Angle Steel

What Is Angle Steel?

Angle steel, commonly known as angle iron, is a special steel material used to support and fix structures. Its cross-section is L-shaped, so it is also called L-shaped angle steel. Angle steel is a long steel strip with two sides perpendicular to each other. There are equal-leg angle steel and unequal-leg angle steel.

Angle steel is usually made of carbon steel, alloy steel or stainless steel, with certain strength and rigidity, and is widely used in construction, machinery manufacturing, bridges, ships and other fields.

Galvanized Angle Steel

Stainless Steel Angle

Angle steel attributes

| Элемент | Параметры продукта |

| Название продукта | Angle steel |

| Common Material | Q195-Q420 Series |

| Material Type | Low carbon steel/Stainless steel |

| Тип | Equal,Unequal |

| length | 2-12m |

| Толщина | 3-24mm |

| Model | 2# – 20# |

| приложение | Building structures, other industrial structures and fixed cabinets |

| Стандартный | ISO/JIS/GB/ASTM/DIN |

| Минимальный объем заказа | 10tons |

| Supply Ability | 5000 tons per month |

| Payment term | L/C T/T (30% Deposit) |

| Упаковка | Стандартный экспортный пакет |

How to melt Angle Steel?

Angle steel is often used to make building structures, mechanical equipment, and other industrial purposes. It is usually made by mixing smelting steel and iron ore.

1.Raw material preparation: To make angle steel, you first need to prepare raw materials, including steel and iron ore. Steel is the main raw material for smelting angle steel, while iron ore is the source of iron.

2.Melting furnace: Put the prepared steel and iron ore into the smelting furnace. The smelting furnace is usually a high temperature and high pressure environment, which is used to heat the raw materials to the melting point and mix them together.

3.Adding alloys: During the smelting process, it is usually necessary to add some alloys to the smelting furnace. These alloys can change the properties of steel and make it more suitable for specific applications. Commonly used alloys include nickel, chromium, manganese, and vanadium.

4.Casting: Once the raw materials and alloys are fully mixed, casting can begin. At this stage, the molten metal is poured into the mold and allowed to cool and solidify.

5.Heat treatment and tempering: In order to improve the hardness and strength of angle steel, heat treatment and tempering are usually required. These processes include heating, cooling and solution treatment.

6.Surface treatment: Finally, the angle steel may need some surface treatment, such as rust removal, painting and coating.

In general, melting angle steel is a complex process that requires strict control and treatment to produce high-quality steel.

Theoretical weight of equal angle steel

| Model | Стандартный(mm) | Theory(kg/m) | Model | Стандартный(mm) | Theory(kg/m) |

| 2.5# | 25*3 | 1.124 | 7# | 70*6 | 6.406 |

| 25*4 | 1.459 | 70*7 | 7.398 | ||

| 3# | 30*3 | 1.373 | 70*8 | 8.373 | |

| 30*4 | 1.786 | 7.5# | 75*5 | 5.818 | |

| 4# | 40*3 | 1.852 | 75*6 | 6.905 | |

| 40*4 | 2.422 | 75*7 | 7.976 | ||

| 40*5 | 2.976 | 75*8 | 9.030 | ||

| 5# | 50*4 | 3.059 | 75*10 | 11.089 | |

| 50*5 | 3.770 | 8# | 80*6 | 7.376 | |

| 50*6 | 4.465 | 80*8 | 9.658 | ||

| 6.3# | 63*5 | 4.822 | 80*10 | 11.874 | |

| 63*6 | 5.721 | 9# | 90*6 | 8.350 | |

| 63*8 | 7.469 | 90*7 | 9.656 | ||

| 7# | 70*5 | 5.397 | 90*8 | 10.946 |

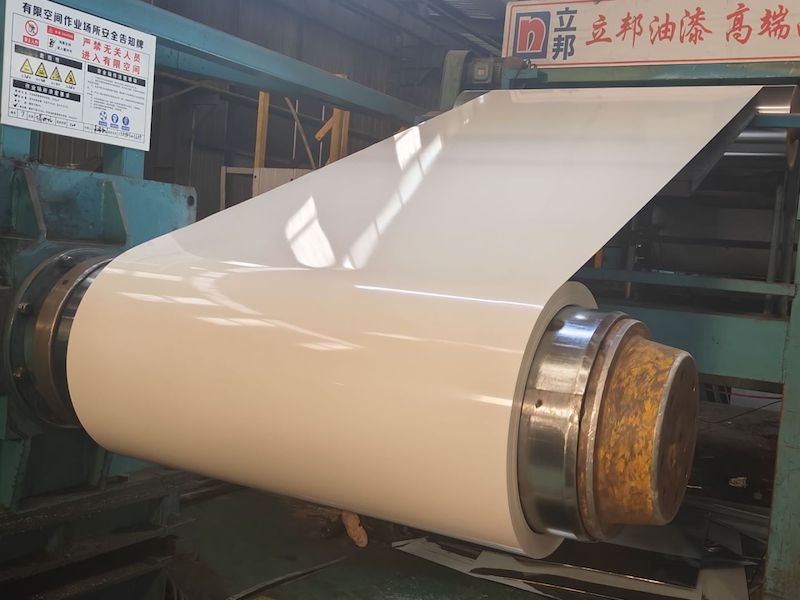

Angle steel can be divided into equal-leg angle steel и unequal-leg angle steel.

Equal angle steel

Unequal angle steel

The two sides of equal-leg angle steel are equal in width. Its specifications are expressed in millimeters of side width × side width × side thickness. For example, “∟30×30×3” means an equal-leg angle steel with a side width of 30 mm and a side thickness of 3 mm. It can also be expressed by model, which is the number of centimeters of the side width, such as ∟3#.

