Steel Profiles

What Is Steel Profiles ?

Steel profiles are metal materials made from steel that is formed by rolling, stretching or pressing. It is with specific cross-sectional shapes and sizes. These shapes have the same cross-section throughout their length. Steel sections are commonly used to reinforce concrete or building structures, helping to improve strength. It is a general term for hot-rolled steel plates, steel sections, steel pipes, and cold-formed thin-walled steel sections.

Classification of steel profiles

Profiles can be divided into hot-rolled profiles, cold-formed profiles, cold-rolled profiles, cold drawn profiles, extruded profiles, forged profiles, hot bent steel, welded profiles, and special rolled profiles according to their production methods.

Hot rolling profiles

The main method of producing profiles today is hot rolling; Because hot rolling has the advantages of large production scale, high production efficiency, low energy consumption, and low product cost.

Cold rolled and Cold drawn profiles

For profiles with high requirements for dimensional accuracy, surface roughness, and mechanical properties, cold rolling is used to produce cold-rolled profiles and cold drawing is used to produce cold drawn profiles. Cold drawn and cold-rolled profiles can not only be used as components for special purposes, but also as alternatives to hot-rolled profiles.

Cold formed profiles

The cold formed profiles are profiles produced by bending plates and strips at room temperature. Due to the cold bending deformation, the metal strength is significantly improved. The cold bending method can produce thin-walled profiles and complex section profiles that cannot be produced by hot rolling. Therefore, replacing hot rolling profiles with cold bending profiles can generally save 20% to 50% of metal materials.

Channel steel

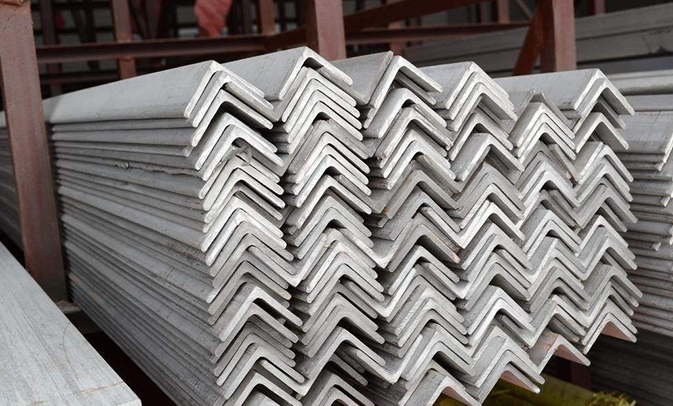

Angle steel

Extruded profiles

Using extrusion method to produce profiles, the extruded parts have a stronger three-dimensional compressive stress state than the rolling method during production, allowing the metal to exert its maximum plasticity and process difficult to deform metals. By changing the shape of the extrusion die hole on the same device, it is possible to produce profiles with extremely complex and variable cross-sectional shapes that are difficult to produce using rolling methods.

Extrusion production has great flexibility and is very suitable for small batch and multi variety production; The product has precise dimensions and high surface quality, which is between hot-rolled and cold-rolled profiles. There are many varieties of extruded profiles, mainly non-ferrous metal alloy profiles, especially aluminum profiles. The steel produced by extrusion method is mostly a small batch, low plasticity, and difficult to deform high alloy steel pipe with irregular profiles.

Welded profiles

Welded profiles are profiles made by welding straightened plates together. Using welding method to produce profiles can not only save metal, but also produce extra large profiles. With the development of sheet metal production, the proportion of welded profiles will also increase day by day.

Hot bent profiles

Hot bent profiles are profiles formed by bending thin-walled shaped sheets as raw materials in a sequential arrangement of several hot bending forming frames, under the residual heat state after hot rolling. This production method is a combination of hot rolling forming and hot bending forming, which first rolls the billet into thin-walled shaped plates with uneven thickness and sharp corners at several points on a hot rolling mill, and then continuously bends them into open, semi closed shaped materials and closed profiles.

Steel frame

Steel Profiles Application

The hot bending method can produce profiles that cannot be produced by hot rolling or cold bending methods. The mechanical properties of the profile section are uniform and consistent throughout, with no micro cracks or thickness reduction at the bending point. Hot bent profiles can save 7% to 9% of metal compared to cold-formed profiles, and 27% to 59% of metal compared to hot-rolled profiles.

