Tin plate

What is Tinplate ?

Tinplate is also called tin-plated iron. Tinplate is the common name for tin-plated steel sheet. Its English abbreviation is SPTE, which refers to cold-rolled low-carbon steel sheet or strip with a thin layer of pure tin on the surface. The tin layer is non-toxic and tasteless, and the surface is bright. It mainly prevents corrosion and rust. It combines the strength and formability of steel with the corrosion resistance, solderability and beautiful appearance of tin in one material. It has the characteristics of corrosion resistance, non-toxicity, high strength and good ductility.

Tinplate Can

Production process of Tinplate

Tinplate Composition

According to the production process, it is divided into hot-dip tin steel sheet and electroplated tin steel sheet. Commonly used cans or beverage cans are made of tinplate.

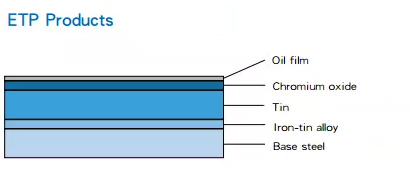

Tinplate consists of five parts, from the inside to the outside, steel substrate, tin-iron alloy layer, tin layer, oxide film and oil film.

The tin coating thickness of the hot-dip method is thick and uneven, the coating thickness is difficult to control, the tin consumption is large, the cost is high, and the efficiency is low. Its application is limited, so it is gradually eliminated by the electroplating method.

The electroplating method is to use the electroplating process to uniformly plate a tin film on the steel plate substrate. It has high productivity, low cost, thin and uniform coating, can produce different coating thicknesses, and can also be tinned on one side or two sides. The electroplating methods mainly include alkaline electroplating, sulfate electroplating, halogen electroplating and borofluoric acid electroplating.

The overall process of tinplate electroplating is to roll low-carbon steel into thin steel plates, pickling, cold rolling, electrolytic cleaning annealing, flattening, trimming, and then cleaning, electroplating, soft melting, passivation treatment, oiling and shearing into tinplate plate products. The tin used for tinplate is high-purity tin (Sn>99.8%).

Main Features of Tinplate

The biggest feature of tinplate is corrosion resistance, easy processing, can be punched and formed, can be welded, easy to install and print, and non-toxic and harmless, so it is suitable for the packaging of various foods, beverages, and medicines. At present, it is mainly used as a packaging material for canned food.

The tin-plated layer has the dual properties of electrochemical cathode and anode protection. On the inner wall of a food can filled with a complex mixture (or in a weak acid solution) and with a certain vacuum, the potential of the tin-plated layer is lower than that of the base material iron. Tin is the anode, and its dissolution protects the iron. During the shelf life of the food can, the amount of tin dissolved is basically harmless to the human body. While the outer wall is in the atmospheric solution, the tin-plated layer is in a cathodic protection state, with sufficient chemical stability, which is unmatched by other canning materials.

Tinplate types and uses

Electroplated tinplate can be classified according to the degree of tempering, amount of electroplating, steel type, annealing method, surface treatment, etc. Our company’s tinplate products have excellent solderability, weldability, formability and surface appearance, and are widely used in food cans, beverage cans, 18-liter cans, art cans, spray cans, various bottle and can covers, household electrical appliances, electrical material parts, oil filters, wire sheath materials, etc.

Tinplate Canning Jars

Tinplate Can lid

Classification representation

| Classification method | Category | Symbol or description |

| By annealing method | Continuous annealing | CA |

| Box annealing | BA | |

| By material grade | Food grade | MR |

| Chemical grade | SPCC | |

| By surface condition | Bright surface | B(Bright finish) |

| Stone surface | St(Stone finish) | |

| Silver surface | S(Silver finish) | |

| Matte surface | M(Matt finish) | |

| By tin plating amount | Equal thickness tin plating amount | 2.8/2.8, 5.6/5.6, 8.4/8.4, 11.2/11.2 |

| Differential thickness tin plating amount | 5.6/2.8, 8.4/2.8, 8.4/5.6, 11.2/2.8, 11.2/5.6, 11.2/8.4, 15.1/5.6 | |

| By surface quality | First-level tin plating plate | I |

| Second-level tin plating plate | II | |

| Chemical resistance (good corrosion resistance) | K-plate | Meet the four tests Acid hysteresis value (PL), Iron solubility value (ISV), Tin crystallinity (TCS), Alloy-tin couple current value (ATC) |

| J-plate | Meet the three tests Acid hysteresis value (PL), Iron solubility value (ISV), Tin crystallinity (TCS) |

Application Scenario

Tin-plated steel sheet has demonstrated its wide applicability in many fields. It is not only the preferred material for food and beverage packaging, but also widely used in oil containers, chemical tanks and many other storage purposes. With its unique properties, it provides comprehensive physical and chemical protection for the contents.

Food preservation cans: Tin-plated steel ensures the cleanliness and safety of food, greatly reduces the risk of corruption, and effectively avoids health hazards. At the same time, it conforms to the trend of modern people pursuing convenient and efficient diets.

Beverage containers: Whether it is juice, coffee, tea, sports drinks, or even carbonated drinks, beer, etc., they can all be packaged in tin-plated steel cans. Its strong plasticity makes the can shape changeable. Regardless of height, weight, and size, it can meet the diversified needs of beverage packaging in the current market and the personalized preferences of consumers.

Grease storage cans: Light can stimulate and accelerate the oxidation of fats, leading to nutrient loss and even the production of substances that are unhealthy, especially destroying fat-soluble vitamins such as vitamin D and vitamin A. The oxygen in the air is also the culprit for the oxidation of food fats, which will reduce the effective components of protein and destroy the vitamin structure. The opacity and excellent sealing of tin-plated steel make it an ideal solution for preserving oily foods.

Chemical containers: Tin-plated steel is recognized as the best material for chemical packaging because of its high strength, excellent protection, and resistance to deformation, shock and fire.

Spray cans and other special cans: Tin-plated steel cans that withstand high temperature and pressure are very suitable for manufacturing spray cans that need to withstand high-pressure filling.

Tin Plate Copper

Tinplate coil

Tinplate Suppliers – Wanzhi

There are many suppliers to choose from in the market. When choosing a supplier, you need to pay attention to many things, such as whether they are experienced, whether they can deliver goods quickly, etc. Wanzhi Company is a good choice. We not only have an elite sales team, but also have our own factory in Shandong, China, which can produce all kinds of products you want. We welcome your inquiries and consultations, and you can also come to visit us on site. We are your trusted supplier partner.