The model does not indicate the size of different side thicknesses in the same model, so the side width and side thickness of the angle steel should be filled in completely on the contract and other documents to avoid using the model alone. The specifications of hot-rolled equal-leg angle steel are 2#-20#.

Angle steel classification

Angle steel is a metal component with different classifications, which is widely used in construction, machinery manufacturing, automobile manufacturing and other fields. According to different standards and uses, angle steel can be divided into many different classifications.

Classification by material

According to different materials, angle steel can be divided into carbon steel angle steel, alloy steel angle steel, stainless steel angle steel, etc. Carbon steel angle steel is mainly composed of carbon elements and a small amount of other alloy elements. It has high strength and hardness and is widely used in construction, machinery manufacturing and other fields. Alloy steel angle steel usually adds certain alloy elements, such as chromium, manganese, molybdenum, etc. to improve its mechanical properties and wear resistance. Stainless steel angle steel is mainly composed of chromium, nickel and other elements. It has corrosion resistance and is often used in chemical industry, shipbuilding and other fields.

Classification by shape

According to the cross-sectional shape of angle steel, it can be divided into equal angle steel, unequal angle steel, flat steel, center angle steel, etc. The two sides of equal angle steel are equal in length and are often used in structures with low strength requirements. The two sides of unequal angle steel are unequal in length and can be selected according to actual needs. Flat steel is a kind of angle steel with a rectangular cross section, which is mainly used to manufacture mechanical parts, tools and cold bending. The cross section of the center angle steel is convex, which is suitable for structures that need to withstand large bending forces.

Classification by specification

According to the specifications and sizes of angle steel, it can be divided into standard angle steel and non-standard angle steel. The specifications of standard angle steel meet national or industry standards and are often used in general structural engineering. Non-standard angle steel is suitable for some special engineering needs, and its specifications and sizes can be customized according to customer requirements.

According to processing technology

According to different processing technologies, angle steel can be divided into hot-rolled angle steel and cold-drawn angle steel. Hot-rolled angle steel is formed by hot rolling process at high temperature, with a rough surface, and is often used in large-scale structural engineering. Cold-drawn angle steel is formed by cold processing process, with a smooth surface and precise size, which is suitable for precision machinery manufacturing and bicycles, motorcycles and other fields.

Factory stock

Hot rolled steel angle

In general, the classification of angle steel is diverse, and can be classified according to different factors such as material, shape, specification and processing technology. These classifications can help users choose the most suitable angle steel products according to actual needs to meet the needs of engineering and manufacturing.

Application of Angle Steel

Angle steel is a metal material processed by hot rolling, cold bending or welding, usually with an L-shaped cross-section. It has many uses and is therefore widely used in construction, manufacturing and other industries.

Building structure

Angle steel is often used for support and connection in building structures. It can be used as stair handrails, stair steps, platform edge protection, ceiling support, wall corner protection, etc. In building structures, angle steel can also be used as components of frames and supporting structures, such as frame connectors, beam connectors and column connectors.

Vehicle manufacturing

Angle steel is also widely used in automobile and other vehicle manufacturing. It can be used for vehicle chassis, frames, bodies and other structural components. In vehicle manufacturing, angle steel is often used as structural support and connectors to enhance the stability and strength of the vehicle.

Machinery manufacturing

Angle steel is also a common material in machinery manufacturing and processing. It can be used as a support, connection and fixing component of mechanical equipment, such as machine tool bed, machine tool column, workbench bracket, etc. Angle steel can also be used to manufacture auxiliary equipment such as shelves, workbenches, fixtures, etc.

Furniture manufacturing

Angle steel also has certain uses in furniture manufacturing. It can be used as a supporting and connecting component of furniture, such as the legs of a table, the armrests of a chair, the fixed structure of a cabinet, etc.

Shipbuilding

In the field of shipbuilding, angle steel is often used as a supporting and connecting component for hull structures and ship equipment. It can be used to make deck supports, hull frames, cabin bulkheads, etc.

Steel structure engineering

In steel structure engineering, angle steel is one of the common components. It can be used to make components such as steel structure frames, steel structure beams and columns, steel structure beams and plates to support and connect the entire structural system.

Alloy steel angle

Low carbon steel angle

In general, angle steel has a variety of uses and can be used in various fields such as construction, manufacturing, transportation, machinery manufacturing, furniture manufacturing, shipbuilding, steel structure engineering, etc. Its strength and stability make it an ideal structural material that plays an important role in different fields.

Angle steel price

The calculation of angle steel price is determined by different factors, including material cost, processing cost, market demand and supply conditions.

Material cost

The price of angle steel depends first on its material cost, including the purchase cost, processing and production cost of raw materials. Common materials for angle steel include ordinary carbon structural steel, alloy structural steel, stainless steel, etc. Different materials have different costs, which will directly affect the price of angle steel.

Processing cost

During the production process, angle steel needs to undergo cutting, bending, welding, heat treatment and other processing processes. These processing costs will also directly affect the price of angle steel. Generally speaking, the more complex the processing and the more stringent the process requirements, the higher the price of angle steel.

Market demand and supply conditions

Market demand and supply conditions are one of the important factors affecting prices. If the market demand is large and the supply is relatively small, the price of angle steel will be relatively high; on the contrary, if the market supply is sufficient and the demand is relatively small, the price will be lower.

Angle steel manufacturers

Wanzhi Steel is a professional producer of angle steel. It is equipped with advanced production equipment and strict quality control systems. Wanzhi Steel focuses on innovation and continuously improves its production technology to ensure the high quality and excellent performance of its angle steel products.With reliable quality and good service, Wanzhi Steel has established a solid reputation in the market and is committed to providing the best angle steel solutions.