Introduction and Application of Aluminum sheets & coils

Aluminum sheets & coils have many excellent properties, such as low density, high specific strength, good corrosion resistance, easy processing and beautiful surface, and can be oxidized and colored or coated with decorative coatings.

Aluminum was first discovered by Danish scientist H.C.Oersted in 1825, and has a history of more than 160 years. Aluminum sheets & coils is widely used in many fields, including: 1. Lighting fixtures; 2. Solar reflectors; 3. Building exteriors; 4. Interior decoration: suspended ceilings, walls, etc.; 5. Furniture, cabinets; 6. Elevators; 7. Signs, nameplates, bags; 8. Car interior and exterior decoration; 9. Interior decorations: such as photo frames; 10. Household appliances: refrigerators, microwave ovens, audio equipment, etc.; 11. Aerospace and military, such as China’s large aircraft manufacturing, Shenzhou spacecraft series, satellites, etc.; 12. Mechanical parts manufacturing and processing; 13. Mold manufacturing; 14. Chemical/insulation pipe coating; 15. High-quality ship plates, etc.

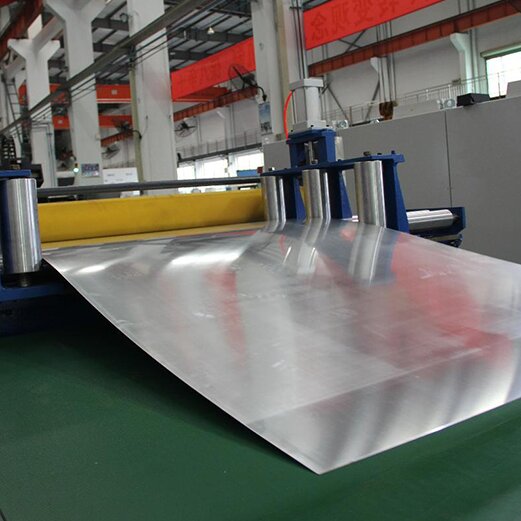

Aluminum sheets

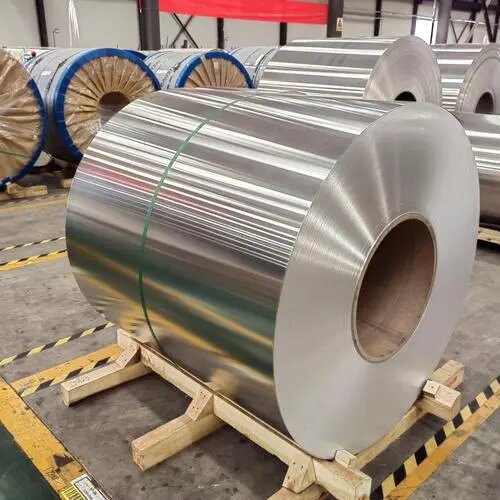

Spot aluminum coils

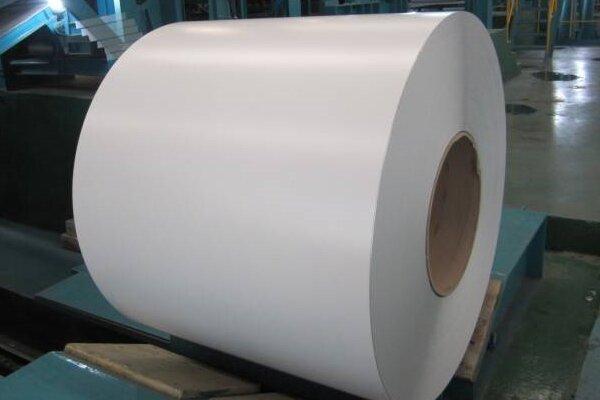

Classification of Aluminum sheets & coils

There are many aluminum sheets & coils production enterprises in my country, and the production technology has caught up with developed countries. According to the different metal elements contained in aluminum coils, aluminum coils can be roughly divided into 9 categories, that is, they can be divided into 9 series, among which 1, 3, 5, 6, and 7 series aluminum and aluminum alloys are the main ones. Other series are rarely used in actual use. The following is a brief introduction step by step:

1000 series, industrial pure aluminum [Al]

The 1000 series is also known as pure aluminum. Among all the series, the 1000 series has the highest aluminum content. The purity can reach more than 99.00%. Since it does not contain other technical elements, the production process is relatively simple and the price is relatively cheap. It is the most commonly used series in conventional industries. Most of the 1050 and 1060 series are circulating on the market.

