Galvanized Steel Pipe

Length: 4-12m or customizable

Thickness: 1.6 – 4.5mm

Standard: GB/T 3091-2015

Product Introduce

Galvanized steel pipe is a core material in today’s construction, industry and infrastructure fields. Its unique anti-corrosion properties and high mechanical strength make it a revolutionary alternative to traditional steel pipes. Through the hot-dip galvanizing process, a dense zinc-iron alloy layer is formed on the surface of the steel pipe, which increases the corrosion resistance by 3-5 times and has a service life of more than 50 years.

Core performance advantages

Weather resistance: The zinc layer isolates air moisture and effectively resists atmospheric corrosion, soil corrosion and chemical medium corrosion.

Maintenance-free: The self-healing properties of zinc (sacrificial anode protection) can repair tiny scratches.

Economical: The purchase cost is lower than stainless steel, and the maintenance cost is lower than ordinary carbon steel pipes.

Product Parameters

| Item | Parameters |

| Products name | Galvanized Steel Pipe |

| Thickness | 0.25-100 mm |

| Outside diameter | 20-220 mm |

| Length | 4~12m, customer requirements |

| Application | Construction, bridges, roads and tunnels, machinery manufacturing, aerospace, military industry, automobiles, etc. |

| MOQ | 10 tons |

| Delivery time | 15-21 days for conventional products, negotiated for customized products |

| Payment Term | T/T,100% L/C at sight |

| Packing | Standard freight packaging |

Size specification parameter table

| Nominal diameter | Inches | Outer diameter (mm) | Wall thickness (mm) | Theoretical weight (kg/m) | Implementation standard |

| DN15 | 1/2″ | 21.3 | 2.75~2.8 | 1.28~1.357 | GB/T 3091 |

| DN20 | 3/4″ | 26.9 | 2.75~2.8 | 1.66~1.76 | |

| DN25 | 1″ | 33.7 | 3.2 | 2.41~2.554 | |

| DN50 | 2″ | 60.3 | 3.5~3.8 | 5.29~5.607 | |

| DN100 | 4″ | 114.3 | 4.0 | 10.88~11.53 | |

| DN200 | 8″ | 219.1 | 6.0 (minimum) | 31.53 (estimated) |

Application scenarios

Building structure field

High-rise building skeleton: galvanized steel pipe as SC structural column

Scaffolding system: quick-detachable galvanized steel pipe scaffolding

Roof drainage system: K-shaped/semicircular downpipe

Industrial and municipal engineering

Fire protection pipe network: NFPA-compliant, with grooved fittings for quick connection

Water supply and delivery system: replace cast iron pipes, reducing 80% scale accumulation

Solar support: C-type/Z-type galvanized support (salt spray test > 1000 hours)

Emerging application scenarios

Modular building: prefabricated galvanized steel pipe frame

Vertical farm: thin-walled precision pipe fittings (Φ25mm-50mm) nutrient solution delivery system

Electric vehicle battery rack: high-strength galvanized square tube (impact strength ≥ 500MPa)

FAQ about Galvanized Steel Pipes

Q: What is the lifespan of galvanized steel pipes in seawater environments?

A: >50 years in conventional environments, about 20-30 years within 500 meters of the coast (it is recommended to use zinc-aluminum-magnesium coating to increase to 40 years).

Q: How to identify inferior galvanized pipes?

A: Three-view rule: look at the surface (uniformity of zinc flowers), look at the incision (no black slag), and look at the certificate.

Q: Precautions for welding galvanized pipes?

A: The welding area must be polished in advance and low-hydrogen electrodes (such as E7018) must be used. Zinc-rich paint (zinc content ≥92%) must be applied after welding.

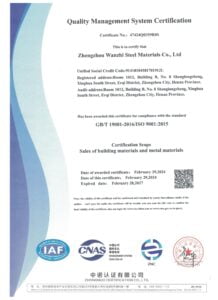

Quality Certificate Show

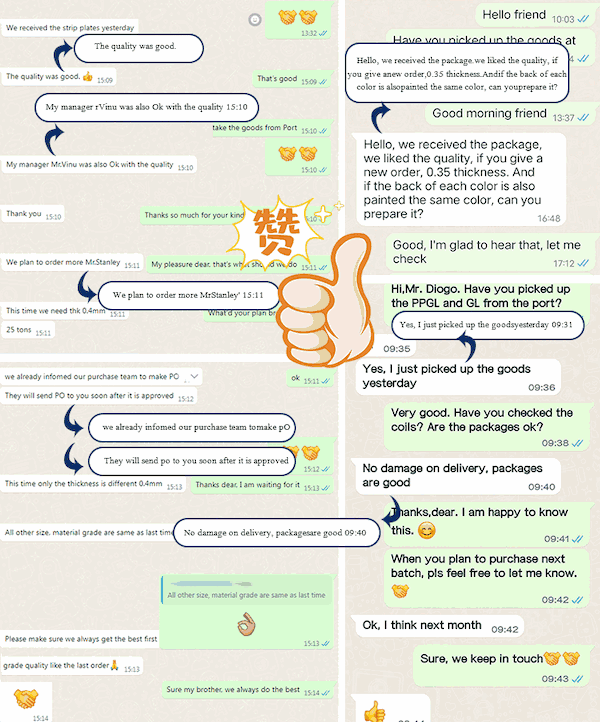

Customer affirmation

Why choose us?

Companies with high trade rankings in the steel industry.

Customized steel processing one-stop procurement.

Steel exports have exceeded 200 million for five consecutive years.

We have a complete set of testing equipment, such as UV aging chamber, salt spray testing machine, universal testing machine, Rockwell hardness tester, electroplating thickness tester, T-bending testing machine, etc., and have passed SGS TUV certification.

Contact us

Company: Erqi District, Zhengzhou City, Henan Province, China

Factory: Binzhou City, Shandong Province, ChinaList item

E-mail: info04@wanzhisteel.com

WhatsApp: +86 18736065220

Website: https://wanzhisteels.com

Hot Tags: Galvanized Steel Pipe, Galvanized Pipe, Schedule 40 Galvanized Pipe, Corrosion-Resistant Water Pipe, Scaffolding Galvanized Pipe, manufacturers, suppliers, factory, low price, for sale