Seamed steel pipe and Seamless steel pipe are two major categories of steel pipes. Steel pipes have promoted the vigorous development of industries such as industry and construction in our society. Steel pipes are divided into many categories, and seamless steel pipes and seamed steel pipes are one of them.What are the differences between them and what are their characteristics?

What are seamless steel pipes and seamed steel pipes?

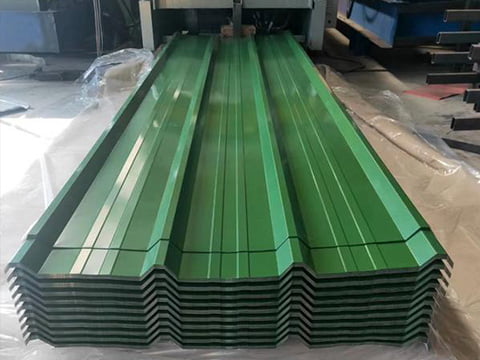

Seamed steel pipe

Seamed steel pipes are also called welded steel pipes. They are steel pipes with seams on the surface that are made by bending steel strips or steel plates into round, square and other shapes and then welding them.

Seamless steel pipe

Seamed steel pipe

They are made of carbon steel that is easy to weld. They are generally nominal in nominal size. The commonly used nominal sizes are DN15 to DN100, and DN150 is the largest nominal diameter.

The seamed steel pipes are often used to transport low-pressure fluids such as gas, cold water, and hot water, so they are also called gas pipes, water pipes, etc.

Seamless steel pipe

Seamless steel pipe is a kind of steel with a hollow cross-section and no seams around the circular, square, rectangular and other shapes. It is made by perforating the whole round steel, and there is generally no weld on the surface.

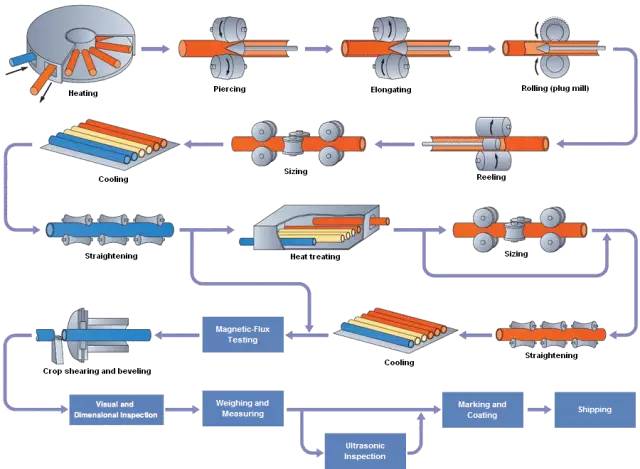

Hot rolled seamless steel pipe production process

The seamless steel pipe is widely used as a pipeline for conveying fluids. Compared with solid steel such as round steel, steel pipe has a lighter weight when the bending and torsional strength are the same. It is an economical steel and is widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipes, automobile transmission shafts, bicycle frames, and steel scaffolding used in construction, which can reduce costs.

Seamless steel pipe production process: hot rolling, hot expansion, cold drawing, cold rolling, and centrifugal casting.

The difference between seamless steel pipe and seamed steel pipe

1、Different processing techniques. Seamed steel pipes and seamless steel pipes are divided according to the processing form. Seamless steel pipes are made of high-quality carbon steel or alloy steel. The processing techniques of seamless steel pipes include cold drawing and hot rolling, while seamed steel pipes need to be rolled first and then welded.

2、Different appearance: There are usually weld ribs on the inner wall of the welded joint of the seamed steel pipe, while there are no weld ribs on the inner wall of the seamless steel pipe.

Straight seam steel pipe

Large Diameter Steel Pipe

3、The uses are different. Seamless steel pipes are mainly used as pipes or structural components for conveying fluids, and are mainly used in the machinery industry. Seamed steel pipes are mainly used for fluid and gas transportation in the construction industry, such as water, gas, compressed air and other low-pressure fluids. Pressure pipelines generally use seamless steel pipes.

4、Normally, the operating pressure that a seam steel pipe can withstand is below 20 kg, which is the safe range of use. It is generally used for low-pressure fluids such as water, gas, and compressed air.

Seamless pipes can withstand ultra-high pressure, and of course their wall thickness will increase accordingly. This needs to be designed according to the required pressure. They are often used in high-temperature and high-pressure equipment such as high-pressure oil pipes and boiler pipes. There are also seamless pipes for structures, which depends on the design requirements.

Seamless steel pipes are generally used for medium pressures equal to or greater than 1.6MPa. Seam steel pipes are formed by high-frequency welding of steel plates and are suitable for medium pressures less than 1.6MPa.

Summarize

At present, there are several kinds of seamless steel pipes that have been treated to be seamless, and the welds have been annealed. The pressure range is basically the same as that of seamless steel pipes. You can consider using them. There are also some seamless steel pipes on the market that are drawn or rolled with core heads after overall heating. The specifications are smaller. Such steel pipes are only seamless steel pipes in appearance, and their essence is not very ideal.

The above is the knowledge sharing about the difference between seamless steel pipes and seamless steel pipes. If you want to know more about Wanzhi Steel products, please send Inquiry to our sales service staff!

Things to note when purchasing

People often get confused when it comes to accurately describing the size of steel pipes and how to effectively communicate to the seller the size they want. Any misunderstanding or purchasing the incorrect size can lead to serious trouble.

Round steel pipe

Square steel pipe

So, what is the correct way to express steel pipe sizes?

There are 3 elements to steel pipe sizes that we need to know. A complete description of steel pipe size includes the outside diameter (OD), wall thickness (WT), and the length of the pipe (such as 20 feet 6 meters or 40 feet 12 meters). With these elements, we can calculate the weight of the pipe, the pressure that the pipe can withstand, and the cost per foot or meter. That’s why we always need to know the correct pipe size.

Suppliers of Seamless and Seamed Steel Pipe

Welcome to Wanzhi Steel for enquiries. We are an integrated industry and trade company that provides professional customization services and can produce products that meet your various customization requirements. Whether it is a seamed steel pipe or a seamless steel pipe, we are your best choice.