditions | Galvanized (Z275) Red Rust Time | Aluminum zinc (AZ150) Red rust time |

| Neutral salt spray (ASTM B117) | 500~800 hours | 1000~1500 hours |

| Acid salt spray (pH=3) | 200~400 hours | 600~800 hours |

| Ocean atmosphere (outdoor exposure) | 5-10 years | 15-25 years |

Material selection suggestions – Application environment

The advantages of aluminum zinc coated steel

Stronger corrosion resistance – In coastal, industrial areas, and high humidity environments, the aluminum oxide film (Al ₂ O3) provides stronger protection and typically has a lifespan 2-6 times longer than galvanized steel.

Better high-temperature resistance – suitable for high-temperature environments such as roofs and high-temperature exhaust components.

Better economy (long-term) – Aluminum zinc coated steel has lower long-term maintenance costs in corrosive environments.

Application environment:

Coastal areas, industrial pollution areas, weak acid rain areas, and high temperature and high humidity climates.

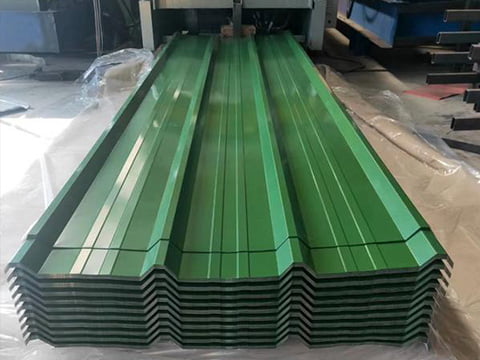

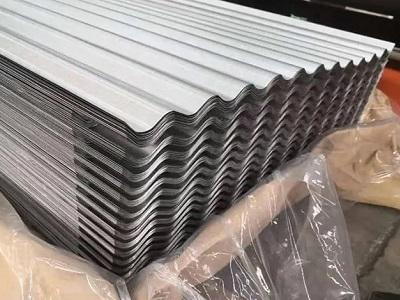

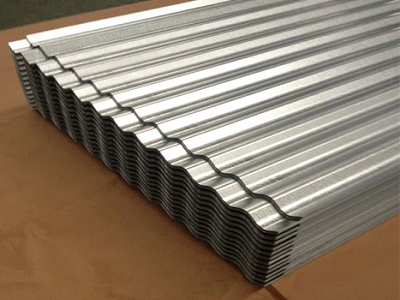

Typical applications: Color coated substrates, roofs/exterior walls, automotive exhaust pipes (external).

Advantages of galvanized steel

Alkali resistant environment (pH>9) – Galvanized steel is more corrosion-resistant in contact with concrete or highly alkaline soil (such as building steel bars, underground pipelines).

Better incision protection – The pure zinc layer of galvanized steel provides more comprehensive sacrificial protection for cutting and welding parts (suitable for parts that need to be processed).

Lower cost (short-term) – Galvanized steel has lower initial costs in dry or weakly corrosive environments.

Application environment:

Cutting parts that require comprehensive sacrifice protection in alkaline environments (contact with concrete).

Typical applications: steel reinforcement brackets, underground pipelines (requiring coating).

An environment where neither is applicable

Strong acid/strong alkali, high salt and high temperature (such as chemical plants): Use stainless steel, nickel based alloys or organic coated steel plates instead.

Краткое содержание

Aluminum zinc coated steel coils have better corrosion resistance than galvanized steel sheets in most natural and industrial environments, but may perform even worse in alkaline environments, localized damage, or extreme chemical conditions. The selection should be based on specific environmental parameters, cost, and lifespan requirements, and if necessary, verified through salt spray testing or on-site hanging.

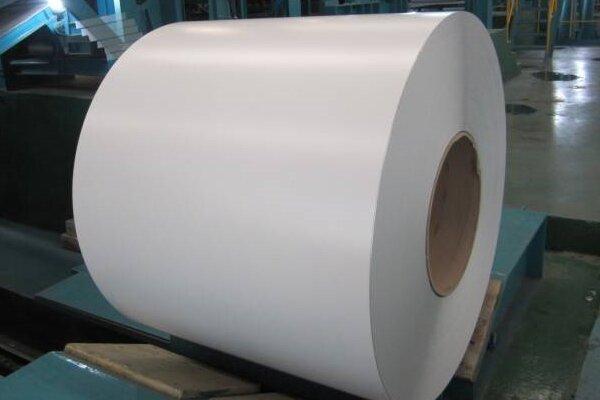

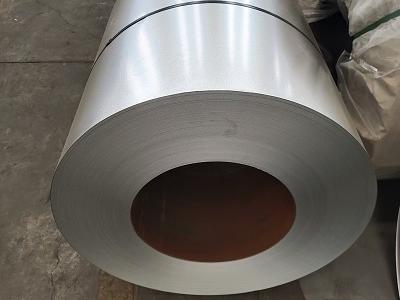

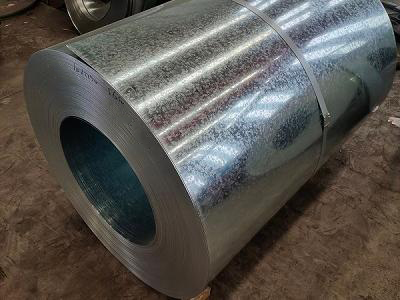

Wanzhi Steel exports a large amount of galvanized steel coils and aluminum zinc coated steel coils every year. We have a professional team and a complete production line, which can provide professional services and high-quality products for every customer. Welcome to inquire and place orders.