PPGI STEEl

What Is PPGI Steel?

PPGI is pre-painted galvanized iron, also known as pre-coated steel, coil-coated steel, color-coated steel, etc., typically with a hot dip zinc-coated steel substrate.

The term is an extension of GI, a traditional abbreviation for Galvanized Iron. Today the term GI typically refers to essentially pure zinc (>99%) continuously hot-dip coated steel, as opposed to batch dip processes. PPGI refers to factory pre-painted zinc-coated steel, where the steel is painted before forming, as opposed to post-painting which occurs after starting.

PPGI Steel Specifications

Wanzhi Steel offers pre-painted galvanized coils and plates in different colors and sizes. Here is a parameter table for your reference. Please contact us for a free quote on the item you need.

| Item | PPGI Steel (pre-painted galvanized steel) |

| Substrate | Galvanized steel |

| Grades | DX51D+Z, DX52/53/54D+Z, S280GD+Z, S350GD+Z, S550GD+Z, SECC, etc. |

| Thickness | 0.13 mm-1.5 mm (stock thickness: 0.35/0.4/0.45/0.5/0.6/0.8mm) |

| Width | 600 mm-1,250 mm (stock width: 1000/12oomm) |

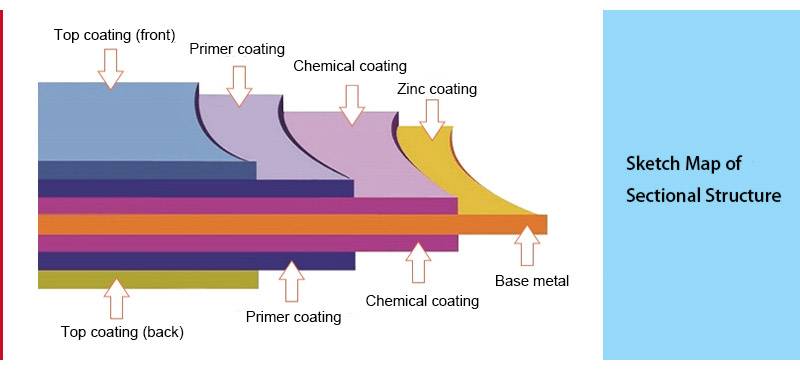

| Paint Types | PE, SMP, HDP, PVDF |

| Paint Thickness | Top: 10-35 μm Back: 5-14 μm |

| Colors | As per RAL Color (custom patterns are available) |

| Annually Production | 320,000 tons |

| Value-added Services | Custom sample, slitting, cutting, stamping, bending, profiling, and other |

| Package | Standard export package or as per your requirements |

What are the features of PPGI

The surface of the ppgi has a unique smooth, flat, and gorgeous star flower, and the base color is silver-white. The special coating structure gives it excellent corrosion resistance. The normal service life of galvanized sheet can reach 25 years. It has good heat resistance and can be used in high temperature environments of 315°C. The coating has good adhesion to the paint film and has good processing performance, and can be stamped, sheared, welded, etc.; Surface conductivity is very good.

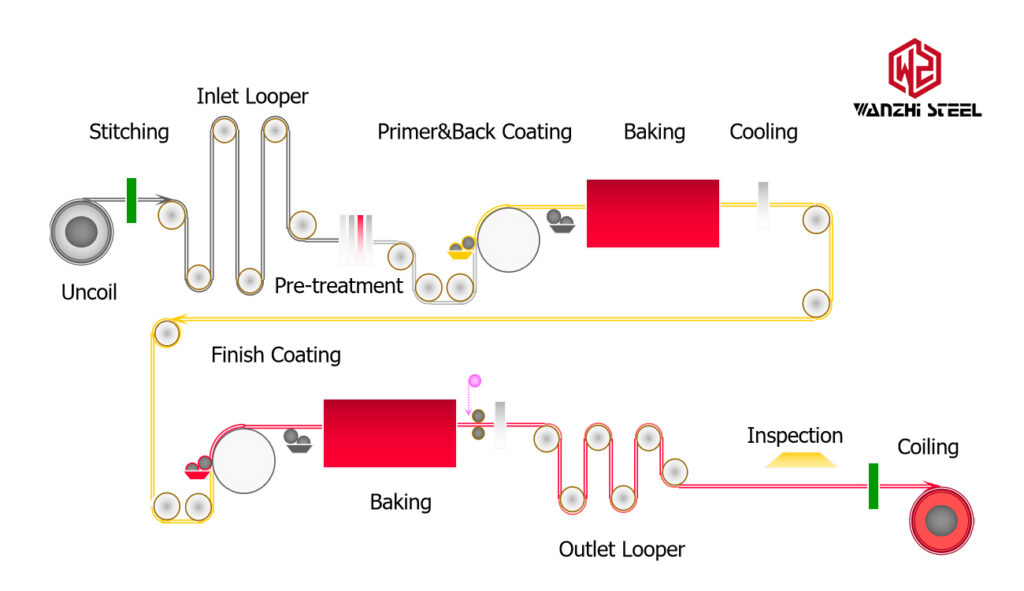

The production process of PPGI steel

What are the use scenarios of PPGI ?

