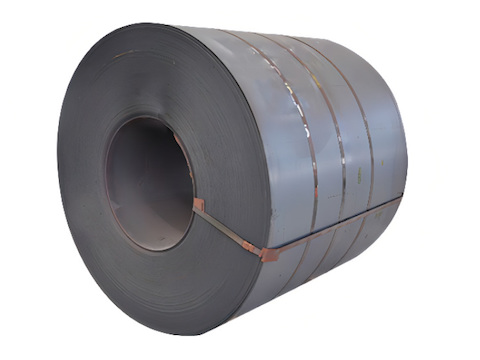

Low Carbon Steel

Width: 600-1500mm or customizable

Thickness: 0.13-4.0mm

Carbon content: 0.05%–0.30%

Product Introduce

Low carbon steel refers to an iron-carbon alloy with a carbon content (C) ranging from 0.05% to 0.25% (some standards extend to ≤0.25% or ≤0.5%). Its microstructure is mainly ferrite and contains a small amount of pearlite. Due to its low carbon content, it is also called mild steel. It is the category with the best plasticity and lowest hardness in the carbon steel family.

Its core elements include

Iron (Fe): ≥85%

Manganese (Mn): 0.10%–2.20% (to improve strength and processability)

Silicon (Si): 0.17%–0.37% (deoxidizer)

Impurity control: Sulfur (S) ≤0.050%, Phosphorus (P) ≤0.040% (to reduce brittleness)

Product Parameters

| Item | Parameters |

| Products name | Low Carbon Steel |

| Standard Specifications | ASTM, JIS, GB, EN, etc. |

| Common grades | Q195\Q235A/B\Q275\A36\S235JR\SS400\SPHC etc. |

| Widt | 600–1500 mm (customizable) |

| Length | Customized according to customer requirements |

| Processing services | Support cutting, welding, punching, bending, unwinding, etc. |

| Certification | ISO 9001, CE, SGS, etc. |

| Coil weight | 3-8 tons, customizable |

| MOQ | 10 tons |

| Delivery time | 5-14 days for conventional products, negotiated for customized products |

| Payment Term | T/T,100% L/C at sight |

| Packing | Standard seaworthy wooden box or steel strapping |

Core characteristics of low carbon steel

Excellent formability and ductility: Compared with high carbon steel, low carbon steel has extremely high ductility and plasticity.

Excellent welding performance: Low carbon steel is the type with the best welding performance among all carbon steels.

King of cost-effectiveness: Simple composition (mainly composed of iron, low carbon, manganese and a small amount of silicon), mature production process.

Good machinability: Although not as easy to cut as lead steel, the overall machinability is good and can be efficiently processed by conventional turning, milling, drilling and other means.

Moderate strength and hardness: Its strength and hardness are relatively low among carbon steels (mainly through cold working hardening can be moderately improved).

Advantages of Mild Steel

Friendly welding process: Almost all common welding methods (arc welding, MIG/MAG welding, resistance welding) are applicable.

First choice for forming processing: Take full advantage of its cold forming advantages for bending, stamping, rolling, etc.

Diverse surface treatment: Effectively improve its corrosion resistance through processes such as galvanizing, painting, powder coating, etc.

Limited heat treatment: Mainly annealing to eliminate cold working stress or improve machinability, and carburizing/carbonitriding treatment of the surface to obtain high hardness and wear resistance.

High recycling rate: Steel is one of the most recycled materials in the world. Low carbon steel is easy and efficient to recycle, significantly reducing the environmental footprint.

Application areas of low carbon steel

Construction and Infrastructure: Rebars, I-beams, angles, sheet piles – the soul of skyscrapers, bridges, roads.

Automotive: Covering body panels, chassis components, non-critical structural parts, taking into account lightweight and cost control.

Industrial Pipes and Containers: Water pipes, gas pipes, storage tanks, boiler shells (low pressure), etc., reliably transport liquids and gases.

Daily Life: From metal furniture, filing cabinets, tool housings, to fasteners such as wire, nails, and bolts, they can be seen everywhere.

Mechanical Equipment: Widely used in the manufacture of gears (low load), shafts (non-critical), racks, housings, and other parts that require good processability and a certain strength.

Our Certificates

Customer Reviews

Why choose us ?

We are an integrated industrial and trade company that can produce steel independently and reduce costs.

From raw materials to finished products, we control quality throughout the process to ensure that the products meet customer requirements.

The combination of production and sales confidentiality can respond to orders quickly and shorten delivery time.

One-stop service, from consultation to production, and finally to after-sales service, provides all-round support.

We are self-produced, reducing dependence on external price fluctuations. In the face of sudden price increases, we can still deliver quickly and on time.

For inventory steel, we can provide preferential prices.

Contact us

Factory: Binzhou City, Shandong Province, ChinaList item

Company: Erqi District, Zhengzhou City, Henan Province, China

E-mail: info04@wanzhisteel.com

WhatsApp: +86 18736065220

Hot Tags: Mild Steel Properties, Low C Steel, ASTM A36 Steel, Q235 Steel, Low Carbon Steel Applications, Welding Mild Steel, Carbon Steel Grades, Steel Forming Processes