Chapa laminada en frío

¿Qué es el acero laminado en frío?

El acero laminado en frío es un tipo de acero laminado en caliente que ha sido sometido a un procesamiento adicional para mejorar sus dimensiones y propiedades mecánicas.

Durante el laminado en frío, el acero laminado en caliente enfriado pasa a través de otra serie de rodillos a temperatura ambiente.

Como el material ya no está caliente ni es maleable, se necesita más presión para comprimirlo en la forma deseada.

Aunque este proceso requiere más mano de obra y es más costoso que el proceso de laminación en caliente, puede lograr dimensiones más precisas y una mejor calidad de superficie.

Lista de parámetros de chapa de acero laminada en frío

| Artículo | Parámetros del producto |

| Nombre del producto | Chapa de acero laminada en frío |

| Espesor del producto | 0.2-4.0 mm |

| Ancho | 600-1500 mm |

| Longitud | 2000-6000 mm |

| Contenido del elemento | C (0.02%~0.1%) Si (0.03%~0.8%) Mn (0.25%~1.5%) P (0.03%~0.06%) S (0.02%~0.05%) |

| Marcas comunes | Q195/ SPCC/ SPCD/ SPCE/ ST12~15/ DC01/ DX51D |

| Capacidad de producción | 10000 toneladas por mes |

| Cantidad mínima de pedido | 10 toneladas |

| Paquete | Paquete de exportación estándar |

Parámetros comunes de la chapa laminada en frío

| Marca | Espesor (mm) | Tratamiento de superficies | Solicitud |

| SPCC | 0.3-3.0 | Superficie sin tratar | Placa de uso general |

| SPCE | 0.3-3.0 | Superficie sin tratar | Piezas de embutición profunda, piezas de punzonado |

| SPCD | 0.3-3.0 | Superficie sin tratar | Chapa común laminada en frío |

| DC01 | 0.3-3.0 | Aceite lubricante para tratamiento de superficies | Electrodomésticos, autopartes |

| DC03 | 0.3-3.0 | Aceite lubricante para tratamiento de superficies | Electrodomésticos, autopartes |

| ST12 | 0.3-3.0 | Tratamiento de superficies fosfatado | Chapa laminada en frío de uso general |

| ST13 | 0.3-3.0 | Tratamiento de superficies fosfatado | Automóviles y electrodomésticos |

La tabla anterior muestra los modelos y especificaciones de laminado en frío más comunes, cada uno de los cuales corresponde a diferentes tamaños y parámetros. Estas especificaciones y modelos se utilizan ampliamente en la metalurgia, la fabricación mecánica, la construcción, la fabricación de automóviles y otros campos.

