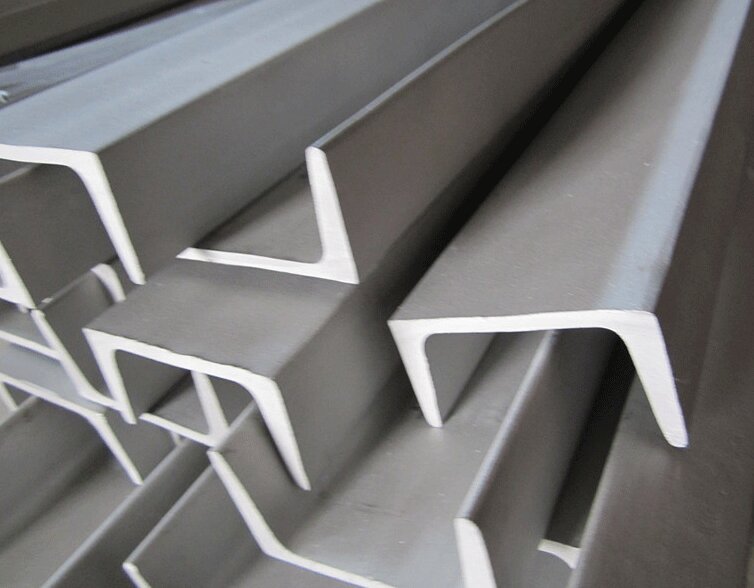

Channel steel

What is channel steel?

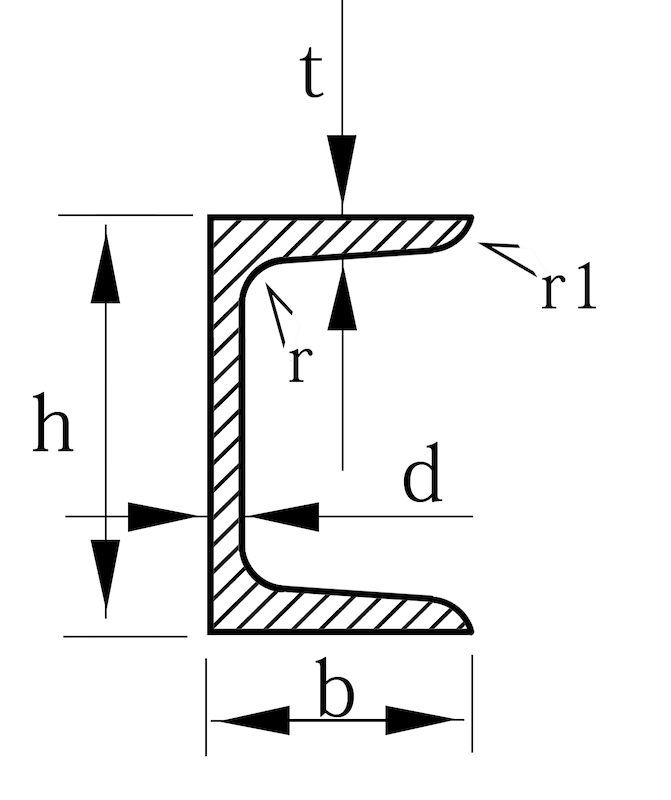

Channel steel is a long steel strip with a groove-shaped cross section. It is a carbon structural steel for construction and machinery. It is a steel section with a complex cross section and a groove-shaped cross section. This design not only gives the channel steel good bending strength and bearing capacity, but also facilitates connection and fixing with other components, improving the overall stability of the structure.

Its specifications are expressed as h*b*d; it means a channel steel with a waist height of h mm, a leg width of b mm, and a waist thickness of d mm, or (h/10)# channel steel. If there are several different leg widths and waist thicknesses for channels with the same waist height, abc should be added to the right of the model to distinguish them, such as 25#a 25#b 25#c, etc.

Channel steel structure

Channel steel parameter

| Item | Product parameter |

| Product Name | Channel steel |

| Common Material | Q235/BQ235C/Q235D/Q345B/Q345C |

| Material Type | Aluminum/Mild steel/Stainless steel |

| length | 5-12m,5-19m,6-19m |

| Model | 5# – 40# |

| Standard | ISO/JIS/GB/ASTM/DIN |

| MOQ | 10tons |

| Application | Building structures, vehicle manufacturing, other industrial structures and fixed cabinets |

| Production Capacity | 10000 Tons per Month |

| Package | Standard Export Package |

Ordinary channel steel specifications

| Gauge / Model | Dimensions | Theoretical Weight (kg/m) | Interface area (cm²) | ||