PPGI is widely used in the construction industry, such as the manufacture of corrugated roof panels.

It is also widely used in household appliances industry, automobile industry and engineering industry.

Common application Such as corrugated roof panels, ceiling passageways, industrial cold storage, cold storage, door panels, sandwich panels, etc.

Pre-coated Galvanized Coil Packing

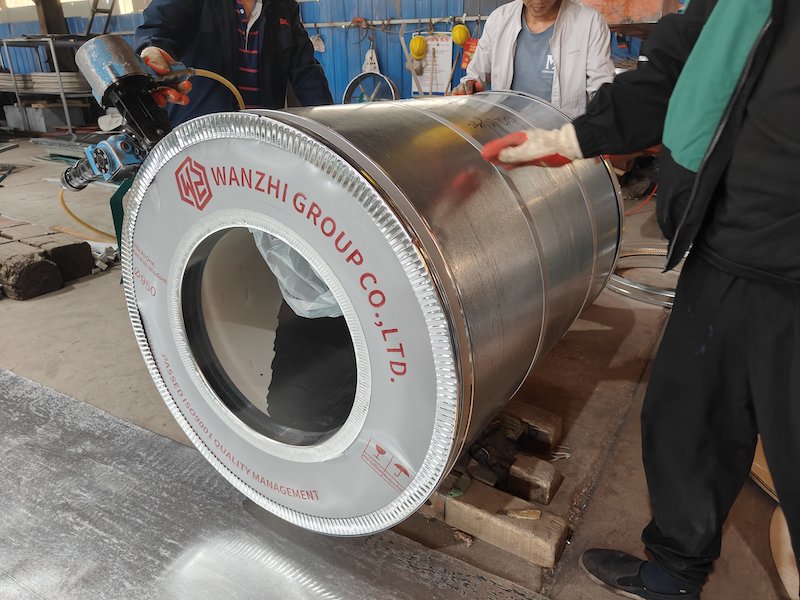

The packaging of color-coated steel coil is mainly divided into simple packaging, standard export packaging and special packaging.

Simple packaging is suitable for short-distance transportation, and its outer layer is protected by waterproof kraft paper, which has simple protective performance, but its price is low and the cost is low.

The outer surface of the standard export packaging is wrapped in waterproof kraft paper and galvanized iron, and reinforced with steel wire. Used for long-distance transportation and container transportation. It can better protect the surface of the color coated steel coil, and the waterproof effect is better. This kind of packaging is also the most widely used.

Special packaging includes vertical packaging or packaging according to customer requirements. This packaging method can calculate the price according to the packaging cost. Vertical packaging is rolled up with the heart and fixed to a wooden tray at the bottom. This packaging method can maximize the protection of the steel coil from the influence of external forces, but the packaging cost and labor cost are high.

Coil Product packaging case

At Wanzhi, before shipping customers ‘products, we will strictly package customers’ products according to the standard packaging plan to ensure that the transportation process is not damaged and allow customers to receive satisfactory products.

This is our real packing case:

Wanzhi PPGI

Wanzhi Steel is a wholesale PPGI steel supplier in China, which has its own factory. At our factory, we have 3 color coating lines, with an annual production capacity of 320,000 tons. There are also two galvanizing lines with an annual production capacity of 350,000 tons. Besides, there are sets of rolling equipment with different designs, shearing lines, etc. to meet different needs for plain or corrugated pre-painted galvanized steel sheets.

Welcome to contact us to visit our factory online or on-site.

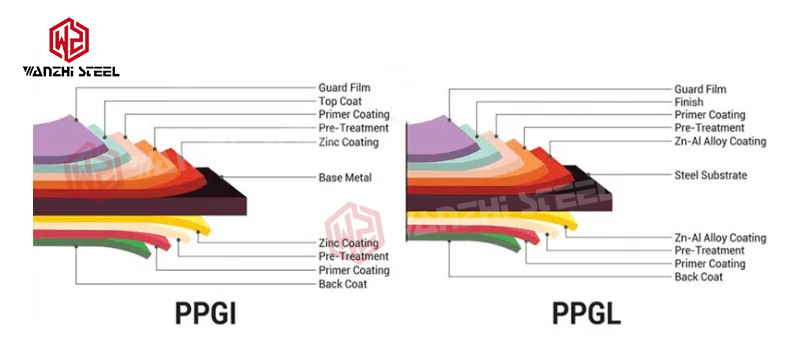

Differences Between PPGI And PPGL

The main difference between PPGI and PPGL is their material and use.

PPGI stands for galvanized color coated steel plate, which is a steel plate that is galvanized and coated with a color coating. This material is widely used in construction, home appliances, automobiles and other fields, and is favored for its good anti-corrosion and decorative properties.

PPGL refers to aluminum-zinc coated steel plate, which is treated by aluminum-zinc plated and coated with a color coating. Compared to PPGI, PPGL has higher corrosion resistance and coating adhesion and is suitable for more harsh environmental conditions, such as Marine climates or high salinity areas.