GI Roofing Sheet

What Is GI Roofing Sheet?

The full name of GI roofing sheet is galvanized roofing board; That is a layer of zinc is plated on the steel plate to prevent corrosion, and the surface is galvanized, which can enhance its corrosion resistance and extend its service life to a certain extent.

The galvanized roof plate is composed of zinc layer and steel plate matrix, and the zinc layer can protect the steel plate matrix from corrosion. Due to its durability, rust resistance and affordability, GI roofing panels are commonly used for building roofs.

What Is Standard Size Of GI Roofing Sheet?

| Item | Product parameter |

| Product Name | GI Roofing Sheet |

| Product Thickness | 0.15 mm-0.8 mm |

| Zinc Coating Thickness | 40 g/m2-275 g/m2 |

| Overall Width | 750 mm ~ 1,250 mm |

| Effective Width | 600 mm ~ 1,050 mm |

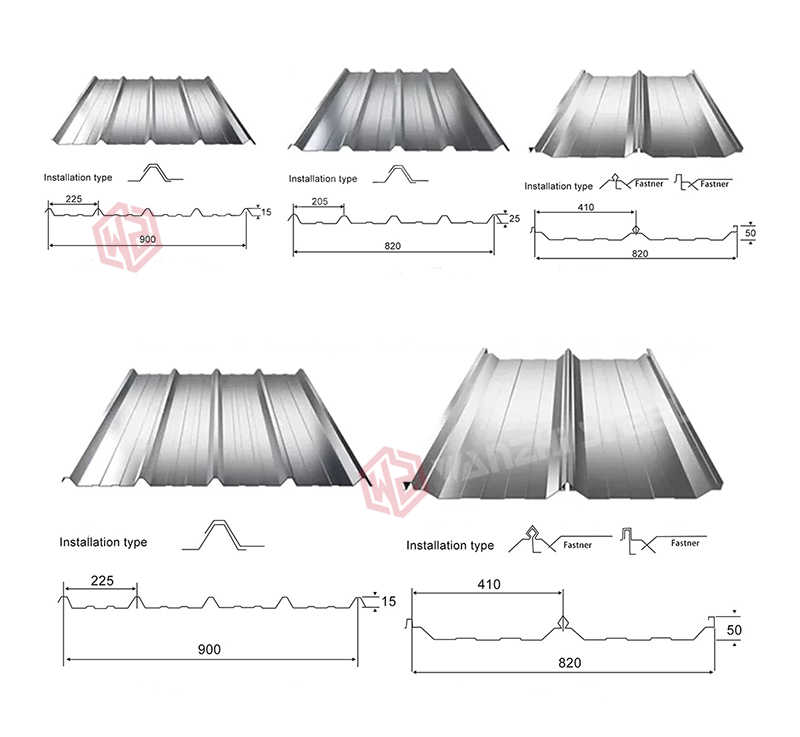

| Profiles | Wavy, Tiles, IBR, etc. |

| Spangles | Big spangles, regular spangles, small spangles, zero spangles |

| Length | As per your requirements |

| MOQ | 10 tons or 800 pieces |

| Production Capacity | 10000 Tons per Month |

| Package | Standard Export Package |

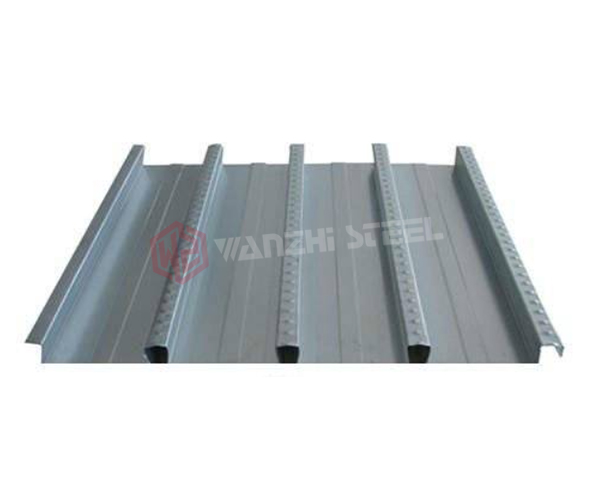

GI Roofing Sheet Production

Galvanized Roofing Sheet Advantages

- Strong anti-corrosion performance: because there is a galvanized layer on the surface of galvanized roof panel, it can effectively prevent corrosion.

- High durability: galvanized roof panels are not easily damaged by mechanical pressure, and are not vulnerable to damage caused by lightning.

- Long service life: galvanized roof panel has a long service life, up to 50 years.

- Economical and practical: compared with other roofing materials, the cost of galvanized roof panel is lower.

- Easy construction: the galvanized roof panel has the advantages of uniform specification, light weight, convenient processing, simple and fast construction, and can greatly improve the construction efficiency.

- High aesthetics: the surface of galvanized roof plate is smooth and smooth, and the color is beautiful, so that the laid roof is more beautiful and generous.

GI Roofing Sheet Advantages

Application Of GI Roofing Sheet

- all steel structure workshop frame

- single-sided color steel plate steel structure workshop

- Multi-span steel structure plant

- villa galvanized steel office

- cross color coated galvanized steel ceiling

- roof layer

- Large span plant, etc

Galvanized Roofing Sheet Rust Prevention

- Choose high-quality galvanized roofing sheet

High-quality galvanized roofing sheet can effectively avoid rust problems. It is recommended to choose regular channels to purchase galvanized roofing sheets with guaranteed quality, and try to avoid buying inferior products. - Surface treatment of galvanized roofing sheet

Before use, the surface of the galvanized roofing sheet needs to be treated to remove impurities such as oil and dust on the surface. You can use tools such as detergents and abrasives to make the surface smooth. After treatment, you can use paint or anti-corrosion paint and other materials for coating protection to extend the service life of the galvanized roofing sheet. - Regular maintenance of galvanized roofing sheet

Regular maintenance of galvanized roofing sheet can effectively avoid rust problems. It is recommended to maintain the galvanized roof sheet once every six months or every year, including cleaning surface impurities, checking the coating condition, and repairing the coating. At the same time, be careful not to scratch or damage the coating on the surface to avoid rust. - Precautions for storage of galvanized roofing sheet

Galvanized roofing sheet needs to be moisture-proof, sun-proof and ventilated during storage. Try to avoid storing in humid or direct sunlight, and keep ventilation to avoid long-term closed storage.

GI Roofing Sheet Production Storage

To sum up, galvanized roof panel is a very important building material in building engineering, which has the advantages of anti-corrosion, durability and convenient construction, and has been widely used in building roofing, wall and other fields.