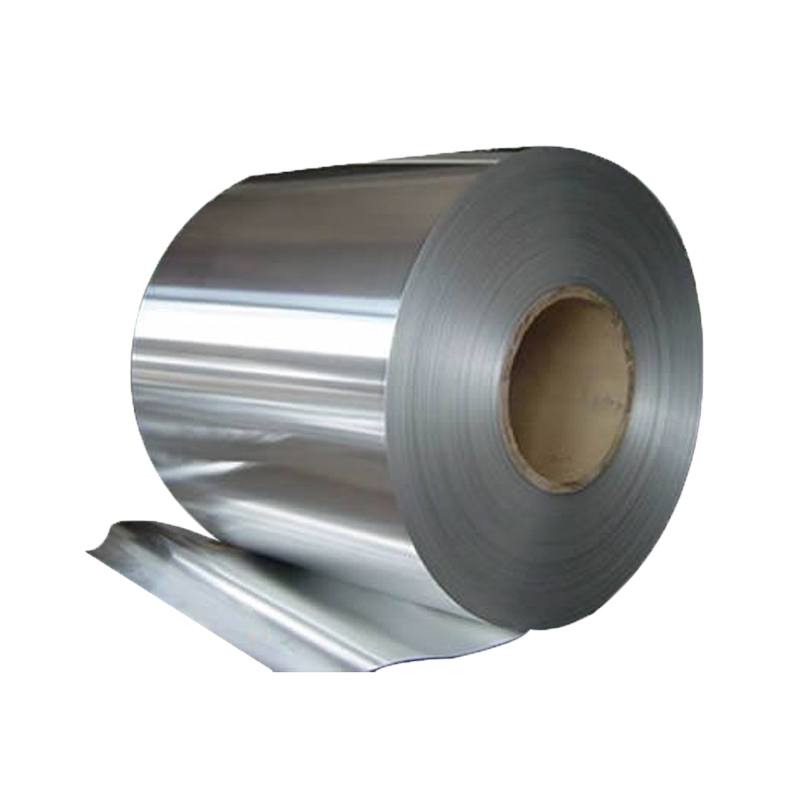

Cold Rolled Coil

What Is Cold Rolled Steel Coil?

Cold rolled steel can be abbreviated to CRS, which is a very malleable material and an ideal choice for applications requiring precision.

It is used in many application scenarios, such as household appliances, furniture, lockers and filing cabinets.In building applications, CRS is usually used to build garages, steel sheds and other industrial buildings.

In short, cold rolling is a process of strengthening steel by changing its shape without using heat.

Unlike hot rolling (such as hot rolled steel), cold rolling can only be carried out when the metal is below its recrystallization temperature. Hot rolling is carried out at high temperature while cold rolling is carried out at room temperature.

Mechanical stress is used to change the structure of the metal. Strain hardening can increase the strength of the metal by up to 20% and improve the surface finish of the metal.

In the process of cold rolling, the metal is subjected to mechanical stress, which will lead to permanent changes in the crystal structure of the metal. This leads to increased strength and usually improves corrosion resistance. In addition to improving its surface finish, another advantage of cold rolling is that the dimensional accuracy will be higher.

Cold Rolled Steel Coil Specification

| Item | Product parameter |

| Product Name | Cold Rolled Steel Coil |

| Product Thickness | 0.12-6.0 mm |

| Width | 600-1600 mm |

| Hardness | Softy,Halfhard,Hardquality |

| Coil Weight | 2.5 – 3 tons, can be customized |

| Surface | Plain |

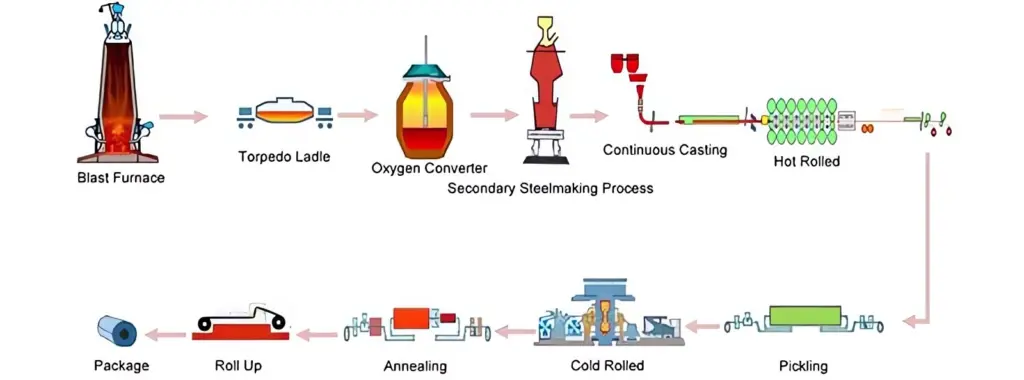

| Workflow | Hot rolling—pickling–phosphating–saponification–cold rolling |

| Brand and use | Cold rolled carbon steel : SPCC(General use) SPCD(For stamping) SPCE(Deep stamping) |

