GalvaNized Steel

What is galvanized steel like?

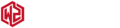

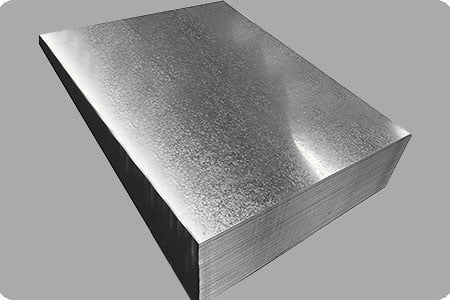

The appearance color of galvanized steel is dark, gray or light gray. After the steel is galvanizing, a pattern will appear on the surface, called glitter. This gives the metal a blotchy appearance, as if spots of different colours were scattered across the metal surface. This crystalline pattern can be seen in dark and light spots throughout the surface. This is in stark contrast to untreated steel, which is usually uniform in color and smoother.

What is galvanzied meaning?

Galvanized refers to the surface treatment technology of plating a layer of zinc on the surface of metal, alloy or other materials to play the role of beauty, rust prevention and so on. The most common method is hot-dip galvanizing, in which the parts are coated by submerging them in a bath of hot , molten zinc .

What is the difference between galvanized steel and ordinary steel?

First of all, corrosion resistance:

galvanizing steel is coated with a layer of zinc, so that it has better corrosion resistance and can resist environmental erosion to a certain extent, while ordinary steel is easy to rust.

The second is the appearance:

the surface of galvanizing steel shows the unique silver luster of galvanizing steel, which is different from that of ordinary steel.

Then there is the price: because the galvanizing process increases the cost, the price of galvanizing steel is usually higher than that of ordinary steel.

What is the process of galvanized steel?

Galvanizing refers to the surface treatment technology of plating a layer of zinc on the surface of metals, alloys or other materials to play a beautiful and anti-rust role. Common methods are hot galvanizing and cold galvanizing.

Hot dip galvanizing is to first pickling the steel parts, remove the iron oxide on the surface of the steel parts, and then clean the steel structure through ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and finally put the steel structure to be derusted into the zinc liquid at about 500℃, so that the zinc layer is attached to the surface of the steel structure.

Cold galvanizing, also known as electric galvanizing, is the process of forming a uniform, dense and well-combined metal or alloy deposition layer on the surface of the workpiece by electrolysis.

Why Use Galvanized Steel?

Galvanized steel has many advantages over other forms of steel, so it is widely used in many industries.

1、First of all, it has strong corrosion resistance, because the surface of galvanizing steel is covered with a layer of zinc, so that galvanizing steel has a strong resistance to corrosion substances such as atmosphere, water and soil.

2、Galvanizing steel can keep its surface smooth for a long time in harsh conditions.

Secondly, the price of galvanizing steel products is relatively low compared with other metal products, and the economy is strong.

3、Therefore, it is widely used in construction, transportation, manufacturing and other fields. And galvanizing steel has good weldability, galvanizing steel can be connected by oxyacetylene welding, arc welding and MIG/MAG welding, and the weld strength is high, air tightness is good, reliability is strong.

4、The high temperature resistance of galvanizing steel is good, the protective zinc layer of galvanizing steel can withstand high temperature and will not cause corrosion due to the change of temperature.

5、Galvanizing steel is a recyclable material, so it can be reused or recycled at the end of its service life.This makes it a more sustainable choice than other materials.

Which industries use galvanized steel?

Galvanizing steel is used in all walks of life, in the field of construction, manufacturing, transportation, home and other fields are very widely used.

For example, in the construction industry, because Galvanizing steel is not easy to rust, corrosion resistance, durable and other characteristics, making the building structure more solid and beautiful. Therefore, it is commonly used in the construction of roofs, exterior walls, floors, balconies and railings, and then it is also widely used in the manufacture of doors and Windows, steel structures, steel frames, supports and other parts.

In short, galvanizing steel has become an indispensable part of modern materials because of its anti-corrosion, durability, beauty and other characteristics. With the continuous progress of science and technology and the improvement of people’s requirements for material quality, the application prospect of galvanizing steel will be broader.

Galvanized steel supply chain —— Wanzhi

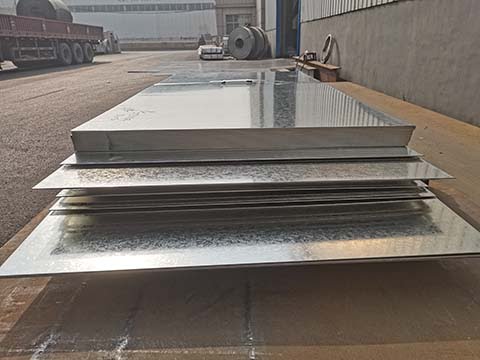

At present, Wanzhi Group provides the production and sales of conventional types of galvanized steel, among which there are different brands of galvanized steel, such as 0.5-2.0mm*1250 mm, Z40, Z60, Z80, Z120, Z180, Z275, big zinc bright, small zinc bright, zero bright and so on. the zinc layer thickness and surface effect of galvanized steel can be customized according to the application scene.

Galvanized steel factory

Wanzhi steel has a production plant in Shandong Province with eight production lines with an annual output of more than 620000 tons. In addition, we have further processing equipment, such as rolling equipment, the production of GI corrugated roof panels. In Wanzhi steel, we also provide cutting, cutting, profile and other services. In addition, we have advanced testing equipment and experimental equipment to ensure that our products meet industry standards. Of course, we can also accept third-party inspection.

Welcome to contact us and plan your visit! Make a free enquiry!