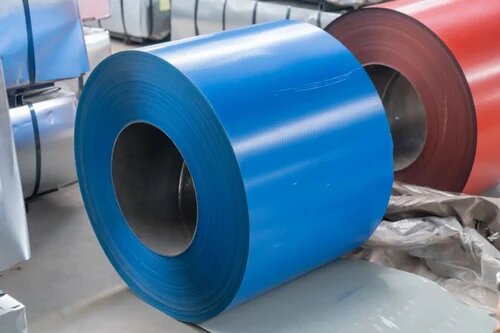

Color Coated Aluminum Coil

Definition of color coated aluminum coil

Color coated aluminum coil is a surface-treated aluminum alloy material. Its main process includes painting the aluminum substrate. Common coating types include fluorocarbon (PVDF) color coating and polyester (PE) color coating. The warranty period of polyester paint is 10 years, and the warranty period of fluorocarbon paint is more than 20 years. Color-coated aluminum coil is widely used in construction, industry, electronic products and other fields. It has the characteristics of light weight, beautiful appearance and corrosion resistance.

Aluminum coil

Production process of color coated aluminum coil

The production process of color-coated aluminum coil mainly includes the following steps:

Surface pretreatment: including degreasing, cleaning and chemical conversion treatment.

Painting: The paint is continuously applied to the surface of the aluminum coil by roller coating.

Baking and cooling: Baking and cooling are carried out after painting to form the final color-coated aluminum coil product.

Material of color coated aluminum coil

At present, the two most common materials on the market are pure aluminum alloy and alloyed aluminum alloy:

(1) Pure aluminum alloy is divided into ordinary type and high hard type:

Ordinary type generally uses cold-rolled steel plate as raw material to make a thin plate with a thickness of 0.5-1.0mm as the base material, and is rolled by a cold rolling mill. This type of product is gradually eliminated from the market due to its low strength, easy deformation, easy oxidation and discoloration, and poor appearance quality. The main products sold on the market are high hardness and patterned products

RAL6015 Aluminum Coil

Color coated Aluminum Coil

(2) Alloyed aluminum alloy:

Alloying is to add some special elements such as silicon, calcium, titanium, phosphorus, copper, chromium, nickel, manganese, vanadium, cobalt, tin, zinc, boron, and lead to ordinary low-carbon steel or low-alloy steel to form a special composite metal to obtain a high-strength material. The advantages of alloying are higher strength, less prone to deformation and cracking, more beautiful appearance, smooth and flat, better wear resistance, and longer service life, and are widely used in the production and manufacturing of various mechanical parts.

Advantages of color coated aluminum coil

Lightweight: easy to transport and install.

Beautiful: diverse surface coatings and rich colors.

Corrosion-resistant: resistant to salt, alkali, acid rain corrosion, extending service life.

Environmental protection: no toxic gas release, environmentally friendly and safe.

Processability: can be directly processed to meet various processing needs.

Aluminum-Coil in various colors

Factory direct aluminum coil

Because the performance of aluminum alloy is very stable and not easy to corrode, the surface can be guaranteed to be non-fading for at least 30 years after special treatment. Moreover, due to its low density and high hardness, the weight per unit volume is the lightest among metal materials. Color-coated aluminum coils are treated with surface coating to extend the service life of aluminum.

Color-coated aluminum coils are resistant to salt, alkali, acid and rain corrosion. After self-corrosion, they will not produce toxic bacteria, release any toxic gases, cause rust on the keel and fixings, and are flame retardant.

Application of Color-coated Aluminum Coil

Color-coated aluminum coils are widely used in the following fields due to their excellent performance:

Architecture: used for aluminum-plastic panels, industrial plant roofs and walls, aluminum blinds, aluminum ceilings, etc.

Industry: used for industrial plant roofs and walls.

Electronic products: used for the shell and internal structure of electronic products.

Furniture industry: used for the decoration and structural parts of furniture.

Electrical industry: used for the shell and internal structure of electrical equipment.

ral 4006 Purple aluminum coil

Red aluminum alloy coil

Color-coated aluminum coils have become one of the most popular top-level decorative materials. Colored aluminum is widely used in doors and windows, sun rooms, balcony encapsulation and other fields of high-end real estate.

Color coated aluminum coil supplier

Wanzhi Steel was founded in 2011 and has experienced more than ten years of development. With a complete production and sales team and strict production specifications, choosing us is a very wise decision. We have served thousands of customers, some of whom are already our partners and will purchase goods from us for a fixed period of time. We support customized production and can produce corresponding products according to the specific requirements of customers. Free consultation is welcome.