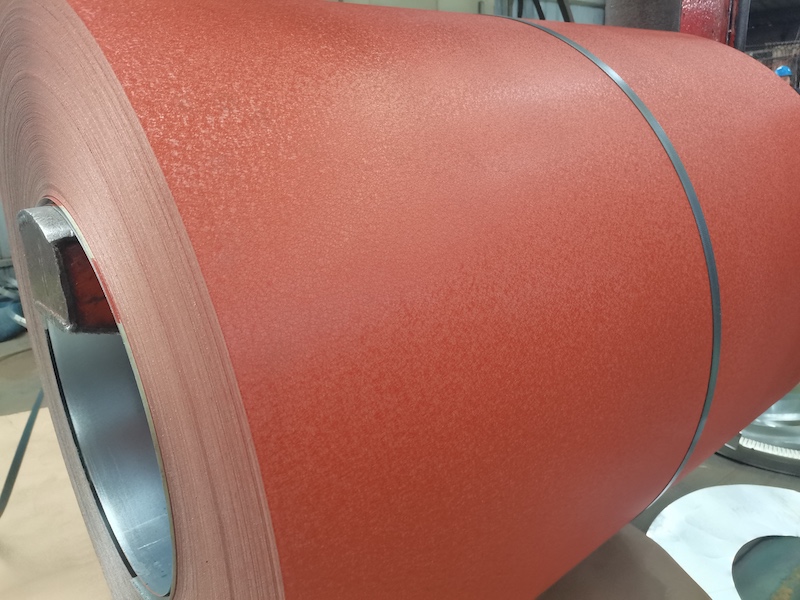

Reticulated Color Coated steel

What is Reticulated Color Coated ?

Reticulated color coated steel boards are also called mesh color-coated boards, sometimes called suede color-coated boards and wrinkle-coated boards. It is a coating with special performance paint on the surface of steel plate. In the early stage of paint curing, the surface paint first solidifies and shrinks; in the later stage of curing, the surface absorbs the shrinkage of the lower layer; finally, the suede color coated plate is a kind of wrinkled (fluffy, reticulated) coating surface with suede effect after drying, showing a three-dimensional effect.

After the finished product is painted, the panel surface will have a wrinkle-like (velvet-like, mesh-like) appearance, a smooth hand feel, and significant advantages such as beauty, wear resistance, and scratch resistance, bringing a high-quality appearance to buildings or home appliances. .

The main features of reticulated color coated

(1) It can be painted in various colors, and the appearance is bright and gorgeous. It can enhance the contrast with the surrounding environment, thereby reducing the sense of distance of the building and having a good reticulated visual effect;

(2) It feels smooth and has a three-dimensional feel. Most of them are produced using warm or dark paint, which has a heat absorption effect and a psychological warming effect;

(3) The coating has a “diffuse reflection feature” for sunlight. When used in industrial plants, the diffuse reflection feature of the coating surface makes the building color soft and avoids light pollution

(4) It is durable, wear-resistant, and scratch-resistant.

Coated coils have the advantages of both organic polymers and steel sheets. They have the good coloring, formability, corrosion resistance and decorative properties of organic polymers, and the high strength and easy processing of steel sheets. They can be easily processed by punching, bending, deep drawing, welding, etc. This makes the products made of organic coated steel sheets have excellent practicality, decorativeness, processing and durability.

Reticulated Color Coated Classification

There are many varieties of coated boards, about more than 600 types, but there is no unified classification method. Because it is difficult to find a standard to distinguish among the many varieties. At the same time, each manufacturer has its own unique equipment and processes, and there are many types of products. Now it is only classified according to general habits

1.Classification by substrate used

Substrates commonly used for organically coated steel sheets include: cold-rolled sheets, hot-dip galvanized sheets, electro-galvanized sheets, alloy sheets, galvanized aluminum sheets, electro-galvanized zinc alloy sheets, tin-plated sheets, chromium-plated sheets, aluminum sheets, etc.

2.Classification by processing technology

According to different coating methods, there are organic coated steel plates made by roller coating, spray coating, powder coating, lamination, printing, etc. Depending on the number of coatings, there are organic coated steel plates made by different processes such as one coating and one drying, two coatings and two dryings, three coatings and three dryings, four coatings and four dryings. According to embossing or printing processing, it can be subdivided into wood grain plate, marble grain, leather grain, cement mortar grain and other coated steel plates.

3.Classification by coating type

Usually classified according to the coating used to make organic coatings, there are polyethylene-coated steel plates, polycool-coated steel plates, acrylic-coated steel plates, fluorocarbon-coated steel plates, silicon-polycool-coated steel plates, etc.

4.Classification by coating performance

According to the performance characteristics of organic coatings, there are high weather-resistant coating boards, high-temperature resistant coating boards, self-extinguishing coating boards, sterilization coating boards, non-stick snow coating boards, fingerprint-resistant coating boards and self-lubricating coatings. Board etc.