| Cold rolled mild steel : DC01(General use) DC03(For stamping) DC04(Deep stamping) | |

| Application | Automobilemaking,Electricalappliance, Locomotiveandcar,Airlines. |

| Production Capacity | 10000 Tons per Month |

| Package | Standard Export Package |

Properties of Various Grades of Cold Rolled Steel

| Brand | Yield strength (MPa) | Tensile strength (MPa) | Elongation (%) | Plastic strain ratio (r90) | Strain hardening index (n90) |

| DC01 | 140~280 | 270~370 | ≥ 28 | ||

| DC02 | 140~240 | 270~370 | ≥ 34 | ≥ 1.4 | |

| DC03 | 120~210 | 270~350 | ≥ 38 | ≥ 1.8 | ≥ 0.18 |

| DC04 | 120~180 | 270~330 | ≥ 40 | ≥ 2.0 | ≥ 0.20 |

| SPCC | 130~300 | 270~410 | |||

| SPCD | 120~240 | 270~370 | ≥ 1.3 | ||

| SPCE | 120~210 | 270~350 | ≥ 1.8 | ≥ 0.18 |

Cold Rolled Steel Coil Manufacturing Process

Advantages of cold-rolled steel

High strength: After processing, the molecular structure of cold-rolled steel is more compact, so its strength is higher than that of hot-rolled steel and can meet higher strength requirements.

Good toughness: Cold-rolled steel undergoes multiple pressing and stretching during processing, making its molecular structure more uniform and having better toughness performance. In contrast, hot-rolled steel has larger grains and is not as tough as cold-rolled steel.

Good surface finish: The surface of cold-rolled steel is better protected during processing, making its surface finish higher. Therefore, cold-rolled steel is more suitable for applications that require high finish than hot-rolled steel.

High dimensional accuracy: Due to the processing method of cold-rolled steel, its dimensional accuracy can reach ± 0.05mm, which is higher than hot-rolled steel. Therefore, cold-rolled steel has more advantages in situations where higher dimensional accuracy is required.

Cold Rolled Steel Coil Uses

Cold rolled steel is widely used in industry, construction, transportation and other fields of manufacturing and processing. The following are some of the main uses of cold-rolled steel.

Construction:

cold-rolled steel is often used in the manufacture of components in the construction field, such as roofing, wallboards, beams and columns, etc. Cold-rolled steel has good strength, toughness and stability, which is suitable for the manufacture and construction of heavy-duty structures such as high-rise buildings and bridges.

Automobile manufacturing:

cold-rolled steel has good mechanical properties and corrosion resistance, so it is widely used in the production of car body, door, roof and other structural parts.

Transportation:

cold rolled steel is one of the important materials in the field of transportation.

It is used to manufacture components and parts of aircraft, trains, cars and other means of transportation. Such as engines, frames, tires and so on.

Home appliance manufacturing:

cold-rolled steel is also widely used in home appliance manufacturing industry, such as refrigerators, washing machines and so on. It has high strength and hardness, which can ensure the stability and durability of the product.

Military manufacturing:

Because of its high strength and hardness, cold-rolled steel can be used to make tanks, aircraft, missiles and other equipment.

In addition to the above fields, cold-rolled steel are also widely used in manufacturing, energy industry, railway industry, shipbuilding and many other fields.

Cold Rolled Steel Supplier – Wanzhi

With the progress of science and technology and the development of technology, the application of cold-rolled steel in more fields is also expanding. Generally speaking, cold-rolled steel has become one of the indispensable important materials in many fields because of its excellent performance and various application characteristics.

If you exactly want to purchase cold rolled steel, you can consider Wanzhi Steel, we are a production and sales company with more than 10 years, here you are sure to find the right products. Look forward to your consultation.