Comparison Between PPGI and PPGL

PPGI and PPGL are two different coating technologies with certain differences in application and performance. PPGI is a technology that uses zinc as a matrix and coats a layer of color pigment on the zinc surface, which is suitable for lighter environmental conditions. PPGL, on the other hand, uses aluminum zinc as a matrix and coats a layer of color pigment on the aluminum zinc surface, which has better corrosion resistance and is suitable for harsh environmental conditions. This is the main difference between PPGI and PPGL, which will further affect their functions and applications.

PPGL sheet has better heat resistance than PPGI sheet. PPGL plate can withstand 315ºC. In addition, PPGL plates have better corrosion resistance than PPGI plates. This is because the dense aluminum layer prevents further erosion of the base metal.

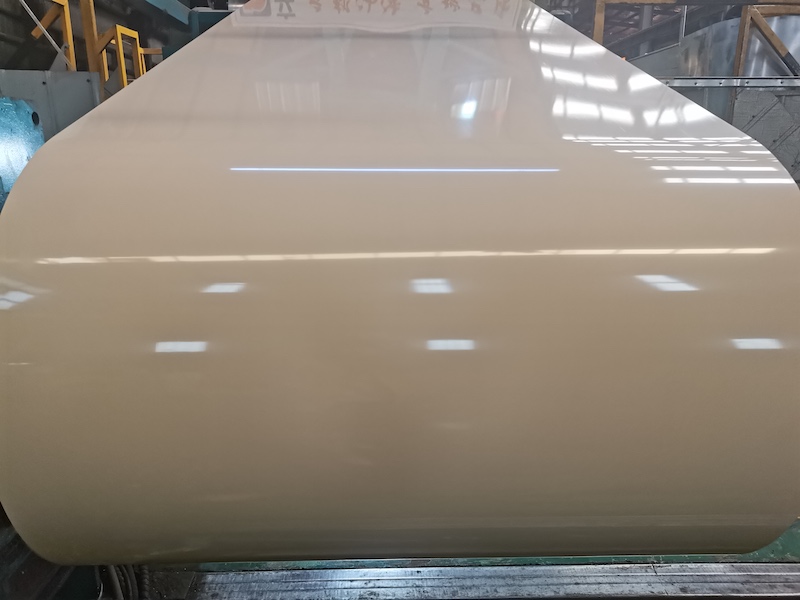

RAL Color Coated Steel

RAL 4006 PPGL

The advantage of PPGI is its color diversity, which can be adjusted as needed, and its price is low. However, the color pigment of galvanized color coating can only provide limited corrosion resistance, and the color may fade under harsh environmental conditions, and it cannot provide good corrosion resistance.

The advantage of PPGL is that its aluminum zinc has good corrosion resistance and conductivity, which can effectively resist the invasion of corrosive factors such as acid, alkali, and salt. The color pigment of galvanized color coating has better corrosion resistance and is not easy to fade. However, the price of PPGL is relatively high.

There are also certain differences in the production process of PPGI and PPGL. The PPGI production process is relatively simple, the process is not complicated, and the production cycle is short. The PPGL production process is complex, the process is cumbersome, and the production cycle is long.

PPGI and PPGL Price Comparison

Finally, it should be noted that the value and cost performance of PPGI and PPGL are different. Customers need to weigh the pros and cons according to their needs when choosing to ensure that the most suitable coating technology is selected.

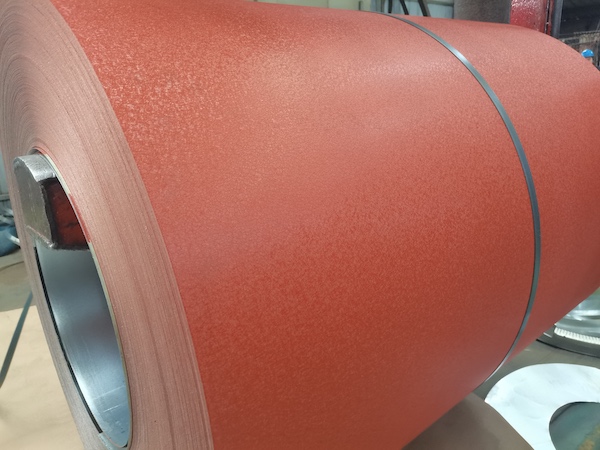

Orange Peel

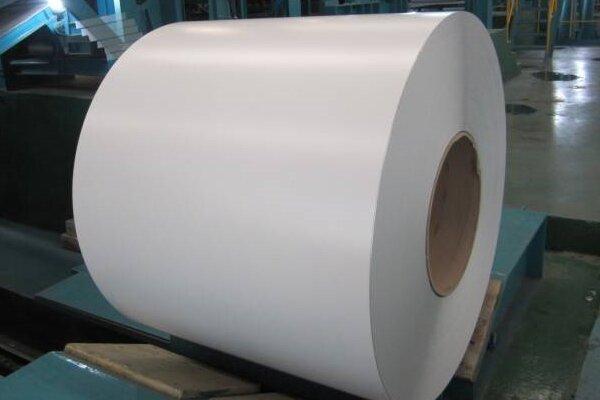

RAL 9003 PPGI

PPGI (Pre-coated Galvanized Steel Sheet) and PPGL (Pre-coated Galvalume Steel Sheet) are surface treated steels used in various industrial and architectural applications. Compared with major markets, the price of ppgi and ppgl are certain different. The price of ppgl will be higher than ppgi. Because PPGL has better corrosion resistance and longer service life, it is usually used in higher-end application scenarios, so its price is relatively high. In addition, PPGL can meet more personalized needs, which is one reason for its higher price. In contrast, although PPGI is lower in price, it is still widely used in some applications that do not require high corrosion resistance.

How to Choose PPGI and PPGL

Therefore, when choosing PPGI and PPGL, it is necessary to consider the place of use, environmental conditions, and customer needs. If it needs to be used in mild environmental conditions, has high color requirements, and is price sensitive, then PPGI is a good choice. However, if it needs to be used in harsh environmental conditions and needs to provide good corrosion resistance, then PPGL is a better choice.

Conclusion

In short, PPGI and PPGL are two different coating technologies with differences in application and performance. It is necessary to determine which coating technology to use based on the place of use, environmental conditions, and customer needs.

PPGI and PPGL Suppliers

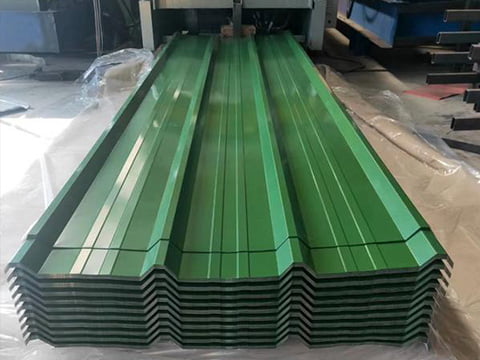

Color coated steel use

Color coated steel spot

There are many suppliers to choose from in the market. When selecting suppliers, we should pay attention to whether they are experienced, whether they can supply goods quickly, etc. Wanzhi Company is a good choice. We not only have an elite sales team, but also have our own factory in Shandong, China. Our factory has 3 color coating lines with an annual production capacity of 320000 tons. There are also two galvanizing lines with an annual production capacity of 350000 tons.

For your inquiry information, we will contact you as soon as possible. Looking forward to your inquiries, you can also visit our company and factories.