History and Uses of Color Coated Steel

Color coated steel products have been developed for nearly 100 years, and we can come into contact with color-coated steel products in many places where we live and work.

Color Coated Steel Development history

In 1927, the United States pioneered the production of organic coated steel plates

1936, the United States built its first production line

1954, Japan introduced American technology to produce single color-coated steel plates

1964, continuous color-coated steel plate production lines were put into operation, and many European countries began to produce color steel plates

1975, South Korea and China jointly began to produce color steel plates

1988, Wuhan Iron and Steel and Baosteel (1989) began to put color steel plate production lines into operation

Color Coated Steel Application

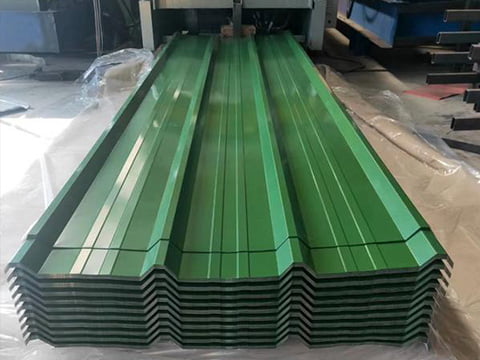

Color coated steel can be used in industrial plants, gymnasiums, airports, stations, flat-to-slope conversions, interior partitions, warehouses, elevators, curtain walls and other buildings.

What should you pay attention to when buying color coated steel?

There are three aspects to pay attention to when purchasing color coated steel: the substrate, the zinc layer, and the paint film.

1.Substrate

When purchasing color coated galvanized steel, the specific steel type is often considered according to the design requirements, because the steel type involves the building’s load-bearing weight, span and purlin distribution requirements.

Galvanized steel is divided into 30 kg (280MPa), 35 kg (340MPa), 40 kg (400MPa), 45 kg (440MPa), 50 kg (490MPa), 55 kg (MPa) and full hard plate according to the tensile strength of the structure. Of course, due to the differences in standards in many countries, there are also different classifications.

The strength of color steel depends on the base material, so its strength can refer to the situation of the base material. Enterprises classify it according to CQ, DQ, HSS, and FH, but the final choice depends on the design requirements, especially the corresponding yield strength, tensile strength, elongation and other indicators.

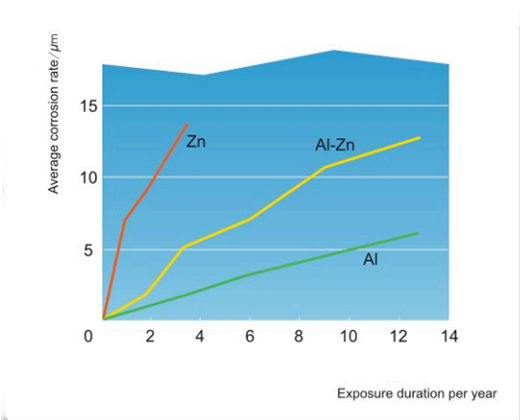

Due to the different performances of zinc and aluminum under acidic and alkaline conditions, it is recommended to use aluminum-zinc-coated base color coated steel under acidic conditions (PH=3~7), and galvanized base color-coated steel under alkaline conditions (PH7~13), but regardless of the acid or alkaline environment, the service life of the product will definitely be affected.

In short, when purchasing color coated galvanized steel, we should pay attention to the strength of the material, and the design should also consider the balance between safety and economy.

