There are many ways to steel pipes classified. In addition to the common classification based on the production method, material, coating characteristics, cross-sectional shape and other characteristics of the steel pipe itself, they can also be classified according to connection methods and purposes when in use.

Connection Type Classification

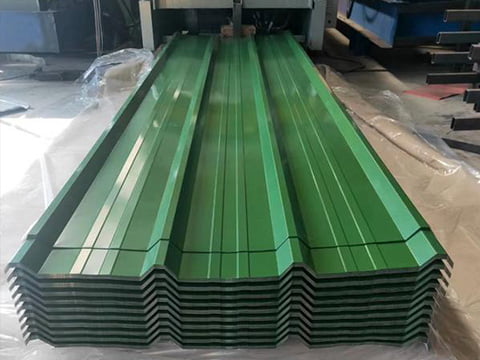

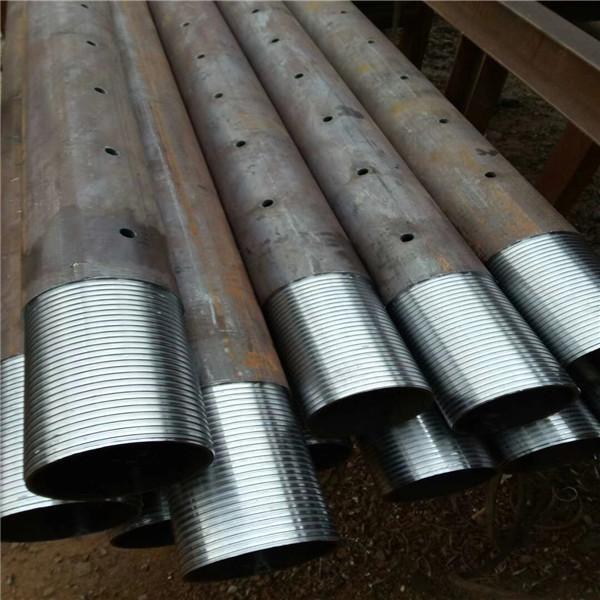

Steel pipes can be divided into: plain pipes (without threads at the pipe ends) and threaded pipes (with threads at the pipe ends) according to the pipe end connection method.

Threaded pipes can be divided into: ordinary threaded pipes and thickened threaded pipes at the pipe ends.

Thickened threaded pipes can also be divided into: external thickening (with external threads), internal thickening (with internal threads) and internal and external thickening (with internal and external threads).

Threaded pipe

Spiral steel pipe

Threaded pipes can also be divided into: ordinary cylindrical or conical threads and special threads according to the thread type.

In addition, according to user needs, threaded pipes are generally delivered with pipe joints.

Classification by purpose

- Steel pipes for pipelines. Such as: seamless pipes for water, gas pipes, steam pipes, oil pipelines, pipes for oil and gas trunk lines. Agricultural irrigation taps with pipes and sprinkler pipes, etc.

- Steel pipes for thermal equipment. Such as boiling water pipes and superheated steam pipes for general boilers, superheated pipes, large smoke pipes, small smoke pipes, arched brick pipes and high-temperature and high-pressure boiler pipes for locomotive boilers, etc.

- Steel pipes for the machinery industry. Such as aviation structural pipes (round pipes, oval pipes, flat oval pipes), automobile half-axle pipes, axle pipes, automobile tractor structural pipes, tractor oil cooler pipes, square and rectangular pipes for agricultural machinery, transformer pipes and bearing pipes, etc.

- Steel pipes for geological drilling. Such as: oil drilling pipes, oil drill pipes (square drill pipes and hexagonal drill pipes), drill braces, oil pipes, oil casings and various pipe joints, geological drilling pipes (core pipes, casings, active drill pipes, drill braces, clamps and pin joints, etc.).

- Steel pipes for chemical industry. Such as: petroleum cracking pipes, pipes for heat exchangers and pipelines of chemical equipment, stainless acid-resistant pipes, high-pressure pipes for fertilizers, and pipes for transporting chemical media, etc.