| h (mm) | b (mm) | d (mm) | |||

| 6.5 | 65 | 40 | 4.8 | 6.709 | – |

| 8 | 80 | 43 | 5 | 8.045 | 10.248 |

| 10 | 100 | 48 | 5.3 | 10.007 | 12.748 |

| 12 | 120 | 53 | 5.5 | 12.059 | – |

| 12.6 | 126 | 53 | 5.5 | 12.318 | 15.692 |

| 14#A | 140 | 58 | 6 | 14.535 | 18.516 |

| 14#B | 140 | 60 | 8 | 16.733 | 21.316 |

| 16#A | 160 | 63 | 6.5 | 17.24 | 21.962 |

| 16#B | 160 | 65 | 8.5 | 19.754 | 25.162 |

| 18#A | 180 | 68 | 7 | 20.174 | 25.699 |

| 18#B | 180 | 70 | 9 | 23 | 29.299 |

| 20#A | 200 | 73 | 7 | 22.637 | 28.837 |

| 20#B | 200 | 75 | 9 | 25.777 | 32.837 |

| 22#A | 220 | 77 | 7 | 24.999 | 31.846 |

| 22#B | 220 | 79 | 9 | 28.453 | 36.246 |

| 25#A | 250 | 78 | 7 | 27.41 | 34.917 |

| 25#B | 250 | 80 | 9 | 31.335 | 39.917 |

| 25#C | 250 | 82 | 11 | 35.26 | 44.917 |

| 28#A | 280 | 82 | 7.5 | 31.427 | 40.034 |

| 28#B | 280 | 84 | 9.5 | 35.832 | 45.634 |

| 28#C | 280 | 86 | 11.5 | 40.219 | 51.234 |

Channel steel production process

Channel steel production mainly involves raw material preparation, heating, rolling, cooling, finishing and other processes.

The raw materials are usually high-quality iron ore smelted in a blast furnace to obtain molten iron, and then steel-making in a converter or electric furnace to obtain qualified steel.

After the steel is heated to a suitable temperature in a heating furnace, it enters the rolling mill for continuous rolling to form the required channel steel cross-sectional shape.

After rolling, the channel steel needs to be cooled to improve its hardness and strength.

Finally, through finishing processes such as straightening, cutting, and inspection, ensure that the quality of the channel steel meets the standards.

Mild steel channel steel

Hot rolled channel steel

Classification of channel steel

Channel steel is divided into ordinary channel steel and light channel steel. There are two major categories: ordinary carbon structural steel and low-alloy high-strength structural steel. The former is mainly used for general building structures, while the latter is widely used in engineering projects that require higher strength and toughness. The specifications of hot-rolled ordinary channel steel are 5-40#. The specifications of hot-rolled variable channel steel supplied by agreement between the supply and demand parties are 6.5-30#.

Extra thick channel steel

Stainless channel steel

Channel steel can also be divided into multiple specifications according to different cross-sectional sizes to meet different engineering needs. According to the shape, it can be divided into: cold-bent equilateral channel steel, cold-bent unequal-sided channel steel, cold-bent inner-curled channel steel, and cold-bent outer-curled channel steel.

Advantages of Steel Channels

Lightweight: Channel steel has a low density and is light in weight, making it easy to transport and install.

High strength: Channel steel is made of high-quality steel and has high strength and rigidity.

Low cost: Compared with other structural materials, the production cost of channel steel is low and it is economical in engineering projects.

Diverse dimensions and specifications: Channel steel has a variety of dimensions and specifications to meet the needs of different projects.

Hot Rolled

Mild Steel

Galvanized

Application fields of channel steel

Channel steel plays a pivotal role in the construction industry due to its unique properties and wide applicability.

In terms of building structures, channel steel is often used to support and connect heavy structures such as steel structure workshops, bridges, towers, crane track brackets, etc. Its good bending resistance and easy processing make channel steel an ideal choice for making steel beams, steel columns and other components.

Channel steel is also widely used in machinery manufacturing, vehicle manufacturing, shipbuilding and other fields. In machinery manufacturing, channel steel is often used to make heavy parts such as machine tool beds and workbenches. In vehicle and shipbuilding, channel steel is used to build key structures such as vehicle frames and hull frames. Channel steel is also often used in conjunction with I-beams.

Channel Steel Supplier

Wanzhi Steel is a leading manufacturer and supplier of channel steel,dedicated to providing high-quality steel products for various industries.With a commitment to excellence,we ensure our channel steel meets the strictest standards for durability and reliability.

If you have any needs for channel steel or other steel products, please contact us.