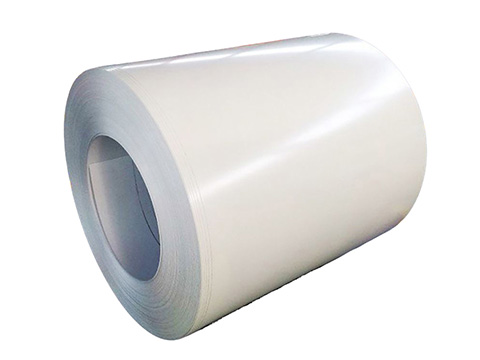

0.5mm PPGI Roofing Sheets

Color: RAL Color or Customization

Standard: ASTM, JIS, AISI, ASTM, GB, EN

Length: 1-12m or customer’s requirement

Product Introduce

0.5mm PPGI Roofing Sheets are durable, weather-resistant, and feature a color-coated protective coating. Their combination of strength, corrosion resistance, and aesthetics makes them an ideal choice for industrial, commercial, and residential construction. They offer long-lasting durability and low maintenance in a variety of environmental conditions.

Product Specifications

| Item | Parameters |

| Products name | 0.5mm PPGI Roofing sheet |

| Standard | ASTM, JIS, AISI, ASTM, GB, DIN, EN |

| Base material type | Cold rolled steel (such as DX51D, SGCC), hot rolled steel (such as Q235B) |

| Color coating | Customizable RAL color (such as deep sea blue RAL 5010, sandstone yellow RAL 1002) |

| Thickness | 0.5 mm |

| Width | 750–1250mm (before corrugation) / 665–1100mm (after corrugation) |

| Length | 1-12m, According to customer requirements |

| MOQ | 10 tons |

| Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

| Delivery Time | 20-35 work days |

| Payment Term | T/T, L/C at sight |

| Transport Package | Standard Seaworthy Packing |

Thickness comparison

| Dimensions | Traditional thin panels (0.3-0.4mm) | 0.5mm thick panels | Thick panels (≥0.6mm) |

| Cost | Low (base price) | +10% ~ 15% | +30% ~ 50% |

| Lifespan | 5 ~ 8 years | 10 ~ 15 years ( normal use ) | 15 ~ 25 years |

| Wind load resistance | <1.0kPa (easily deformed) | ≥1.2kPa (resistant to force 12 winds) | ≥1.8kPa |

| Snow load resistance | <0.6kN/m² | ≥0.8kN/m² (suitable for moderate snow areas) | ≥1.2kN/m² |

| Maintenance frequency | 5 years for inspection | 8 ~ 10 years for the first maintenance | 12 years and above |

Summary: 0.5mm PPGI Roofing Sheets is achieve the optimal balance between cost and life in 90% of civil and industrial scenarios.

Recommended application scenarios

| Scenarios | Recommendation | Coating Solutions |

| Industrial Plants (Lightweight) | Bearing equipment vibration and moderate snow loads (0.8 kN/m²), the preferred choice for cost-sensitive projects. | SMP Coating (120 g/m² zinc layer) |

| Commercial Buildings (Supermarkets/Exhibition Halls) | Long-span roofs (1.5 m purlin spacing), requiring a highly flat appearance. | HDP Coating (150 g/m² zinc layer) |

| Agricultural Greenhouses | Resistant to agrochemicals while ensuring consistent light transmission. | PE Coating + Chemical Resistance Treatment |

| Residential Buildings in Rainy Areas | Resistant to frequent rain erosion, with a drainage slope ≥ 10% and a longer lifespan than thin panels. | PVDF Coating (180 g/m² zinc layer) |

| Photovoltaic Roof Substrates | Rigid support for solar panel mounting (static load ≥ 15 kg/m²). Insufficient thickness can easily cause micro-deformation and leaks. | HDP/PVDF + Insulating Back Coating |

Application Scenarios

Industrial and Commercial Buildings

Roofs/Walls: Suitable for factories, warehouses, and logistics centers. A 0.5mm thickness balances cost and wind resistance.

Insulation Requirements: High reflectivity makes it particularly suitable for high-temperature workshops or areas with intense sunlight.

Public and Agricultural Facilities

Stadiums and Farmers’ Markets: Large-span arched roofs (up to 20m) require no additional support.

Agricultural Buildings: Corrosion-resistant roofs for greenhouses and livestock sheds, with a lifespan exceeding 25 years.

Civil and Lightweight Buildings

Residential Garages/Awnings: Lightweight and suitable for retrofitting onto existing structures. Customizable colors are available (e.g., RAL 9016 Pure White, RAL 8004 Clay Red).

Temporary Facilities: Construction site sheds and emergency shelters, quickly installed and recyclable.

Production Video

Factory Production Line Display

Our Certification

Why choose us ?

We are an integrated industrial and trade company that can produce steel independently and reduce costs.

From raw materials to finished products, we control quality throughout the process to ensure that the products meet customer requirements.

The combination of production and sales confidentiality can respond to orders quickly and shorten delivery time.

One-stop service, from consultation to production, and finally to after-sales service, provides all-round support.

We are self-produced, reducing dependence on external price fluctuations. In the face of sudden price increases, we can still deliver quickly and on time.

For inventory steel, we can provide preferential prices.

FAQ

Q: Can you provide samples?

A: Yes. We can provide samples.

Q: What product information do I need to provide?

A: Please provide your base material grade, width, thickness, surface treatment requirements, and purchase quantity.

Q: What are your shipping ports?

A: We ship from Tianjin and Qingdao ports. You can specify other ports as needed.

Q: What are your payment terms?

A: 30% T/T in advance, 70% balance before shipment, and 100% L/C before shipment.

Q: Do you offer custom product services?

A: We can produce according to your specifications, drawings, and samples.

Q: What certifications do your products have?

A: We have ISO 9001 and MTC certifications, and we offer third-party inspection services such as SGS and BV.

Q: What is your delivery time?

A: Delivery time is 20-35 days. The specific time depends on the production difficulty of the product and the purchase quantity.

Q: Can I visit your factory?

A: Of course, we welcome customers from all over the world to visit our factory.

Q: Are our products quality-inspected before shipment?

A: Of course, all our products undergo rigorous quality inspection before packaging. Customers can also entrust a third party to conduct inspections before shipment.

Hot Tags: ral5015 PPGI roofing steel sheet, ral1002 PPGI Corrugated Sheet, manufacturers, suppliers, factory price, for sale, 0.5mm PPGI roofing sheets