- Steel pipes for other departments. Such as: pipes for containers (pipes for high-pressure gas cylinders and general container pipes), pipes for instruments and equipment, pipes for watch cases, pipes for injection needles and medical devices, etc.

Straight seam steel pipe

Stainless steel pipe

Introduction to some Chinese national standard steel models:

GB/T33966-2017 Wear-resistant seamless steel pipe for conveying mortar

GB/T34020.1-2017 Double-layer welded steel pipe Part 1: Pipes for refrigerator pipeline system

GB/T34020.2-2017 Double-layer welded steel pipe Part 2: Pipes for automobile pipeline system

GB/T34020.3-2017 Double-layer welded steel pipe Part 3: Pipes for air conditioning and refrigeration equipment pipeline system

GB/T34105-2017 Seamless steel pipe for marine engineering structure

GB/T34107-2017 Precision stainless steel seamless steel pipe for rail transit vehicle braking system

GB/T34109-2017 Seamless steel pipe for rotary drilling rig drill pipe

GB/T34567-2017 Cold-bent corrugated steel pipe

GB/T35185-2017 Composite reinforced pipeline steel pipe for petroleum and natural gas industry

GB/T5310-2017 Seamless steel pipe for high-pressure boilers

GB/T50398-2018 Seamless steel pipe engineering design standard

GB/T20409-2018 Internally threaded seamless steel pipe for high-pressure boilers

GB/T21832.1-2018 Austenitic-ferritic duplex stainless steel welded steel pipe Part 1: Tubes for heat exchangers

GB/T21832.2-2018 Austenitic-ferritic duplex stainless steel welded steel pipe Part 2: Tubes for fluid transportation

Importance of steel pipe classified to steel selection

When customers choose steel pipes, the classification of steel pipes is of great significance.

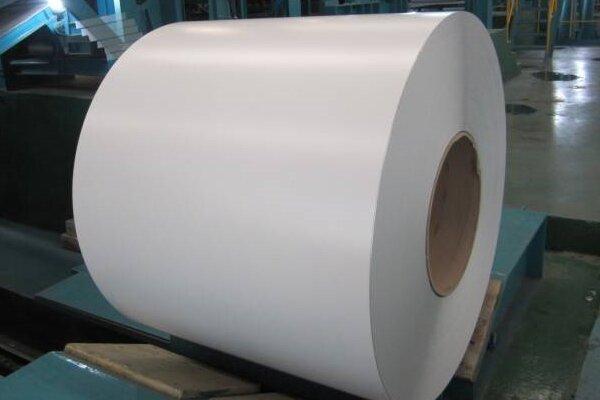

Steel pipes of different materials have different performance characteristics. For example, carbon steel pipes have higher strength and hardness, and are suitable for occasions with greater pressure and load; stainless steel pipes have good corrosion resistance and are suitable for use in corrosive environments. Customers can choose steel pipes of suitable materials according to the specific use environment and requirements to ensure the service life and safety of steel pipes.

Chemical Steel Pipe

liquid transport pipeline

Steel pipes can be classified into structural pipes, fluid transportation pipes, petrochemical pipes, etc. according to their use. Steel pipes for different purposes have different requirements in terms of size, precision, performance, etc. Customers can choose steel pipes of corresponding classification according to actual use, which can meet the needs of specific projects or projects and improve work efficiency and quality.

In short, understanding the classification of steel pipes is crucial for customers to choose appropriate steel pipes, which can improve project quality, ensure safety and achieve cost control.

Steel pipe supplier

Wanzhi provides various types of steel pipes and pipes of various national standards. If you are looking for a suitable supplier, Wanzhi Steel is a good choice. We have a professional service team and an excellent production factory. We welcome you to visit our factory. We look forward to your inquiry and we will contact you as soon as possible to provide you with detailed information.