304L Stainless Steel is a low-carbon version of the widely used 304 stainless steel. It has excellent corrosion resistance, good welding performance, and outstanding processing and forming ability, and is widely used in industries such as chemical, food processing, building structures, and water treatment.

The letter ‘L’ represents Low Carbon, which significantly reduces the risk of intergranular corrosion after welding, making it particularly suitable for welding structures and equipment manufacturing.

Chemical composition of SS 304L

304L belongs to the austenitic stainless steel series, with typical chemical compositions including:

Chromium (Cr): 18-20%

Nickel (Ni): 8-12%

Carbon (C): ≤ 0.03%

Compared with standard 304 stainless steel, lower carbon content can effectively reduce carbide precipitation during welding, thereby improving long-term corrosion resistance.

Main performance characteristics

Excellent corrosion resistance performance

SS 304L has good resistance to oxidative environments, humid air, and various weakly corrosive chemical media, and is suitable for water environments, food contact environments, and various organic and inorganic media environments.

Excellent welding performance

Due to its low carbon content, 304L stainless steel usually does not require heat treatment after welding, and can effectively reduce the risk of intergranular corrosion in the heat affected zone, making it very suitable for welding pipelines, storage tanks, and structural components.

Good processing and forming performance

304L is easy to bend, cut, punch, and deeply stretch, and is widely used in the manufacturing of various customized stainless steel parts and formed products.

Good low-temperature toughness

Even in low-temperature environments, 304L stainless steel can maintain good toughness and mechanical properties, and is less prone to brittle cracking.

Application areas of SS 304L

Chemical equipment – storage tanks, pipelines, heat exchangers

Food and Beverage Industry – Processing Equipment, Storage Containers

Water treatment system – pipelines, connectors, water tanks

Architecture and Decoration Engineering – Structural Components, Decorative Components

Pharmaceutical Equipment – Sanitary Processing System

Limitations of 304L Stainless Steel

Although 304L has excellent comprehensive corrosion resistance, it is not suitable for high chloride ion environments such as seawater or coastal high salt environments. In such working conditions, it is recommended to use SS 316L for better resistance to pitting and crevice corrosion.

The difference between 304 and 304L stainless steel

The two have similar corrosion resistance and overall performance, but 304L stainless steel is more suitable for welding applications due to its lower carbon content.

If the project involves a large amount of welding or thick walled structures, 304L stainless steel is usually preferred.

Common forms of supply

Wanzhi Steel can provide various specifications of 304L stainless steel products:

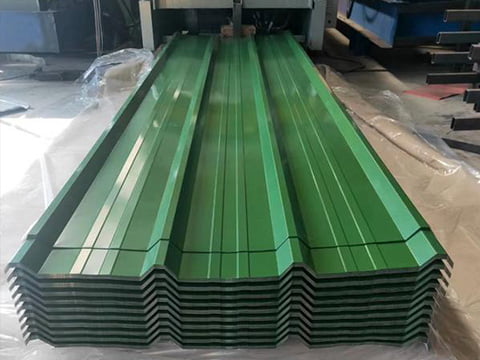

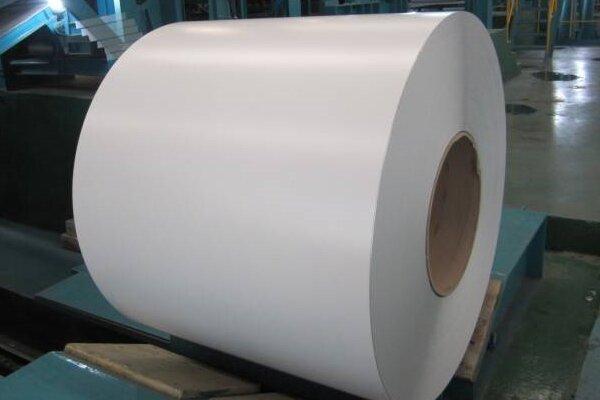

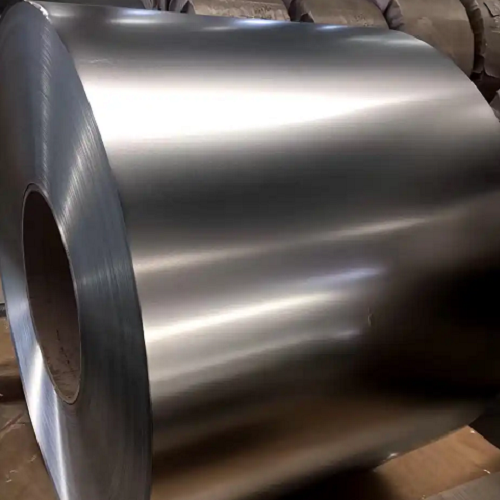

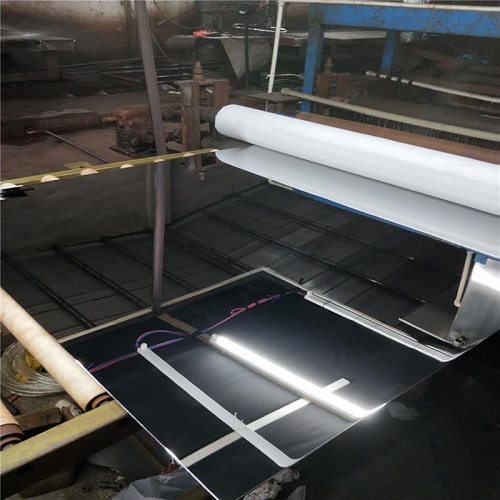

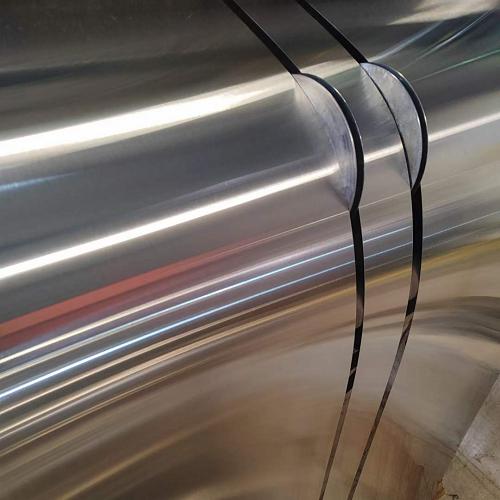

1. Stainless steel plate/stainless steel coil

2. Stainless steel strip

3. Stainless steel pipes/fittings (seamless and welded pipes)

4. Stainless steel rod

We can customize the size and surface treatment status according to customer requirements.

304L Stainless Steel Supplier – Wanzhi Steel

As a professional supplier of SS 304L, Wanzhi Steel can provide high-quality materials that meet international standards, strict quality control, and diverse specification choices. Whether you need stainless steel plates, pipes or other customized processing products, Wanzhi can do its best to provide them for you. Welcome to inquire and obtain a corrosion-resistant material solution that combines cost-effectiveness and reliability.