Electrostatic spraying color plate has the following advantages:

1. High spraying efficiency: electrostatic spraying uses electrostatic action to charge the coating particles, and then sprays the charged coating particles to the object surface with opposite charge, so the painting task can be completed quickly and the production cost can be reduced.

2. Save paint: electrostatic spraying can effectively spray paint on the surface of the workpiece, will not produce spatter and waste like traditional spraying, so you can save the amount of paint.

3. Environmental protection: in the process of electrostatic spraying, airless nozzles are used to reduce the pollution of aerosol to the surrounding environment and help to protect the ecological environment.

4. High spraying quality: electrostatic spraying can complete multi-coating in a short time, the coating quality is more uniform, the surface is smooth and delicate, and the quality of the product is improved.

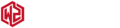

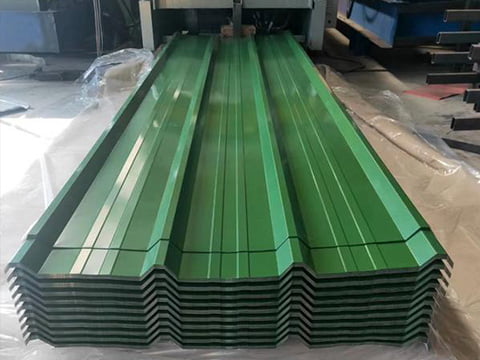

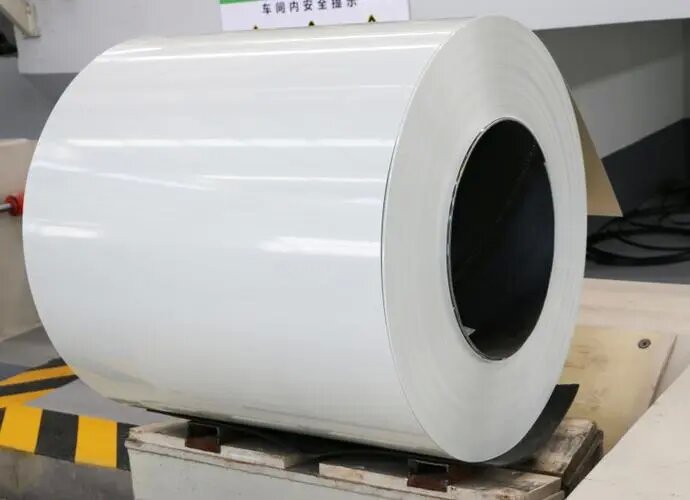

Electrostatic color coating is sprayed on the steel plate by electrostatic adsorption coating process and baked and solidified. The coating time is long, the front and back can be coated, the thickness of one-sided coating can reach 120 μ m, and it has good processability, and the T-bending property can reach 0T (180 degree unpainted bending). Because the paint does not contain solvents and has zero VOC emissions in the production process, the green environmental protection production is really realized.

Because of its good anti-ultraviolet, corrosion resistance and excellent processing performance, the service life of electrostatic spraying color plate is 2-3 times longer than that of ordinary color plate in normal use environment. it is widely used in building metal enclosure, purification workshop, fire door, household appliances, decoration and other fields.

Summary:

To sum up, electrostatic spraying has the advantages of high spraying efficiency, paint saving and environmental protection, but the construction conditions are more stringent, it is easy to produce electrostatic sparks and the scope of application is limited, so it needs to be selected according to the specific conditions.