The 1000 series aluminum materials determine the minimum aluminum content of this series based on the last two Arabic numerals. For example, the last two Arabic numerals of the 1050 series are 50. According to the international brand naming principle, the aluminum content must reach more than 99.5% to be a qualified product. China’s aluminum alloy technical standard (GB/T3880-2006) also clearly stipulates that the aluminum content of 1050 reaches 99.5%. For the same reason, the aluminum content of 1060 series aluminum materials must reach more than 99.6%.

2000 series, aluminum-copper alloy [Al-Cu]

Its representatives include 2A16 (LY16) and 2A06 (LY6. The characteristics of 2000 series aluminum are high hardness, among which copper content is the highest, about 3-5%. 2000 series aluminum belongs to aviation aluminum and is not often used in conventional industries. There are few manufacturers producing 2000 series aluminum in China. However, with the development of China’s aerospace industry, the production technology of 2000 series aluminum will be further improved.

3000 series, aluminum-manganese alloy [Al-Mn]

The most common ones are 3003 and 3A21. It can also be called rust-proof aluminum. China’s 3000 series aluminum plate production process is relatively excellent. The 3000 series aluminum plate is mainly composed of manganese elements. The content is between 1.0-1.5. It is a series with good rust-proof function. It is generally used in humid environments such as air conditioners, refrigerators, and car bottoms. The price is higher than the 1000 series. It is a more commonly used alloy series.

4000 series, aluminum silicon alloy [Al-Si]

The 4000 series aluminum materials are of high silicon content, represented by 4A01. Usually the silicon content is between 4.5-6.0%. They are used for building materials, mechanical parts, forging materials, welding materials; low melting point, good corrosion resistance. Product description: Heat-resistant and wear-resistant

Aluminum window frame

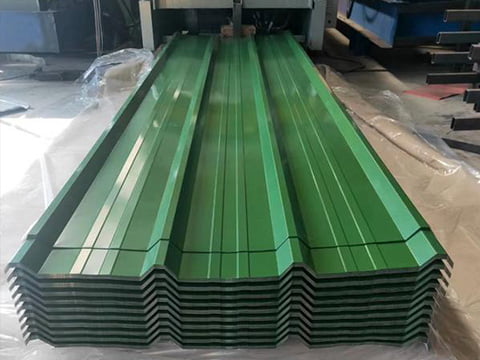

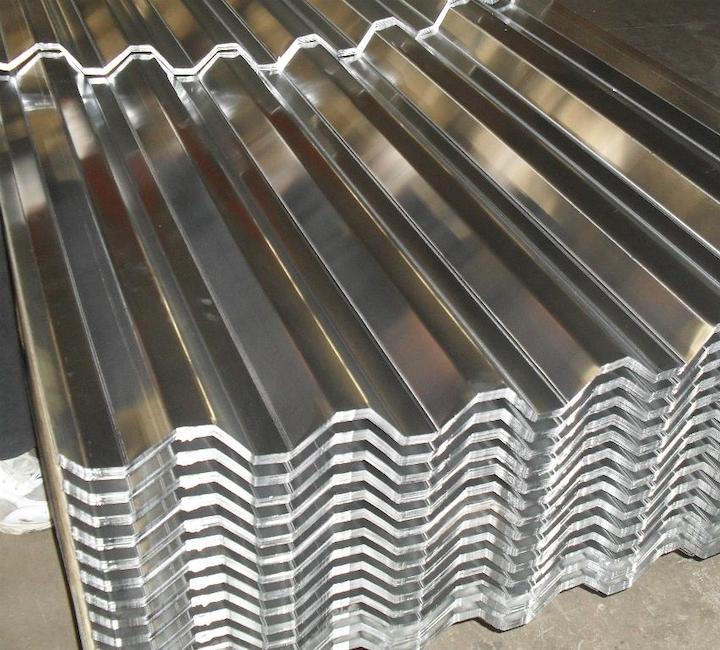

Aluminum roof panels

5000 series, aluminum-magnesium alloy [Al-Mg]

Its representatives include 5052, 5005, 5083, and 5A05 series. 5000 series aluminum is a commonly used alloy aluminum series. The main element is magnesium, and the magnesium content is between 3-5%. It can also be called aluminum-magnesium alloy.

