stainless steel Etched plate

What is stainless steel etched plate?

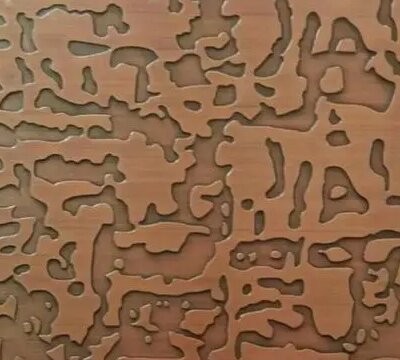

Stainless steel etched plate is to etch various patterns on the surface of stainless steel by chemical methods. With 8K mirror plate, brushed plate, sandblasted plate as the substrate, after etching, the surface of the object is deeply processed. Stainless steel etching plate can be processed with various complex processes such as local and grain, brushing, gold inlay, local titanium, etc., so that the stainless steel etching plate can achieve the effect of light and dark patterns and colorful colors.

Decorative etched plate

Stainless steel etched plate

Stainless steel etching is a metal etching process that uses corrosive metals to etch complex precision parts on stainless steel. This process is favored by modern metal processing because of its high precision and low failure rate.

The process of stainless steel etched plate

Stainless steel plate → degreasing → washing → drying → screen printing → drying → water immersion → etching pattern leaf (sheet) washing → ink removal → washing → polishing → washing → coloring → washing leaf (sheet) hardening treatment → sealing treatment → washing leaf (sheet) drying → inspection → product.

The principle of stainless steel etching

The strong oxidizing property of ferric chloride causes the surface of stainless steel to corrode, and the trivalent iron element turns into a relatively stable iron element. The specific production process is: first apply an anti-corrosion layer on the surface of the stainless steel to protect the part that needs protection, put it in a pipe sprayed with ferric chloride, and then wash off the anti-corrosion layer after corrosion, and the pattern will be formed.

Introduction to etching types

- Photosensitive etching: Using the principle of photosensitivity, the stainless steel plate coated with photoresist is exposed, developed and other steps are performed to form the desired pattern before etching. This method is suitable for mass production and high-precision pattern production.

- Silk screen etching: Print ink on the stainless steel plate through silk screen printing technology, and then etch it. This method is simple to operate and low in cost, suitable for small and medium-sized batch production.

- Titanium stripping etching: A layer of titanium metal film is first covered on the surface of the stainless steel plate, and then printed and etched. Titanium stripping etching can produce more delicate and complex pattern effects, but the cost is relatively high.

Irregular texture

Regular texture

Advantages of Metal Etching Stainless Steel

Low Setup Costs – Inexpensive flexible tools can be produced in a matter of hours compared to expensive hard tools with long lead times.

Burr and Stress Free – Parts are free of burrs or structural deformations. Chemical etching of stainless steel maintains smooth surfaces, precise edges and low tolerances.

Unaltered Metal Properties – Stainless steel parts will retain their toughness, hardness and functional properties.

Complex and Precision Designs – Metal photolithography etching is the fastest and most reliable method to achieve precision on small or high volume part features.

Rapid Prototyping – Low cost flexible tools easily speed up low volume prototyping. Design changes are also simple and cost effective.

Application of Stainless Steel Etched Plate

Stainless steel etching plates have a wide range of uses, mainly including decoration, industrial and special application fields.

Decoration field: Stainless steel etched plates are widely used in the decoration field because of their exquisite patterns and diverse color options. In the decoration of high-end places such as star-rated hotels, KTVs, large shopping malls and high-end entertainment venues, stainless steel etched plates can provide unique decorative effects and increase the beauty and artistic sense of the space. In addition, stainless steel etched plates can also be customized according to customer drawings and requirements to meet personalized decoration needs.

Industrial field: Stainless steel etched plates are also widely used in the industrial field, including but not limited to automotive mechanical parts, gaskets and spacer washers, high-performance sealing gaskets, filter meshes, and electric vehicle battery cells. These applications have high requirements for the wear resistance and scratch resistance of the material. Stainless steel etched plates have become an ideal choice for these fields due to their high durability and excellent physical properties.

Special application areas: Stainless steel etched plates are also used for carriage panels, hall wall panels, ceilings, signs, door and window decorations, etc. These applications not only require the beauty and durability of the material, but also require the ability to adapt to various environmental conditions. Stainless steel etched plates can meet the needs of these special applications due to their excellent corrosion resistance and wear resistance.

Stainless Steel Etched Plate Supplier

We can manufacture components to your exact specifications, whether they are sophisticated or rugged. With endless customization possibilities, our stainless steel etching process maintains the integrity of the stainless steel, corrosion resistance, ensuring long-lasting durability and suitability for a variety of applications.

Wanzhi Steel is a well-known stainless steel sheet manufacturer and stainless steel sheet supplier, providing excellent customer service and high-quality stainless steel sheets. If you have stainless steel sheet needs, please feel free to contact us.