PPGI Roofing Sheet

What is PPGI Roofing Sheet ?

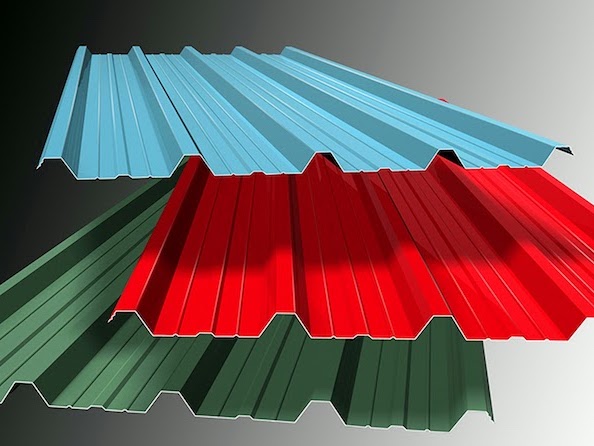

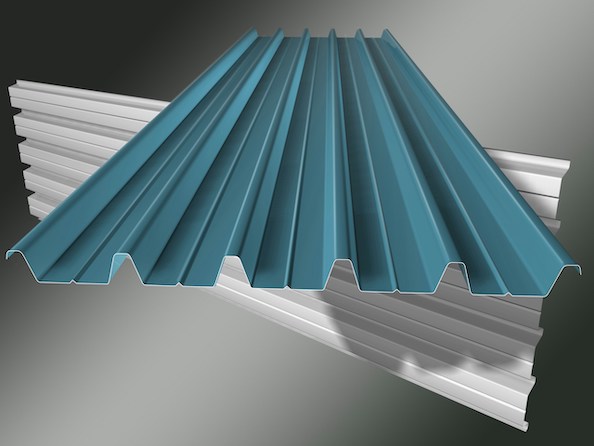

PPGI roofing sheet is the abbreviation of pre-painted galvanized steel roofing sheet. PPGI roofing sheet is a building material consisting of pre-coated hot-dip galvanized mild steel sheet that is cold rolled to create a linear corrugation pattern in it. The corrugation increases the bending strength of the sheet in the direction perpendicular to the corrugation.

PPGI roofing sheet is beautiful, economical and durable, and it is also light, which makes it easy and fast to install, meeting all your commercial, agricultural, residential and factory needs.

PPGI Roofing Sheet Specification

| Item | Product Parameter |

| Name | Color Coated Galvanized Corrugated Sheet Roofing Sheet |

| Substrate | GI (Galvanized) |

| Thickness | 0.12-1.2 mm |

| Width | 600 ~ 1250 mm |

| Surface treatment | Oil, galvanized, color coated |

| Colors | As per RAL Color, can be customized |

| Monthly Production | 5000 ~ 10000 tons |

| Apply | Buildings, roofing, Windows, automotive use, household appliances |

| Delivery Time | 10-35 days after receive payment |

| Package | Standard Export Package |

PPGI Roofing Sheet Production Process

PPGI Roofing Sheet Price : Influencing Factors

The main factors affecting the price of color roof panels are: raw materials (basic steel) and zinc layer thickness, paint thickness, paint material brand, steel plate thickness, packaging mode and so on.

1. Zinc thickness: The price depends on the thickness of zinc. For example, the price difference between 20 grams of zinc and 50 grams of zinc is very large. If the customer does not require zinc, it is recommended to choose zinc steel coils of about 23-25 grams.

2. Paint thickness: Color coated rolls are divided into single coating and double coating. The price of single coating color coated rolls is lower than that of double coating color coated rolls. Customers need to choose color coated rolls according to their use and environment. Regarding the impact of paint materials and brands on the price of color coated rolls, customers also need to choose the paint brand according to the application location and environment of color coated rolls.

PPGI roofing sheet

Color Galvalume

3. Steel plate thickness and basic steel: The thinner the steel plate, the higher the price, because the thinner the color coating roller area is less than 1 ton, more paint will be used and the processing time will be longer.

4. Packaging: Packaging includes simple packaging, standard export packaging, and special packaging. Simple packaging, simple protection performance and cheap price. The outer layer of standard export packaging is waterproof kraft paper and galvanized iron sheet packaging. The sides of the coil are also protected with galvanized iron sheet. It can better protect the surface of the color coated roll from damage and has a good waterproof effect. This packaging method is the most widely used.

Application Of PPGI Roofing Sheet

PPGI roofing sheet & the application

Infrastructure, greenhouse construction, high-speed guardrail, photovoltaic bracket, sports equipment, electrical appliances, etc

PPGI Roofing Sheet Manufacturers

As a wholesale supplier and manufacturer operating in China for many years, we have been engaged in the iron and steel industry for more than a decade and developed many loyal customers in Europe, South America, the Middle East, Africa and other places. Wanzhi Steel has a production plant and a foreign trade company, we provide a variety of different shapes and sizes of PPGI roof panels. Here, we have a choice of products ranging from 0.2 to 0.8 mm in thickness and 600 to 1250 mm in width.

roof works

In addition, the color and pattern of the roof panel can also be customized. If customers need, we can also supply other metal products. More importantly, we will provide competitive prices for customers with large orders. If you have a demand for steel, welcome to negotiate with us!

How To Choose PPGI Roofing Sheet ?

First, when selecting PPGI roofing Sheet, thickness and color are usually considered.

Secondly, you also need to pay attention to the mechanical properties of the substrate, such as yield strength.

And the zinc layer weight and coating type of galvanized steel plate.

At Wanzhi, you can get exactly everything you want and look forward to your inquiry.