The main characteristics are low density, high tensile strength, and high elongation. The weight of aluminum-magnesium alloy is lower than other series under the same area, so it is often used in aviation, such as aircraft fuel tanks. It is also widely used in conventional industries. The processing technology is continuous casting and rolling. It belongs to the hot-rolled aluminum plate series, so it can be oxidized and deep processed. In China, 5000 series aluminum is one of the more mature aluminum plate series.

6000 series, aluminum-magnesium-silicon alloy [Al-Mg-Si]

The representative series is 6061, which mainly contains two elements, magnesium and silicon, so it concentrates the advantages of the 4000 series and the 5000 series. 6061 is a cold-treated aluminum forging product, suitable for applications with high requirements for corrosion resistance and oxidation resistance. It has good usability, excellent interface characteristics, easy coating, and good processability. It can be used in low-pressure weapons and aircraft joints.

General characteristics of 6061: excellent interface characteristics, easy coating, high strength, good usability, and strong corrosion resistance.

Typical uses of 6061 aluminum: aircraft parts, camera parts, couplers, ship accessories and hardware, electronic accessories and joints, decorative or various hardware, hinge heads, magnetic heads, brake pistons, hydraulic pistons, electrical accessories, valves and valve parts.

7000 series, aluminum-zinc-magnesium-copper alloy [Al-Zn-Mg-Cu]

It mainly contains zinc, representing 7075. It also belongs to the aviation series, is an aluminum-magnesium-zinc-copper alloy, is a heat-treatable alloy, belongs to a super-hard aluminum alloy, and has good wear resistance. 7050 aluminum is stress-eliminated and will not deform or warp after processing. All super-large and super-thick 7075 aluminum materials are ultrasonically detected to ensure that there are no sand holes or impurities. 7075 aluminum has high thermal conductivity, which can shorten the molding time and improve work efficiency. The main feature is hardness. 7075 is a high-hardness, high-strength aluminum alloy, commonly used in the manufacture of aircraft structures and futures. It requires high-strength, high-corrosion resistance, high-stress structural parts, and mold manufacturing.

8000 series, other alloys

The more commonly used one is 8011, which belongs to other series. As far as I can remember, it is mainly used to make bottle caps. It is also used in radiators, and most of the applications are aluminum foil. It is not commonly used.

Aluminum Alloy Material

Aluminum Alloy Bars

9000 Series, Spare Series

It belongs to the backup series. With the development of science and technology, in order to cope with the emergence of aluminum plates containing other alloy elements, the International Aluminum Plate and Strip Federation specifically stated that the 9000 series is a backup series, waiting for another new variety to appear to fill the gap in the 9000 series.

Key points for purchasing Aluminum sheets & coils

Faced with a wide range of aluminum sheets & coils models, how to make the right choice? The following suggestions may help you:

- Clarify your needs: First, you must be clear about your usage requirements, including the required strength, corrosion resistance, formability and other performance requirements.

- Understand the market: Understand the market price, supply and quality differences of different types of aluminum coils in order to make the most cost-effective choice.

- Technical consultation: Communicate with professional suppliers or technicians to obtain more detailed technical parameters and recommended solutions.

- Sample testing: When conditions permit, conduct sample testing to verify whether the actual performance of the selected aluminum coil meets expectations.

- Pay attention to environmental protection: With the improvement of environmental awareness, it is also particularly important to choose aluminum coil products that meet environmental standards.

Conclusion

The selection and application of aluminum sheets & coils models is an indispensable part of metal processing and manufacturing. By deeply understanding the performance characteristics and application scenarios of various series of aluminum sheets & coils and making scientific and reasonable purchases based on actual needs, we can not only improve product quality and production efficiency, but also occupy a favorable position in the fierce market competition. In the future, with the advancement of science and technology and the upgrading of industry, aluminum sheets & coils materials will surely usher in a broader development space and application prospects.

It is particularly important to note that aluminum products are harmful to the human body. Aluminum can damage brain cells. Aluminum accumulates slowly in the human body. The toxicity it causes is slow and difficult to detect. However, once a toxic reaction of metabolic disorder occurs, the consequences are very serious.