Forging profiles

Forging profiles are profiles formed from metal under the reciprocating impact force of a forging hammer or the pressure of a press. Typical products include round bars, cakes, variable cross-section and irregular cross-section profiles.

Special rolled profiles

Special rolled profiles refer to longitudinal rolled section steel, cross wedge rolled axisymmetric circular section profiles, oblique rolled and cross rolled profiles.

The characteristic of periodic section steel is that the shape and size of the section change periodically along the length direction. The difference between the rolling of periodic section steel and ordinary section steel lies in the fact that the forming rolls have hole patterns with varying cross-sections along the circumferential direction. Therefore, during the rolling process, parameters such as the amount of reduction, bite angle, forward sliding, width expansion, and metal pressure on the rolling rolls along the length direction of the rolled piece also vary periodically.

Wedge cross rolling profiles are profiles rolled using the wedge cross rolling method.

Diagonal rolled profiles are profiles produced using the hole type oblique rolling method.

Angle steel

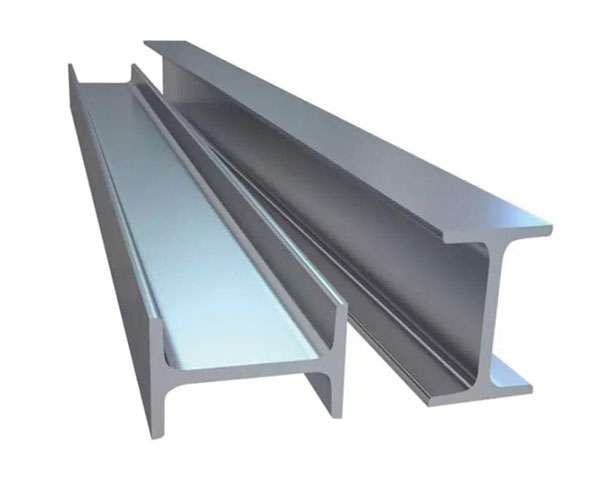

H-beam steel

When producing profiles by cross rolling, the metal undergoes plastic deformation in the gaps between the rolling rolls that rotate in the same direction and have parallel centerlines. The profiles produced by this method are called cross rolled profiles.

Characteristics of steel profiles production

(1) There are many varieties and specifications of products. At present, there are more than 10,000 varieties and specifications of profiles. Except for a few special rolling mills that produce special products, most profile rolling mills produce multiple varieties and specifications.

(2) There are large differences in cross-sectional shapes. Among profile products, except for square, round and flat steel, which have simple cross-sectional shapes and little difference, most complex cross-sectional profiles (such as channel steel, I-beam, Z-beam, rail, etc.) not only have complex cross-sectional shapes, but also have large differences in cross-sectional shapes.

(3) There are various mill structures and layout types. In terms of structural types, there are two-roll mills, three-roll open mills, four-roll universal mills, multi-roll hole mills, Y-type mills, 450 mills and cantilever mills. In terms of mill layout, there are horizontal mills, row mills, chessboard mills, double-layer mills, semi-continuous mills, continuous mills and compact mills.

Steel profiles application areas

Construction field

In the construction field, steel profiles are widely used, mainly for making frames, beams, columns, brackets and other parts. Steel profiles can be selected in different models and specifications according to the required strength and rigidity. At the same time, due to its highly reliable strength and toughness, it can effectively improve the seismic resistance and safety of buildings.

Mechanical manufacturing field

In the field of mechanical manufacturing, steel profiles are used to make various mechanical parts. Such as frames, brackets, bearings, shafts, gears, etc. Due to its high strength and rigidity, it can improve the working efficiency and reliability of mechanical equipment.

Bridge construction

Steel profiles are mainly used in bridge construction for the bearing and supporting parts of bridge structures. Such as piers, bridge decks, beams, etc. The high strength and corrosion resistance of steel make it widely used in the construction of large-span and difficult bridges.

Transportation field

Steel profiles are also widely used in the field of transportation, such as car bodies, train tracks, ships and aircraft parts. The high strength, lightness and easy manufacturing of steel make it an ideal material in the automotive and transportation fields.

In short, steel profiles are a cost-effective building material with a wide range of applications. They have the advantages of high strength, corrosion resistance, and excellent toughness, and can provide reliable support and guarantee for all walks of life.

Steel profiles manufacturers

If you need more information about steel profiles, Wanzhi is one of the leading companies in the steel and metal fabrication industry. Please contact us and we can provide you with friendly and professional service and advice.