PPGL Steel

What is PPGL Steel ?

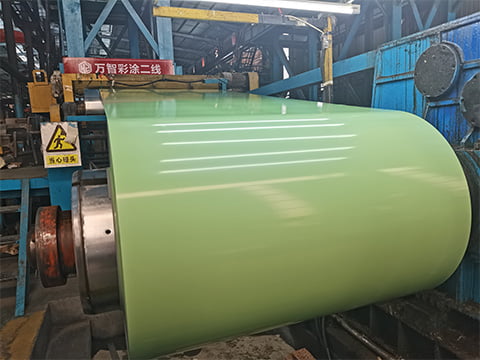

PPGL steel is a durable, brightly colored and economical building material. It is the abbreviation of pre-coated aluminized zinc steel, that is, aluminized zinc steel plate is used as the substrate, and then the aluminized zinc steel plate is continuously painted in the form of a coil. It is a coated steel that combines the corrosion resistance of galvanized steel with the better durability and heat reflectivity of aluminum-zinc alloy coated steel (Galvalume).

Pattern Coil

Solid Color

To make PPGL steel, a layer of paint or coating needs to be applied to the Galvalume or galvanized steel base. This coating provides additional corrosion protection, improves the appearance of the steel, and extends its life. Due to its excellent heat and corrosion resistance, it has become the material of choice for a wide range of construction applications. Under normal environmental conditions, its service life can reach 15 years or even longer.

PPGL Steel Specifications

| Item | Product Parameter |

| Substrate | GL |

| Thickness | 0.12-1.2 mm |

| Width | 600 ~ 1250 mm |

| Coil Weight | 3-8 tons, can be customized |

| Coatings | PE , SMP , HDP , PVDF |

| Paint Thickness | Top side:11 ~ 35μm |

| Back side: 5 ~ 14μm | |

| Paint Surface | matt / wrinkled / glossy |

| Colors | As per RAL Color, can be customized |

| Monthly Production | 5000 ~ 10000 tons |

| Package | Standard Export Package |

PPGL Steel Processing

The production process of PPGL steel is the same as that of PPGI steel. It uses aluminized zinc plate as the substrate. After surface pretreatment (chemical degreasing and chemical conversion treatment), one or more layers of organic coating are applied on the surface, and then baked and cured.

PPGL Steel Price – Influencing Factor

The pricing of PPGL (pre-coated aluminized zinc steel) coils is affected by a variety of factors, with different degrees of influence for each factor.

Raw Materials

The cost of raw materials has important factors. The price of aluminum-zinc steel plates as substrate will change according to raw material supply, global steel market conditions and trade barriers. Similarly, the cost of pre-applied coatings (including paints, primers and other additives) will vary based on raw material pricing, quality standards, and the complexity of the coating composition.

Paint Coating

Coating parameters can also affect PPGL pricing. High-quality coatings with higher properties, such as higher corrosion resistance or color retention, are often more expensive. Coatings with special characteristics, such as heat reflective or textured surfaces, may also be more costly due to the need for additional production processes.

Specifications

PPGL coil specifications (such as width, thickness and length) can also affect product pricing. Custom size or non-standard specifications may require additional production steps and lead to higher material waste, leading to higher prices. In addition, quantity and order size will also affect prices. Larger orders often benefit from economies of scale, allowing for volume discounts or better pricing arrangements.

If you have any needs, please leave a message and we will provide you with a quote and answer.

How To Choose PPGL Steel Suppliers

So, in a large number of quotations, how to buy suitable PPGL steel at a cheap and suitable wholesale price? The first thing is that you need to find a suitable supplier. The same price comparison quality, the same quality comparison service, the same service comparison price, through the comparison of various channels to select the manufacturer you want to cooperate with, of course, very often need to consider the delivery time, logistics convenience and other conditions.

Wanzhi Steel is committed to being the best service provider and providing you with the best and most suitable service.