5.Classified by special coatings and uses

For example, there are epoxy zinc-rich coatings, organically coated steel plates with cold-rolled steel plates as the substrate, surface flocked steel plates. And some special machine-coated laminated boards, such as wood-tied membrane boards, sandwich panels, anti-vibration boards, etc.

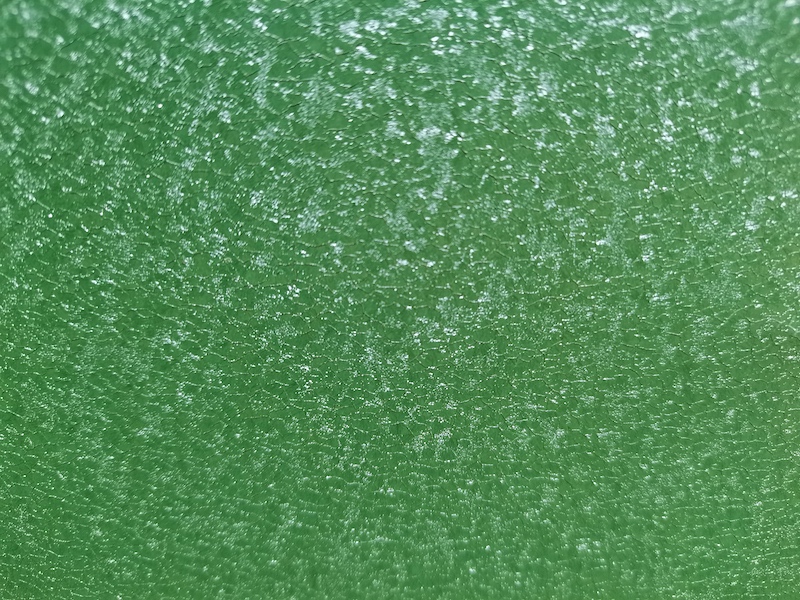

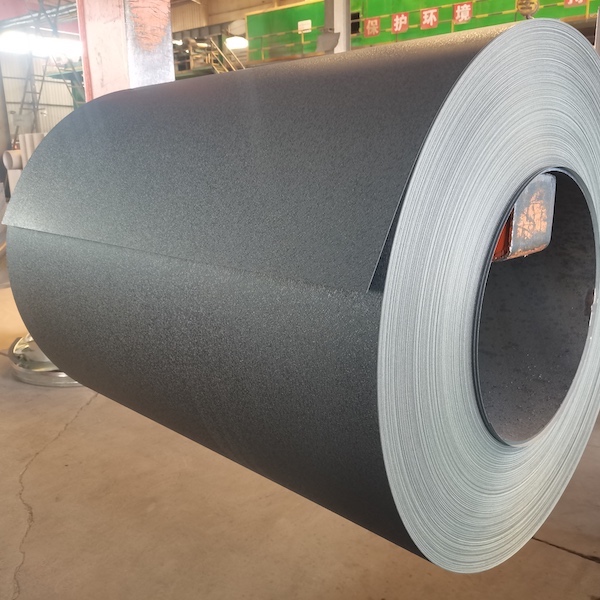

RAL 9005 color coated

reticulated color coated

Application of reticulated color coated

The coating of the reticulated color-coated steel presents a “diffuse reflection feature” to sunlight. It is applied to industrial plants. Due to the “diffuse reflection feature” of the coating surface, the overall building color is soft and light pollution is avoided. It is applied to villas, high-end integrated house roofs, and high-rise buildings to enhance the contrast with the surrounding environment and reduce the visual deviation of pilots flying over the building.

The surface has a good “reticulated” visual effect. Because it is mostly produced with warm or dark paint, it has a certain heat absorption effect and psychological setting effect when used in cold northern regions.

Due to its low light effect and close to nature. The reticulated color-coated plate is widely used in indoor and outdoor decoration of high-rise buildings, villas, high-end integrated houses, industrial buildings, etc., and is also used in home appliance panels, purification clean workshops, metal carved panels, exterior wall insulation panels and other fields. It is especially widely used in the production of color steel antique tiles on the roofs of civil buildings, villas, etc.

Reticulated PPGI Coil

Green Reticulated

Common specifications range from 0.2 mm to 1.0 mm. Commonly used widths in China are 1000 and 1200. Customers from various countries mainly purchase 940 mm, 1200 mm, 1219 mm, 1250 mm, etc.

Reticulated Color Coated for sales

Good companies sell good products. If you want to purchase products with good quality and good prices, you need to look carefully. As a steel foreign trade company with more than ten years of operation, Wanzhi Company has successfully served thousands of customers. Whether you are a dealer, a processing factory, or a corporate project construction, or personal construction needs, we have successful cases. Looking forward to your inquiries, we welcome you to visit our company and factory.