2.Plating

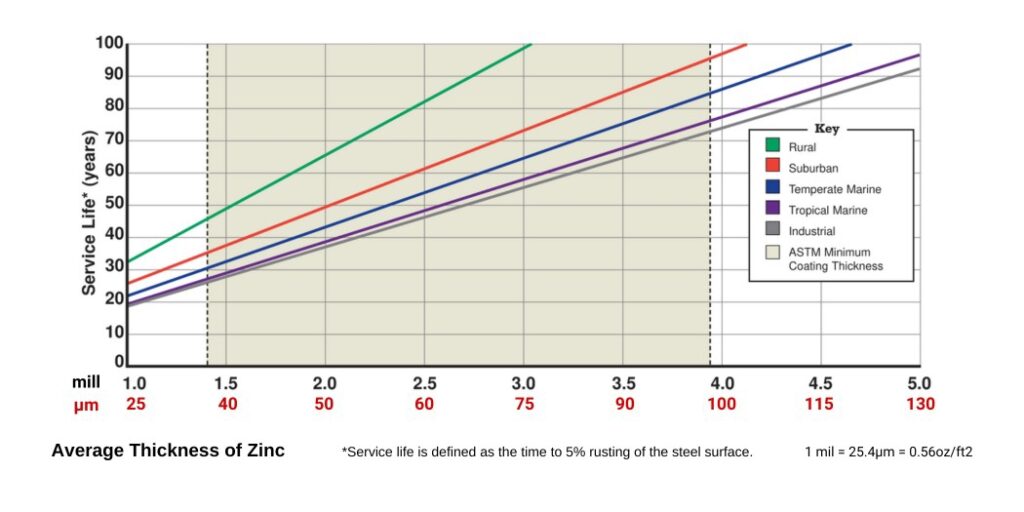

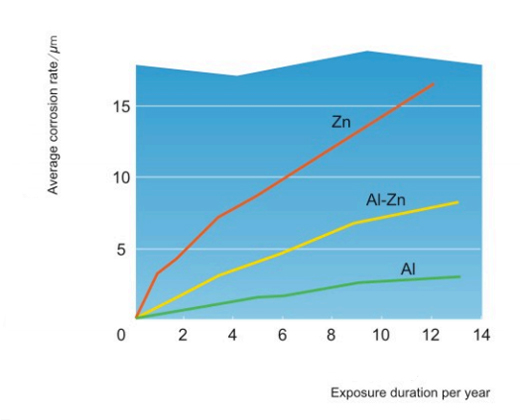

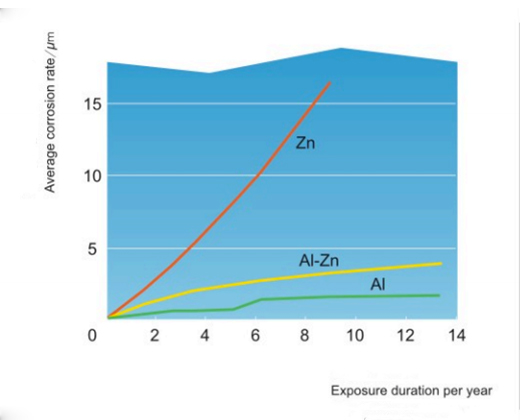

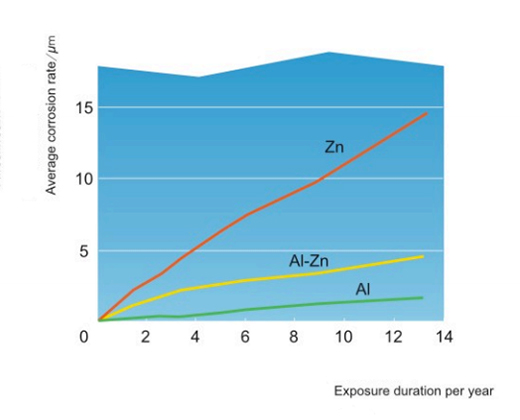

The thickness of the coating is the most important guarantee for corrosion resistance. The thicker the coating, the better the corrosion resistance. This has been proven by many accelerated tests and exposure tests.

Tough marine climate

Moderate marine climate

Industrial climate

Countryside climate

For color coated steel with (aluminum) zinc plate as substrate, the coating thickness mainly affects the incision corrosion performance of color coated steel. The thinner the substrate, the thicker the zinc layer, and the better the incision corrosion resistance. It is currently recognized internationally that the zinc ratio ≥100g㎡ is the guarantee for effectively preventing incision corrosion of color coated steel plates. Taking a 0.5mm substrate as an example, the coating content per square meter on a single side is at least 50g.