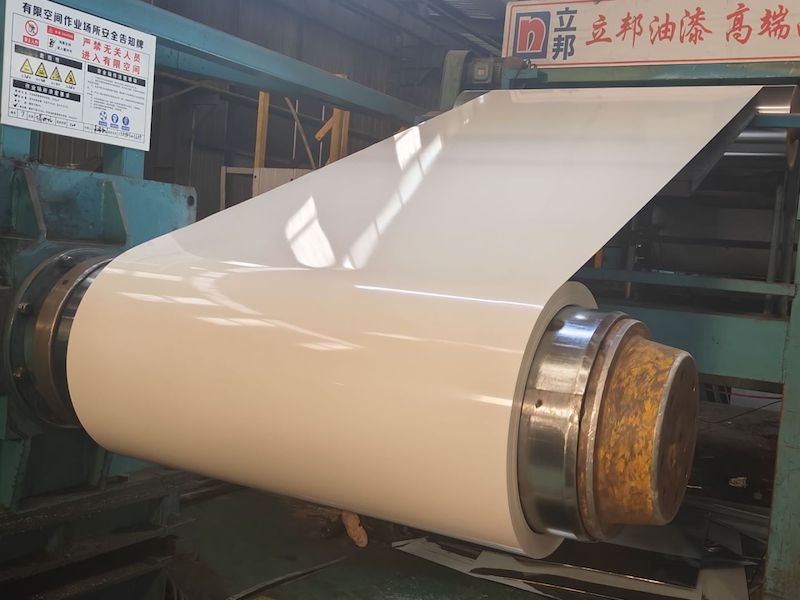

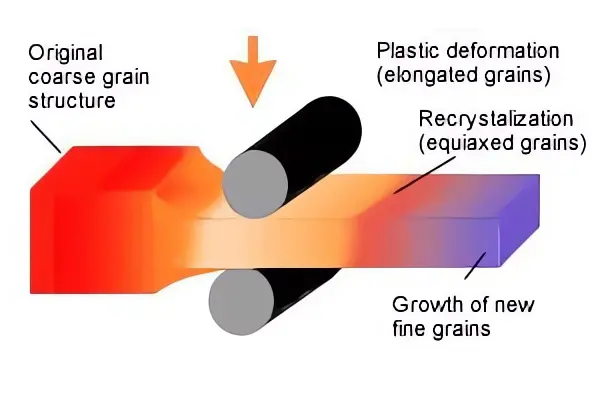

¿Qué es rolling?

El laminado es un tipo de proceso de conformado de metales que utiliza una serie de rodillos para cambiar de forma, mejorar la uniformidad y mejorar las propiedades mecánicas de los materiales. El acero laminado se puede dividir en dos tipos: acero laminado en caliente y acero laminado en frío, que tienen características diferentes y son adecuados para diferentes aplicaciones. Al seleccionar materiales de acero laminado para un proyecto, es importante comprender las diferencias entre los dos tipos y cómo afectan su rendimiento.

Línea de producción de chapas y bobinas de acero laminado en frío

Diferencias entre acero laminado en frío y acero laminado en caliente

La principal diferencia entre el acero laminado en caliente y el acero laminado en frío radica en sus métodos de procesamiento.

El acero laminado en caliente se lamina por encima de la temperatura de recristalización del material, mientras que el acero laminado en frío se lamina por debajo de la temperatura de recristalización del material. El acero laminado en frío es esencialmente acero laminado en caliente y se procesa posteriormente en materiales laminados en frío. Diferentes grados y especificaciones de acero pueden ser laminados en caliente o laminados en frío. La diferencia entre el acero laminado en frío y el acero laminado en caliente radica principalmente en los siguientes aspectos:

Calidad de la superficie:Los bordes y superficies del acero laminado en caliente suelen ser rugosos y necesitan descarburación u otro tratamiento antes de poder utilizarse en operaciones de producción posteriores. Por el contrario, la superficie del acero laminado en frío suele ser brillante y lisa y puede utilizarse directamente en operaciones de producción.

Dureza del material:El acero producido mediante el proceso de laminación en frío tiene mayor resistencia y dureza que el producido mediante el proceso de laminación en caliente.

Estrés interno:Cuanto mayor sea la resistencia y dureza del material obtenido mediante el proceso de laminado en frío, mayor será la tensión interna. Estas tensiones deben eliminarse antes de procesar el material; de lo contrario, la pieza o producto final puede deformarse.

En conclusión, al evaluar la selección del acero de un proyecto, es importante tener en cuenta que algunos materiales son más efectivos que otros en algunos usos.

Saber qué acero proporciona el rendimiento adecuado para una aplicación particular puede evitar gastos excesivos en materias primas y ahorrar tiempo a largo plazo.

Campo de aplicación de la chapa de acero laminada en frío

La chapa de acero laminada en frío se utiliza ampliamente en la fabricación de varios tipos de productos metálicos en el campo industrial, como automóviles, electrodomésticos, fabricación de maquinaria, materiales de construcción, muebles y otros campos, y ha sido ampliamente utilizada y reconocida en la apariencia del producto, el rendimiento, la durabilidad del material y el respeto al medio ambiente.

Proveedor de chapa de acero laminada en frío

Hay empresas proveedoras de acero laminado en frío en todo el mundo. Al elegir proveedores, asegúrese de elegir empresas con buena reputación, como Acero WanzhiComo empresa líder en la fabricación y venta de productos de hierro y acero en China, contamos con nuestra propia fábrica en la provincia de Shandong y un equipo de servicio profesional en Zhengzhou, provincia de Henan. Hemos desarrollado un equipo de producción profesional para producir acero CR con un tamaño preciso, una superficie hermosa y buenas propiedades mecánicas. Además, contamos con un estricto sistema de control de calidad. Puede venir al lugar para verificar su placa de acero. Además, también estamos sujetos a inspección por parte de terceros. No solo eso, también contamos con un sistema de servicio completo.

Si tiene alguna pregunta al recibir la mercancía, no dude en ponerse en contacto con nosotros. Le devolveremos la llamada en 12 horas. Wanzhi Steel también ofrece un gran descuento para pedidos grandes. Le invitamos a llamar para preguntar por el precio más reciente.