Therefore, we recommend that customers pay special attention to the coating thickness when purchasing coated products, which will determine the service life of the coated steel plate. The right material can greatly reduce your use cost. Usually, no matter what material, we recommend that the zinc content per square meter should not be less than 120g, and the aluminum zinc content per square meter should not be less than 100g (that is, how many grams of the substrate is usually said).

3.Paint film

The paint surface of color-coated steel has an important impact on the appearance, performance, corrosion resistance, sun protection, and waterproof performance of color coated steel.

The quality of the paint surface of color-coated steel is directly related to the service life and performance of color-coated steel.

First of all, the paint surface of color-coated steel can improve the appearance of color-coated steel. By spraying paint, the surface of color-coated steel can present various colors and patterns to meet the needs and aesthetics of different users.

Secondly, the paint surface of color-coated steel can improve the performance of color-coated steel. By using special paint for color-coated steel, the adhesion of the paint can be effectively improved, and the paint film can be made more uniform, thereby enhancing the corrosion resistance, sun protection, and waterproof performance of color-coated steel. This special paint is not only suitable for metal surfaces, but also has excellent sun protection, corrosion resistance, and waterproof functions, which can extend the service life of color coated steel.

Paint film influence

Paint film anti-corrosion

However, the color coated steel paint surface also faces some challenges and problems. For example, the rust and dirt on the surface of the color-coated steel tiles need to be thoroughly removed before construction to ensure the adhesion of the paint. In addition, attention should be paid to environmental conditions during construction, such as maintaining good ventilation, avoiding construction under low temperature or high humidity conditions, and avoiding rain after spraying, etc., to ensure the quality and durability of the paint surface.

In summary, the color coated steel paint surface is not only about beauty, but also a key factor in the performance and life of color-coated steel. By choosing the right paint, the color-coated steel can be effectively protected and its service life can be extended, while meeting the needs of beauty and performance.

Use of color coated steel

The quality of color-coated steel is affected by many factors, including steel substrate properties, coating quality, mechanical damage, load and stress, etc. Long-term use and adverse environmental conditions may lead to coating failure, such as intergranular corrosion, fatigue cracks, etc., thus affecting the overall performance of color-coated steel. Therefore, taking appropriate preventive measures, such as increasing coating thickness, using weather-resistant and corrosion-resistant coatings, etc., is an effective means to prevent corrosion failure of color-coated steel plates.

Color coated steel Supplier

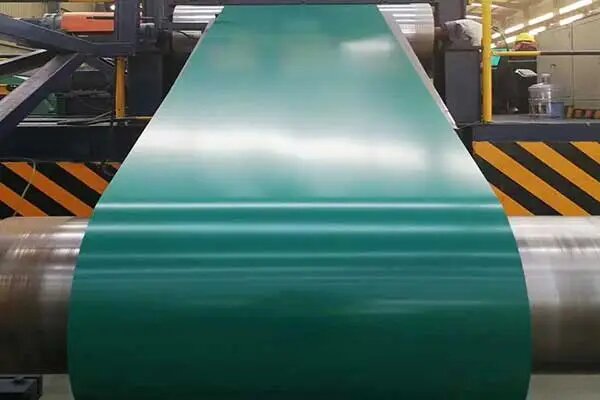

In Zhengzhou, China, Wanzhi Steel has an elite sales team. In Shandong, China, Wanzhi has its own factory. Our factory has 3 color coating lines with an annual production capacity of 320,000 tons. There are also two galvanizing lines with an annual production capacity of 350,000 tons. In addition, there are multiple sets of rolling equipment, shearing lines, etc. with different designs. We can meet all your needs for steel. For your inquiry information, we will contact you as soon as possible.

Looking forward to your inquiry, you can also come to our company and factory for a visit.