PPGi Steel Sheet

What is PPGI Steel Sheet ?

PPGI steel sheet is the full name of color-coated galvanized steel sheet, generally called color-coated steel. On the continuous unit, cold-rolled steel strip and galvanized steel strip (electro-galvanized and hot-dip galvanized) are used as substrates. After surface pretreatment (degreasing and chemical treatment), one or more layers of liquid coating are applied by roller coating. After baking and cooling, the resulting plate is a coated steel plate, which can also be called galvanized coated steel. Since the coating can have a variety of different colors, the coated steel plate is customarily called a color-coated steel plate. And since the coating is applied before the steel plate is formed, it is called a pre-coated steel plate internationally.

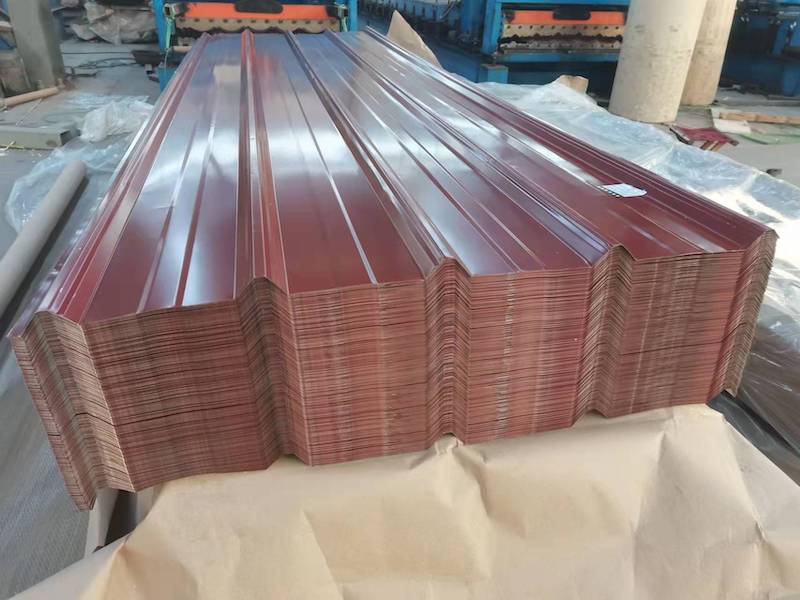

Red PPGI Sheet

PPGI Steel Sheet Process Flow

PPGI steel sheet is a product made of cold-rolled steel sheet and galvanized steel sheet as the substrate, which is subjected to surface pretreatment (degreasing, cleaning, chemical conversion treatment), coated with paint in a continuous method (roller coating method), and then baked and cooled.

Printing PPGI Steel

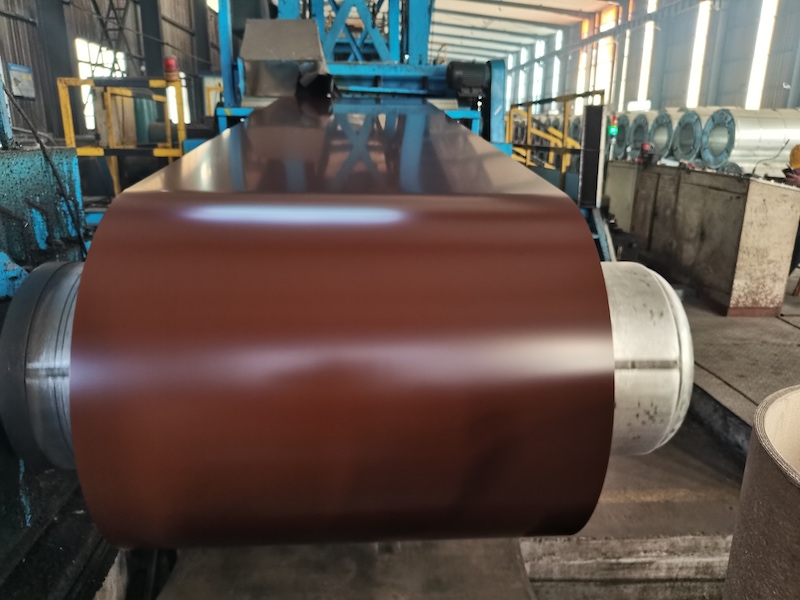

RAL Color Steel

PPGI steel sheet is usually cut from PPGI coil according to the required length.The main production processes of the common two-coating and two-baking continuous color coating unit process flow are: uncoiling → pretreatment → coating → baking → post-treatment → coiling.

PPGI Steel Sheet Specifications

| Item | Product Parameter |

| Product name | PPGI steel sheet, color-coated galvanized steel, color-coated steel sheet |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Zinc coating | 20-275g/m², or customized as required |

| Thickness | 0.12-2.00mm (±0.001mm); or customized as needed |

| Width | 600-1500mm (±0.06mm); or customized as needed |

| Coating structure | PE, SMP, HDP, PVDF, PU |

| Substrate type | hot-dip galvanized steel, electro-galvanized steel |

| Steel grade | DC51D+Z, DC52D+Z, DC53D+Z, S280GD+Z, S350GD+Z, S550GD+Z, DC51D+AZ, DC52D +AZ, S250GD+AZ, S300GD+AZ, S350GD+AZ, S550GD+AZ, SECC, SECE, BLCE+Z, BLDE+Z, BUSDE+Z ,etc. |

| Certificates | ISO 9001, SGS |

| Surface Colors | RAL series, wood grain, stone grain, frosted grain, camouflage grain, marble grain, pattern, nano, etc. |

| Monthly output | 5000-10000 tons |

| Futures | 15-35 days |

| Origin | China |

| Brand | WANZHI |

| Package | waterproof paper as inner packing, galvanized steel sheet or coated steel sheet as outer packing, side guard plate, then wrapped with steel belt. Or as per customer requirements |

PPGI Steel Sheet Features and Applications

PPGI steel sheet is lightweight, beautiful, has good corrosion resistance, and can be directly processed. It provides a new type of raw material for the construction industry, shipbuilding industry, vehicle manufacturing industry, furniture industry, electrical industry, etc., and has achieved good results such as replacing wood with steel, efficient construction, energy saving, and pollution prevention.

PPGI Corrugated Board

PPGI Sheet Application

PPGI steel sheet using galvanized steel sheet as the substrate, in addition to zinc protection, the organic coating on the zinc layer plays a covering and isolating role, which can prevent the steel sheet from rusting, and has a longer service life than galvanized steel sheet. According to experiments, the service life of the coated steel sheet is 50% longer than that of the galvanized steel sheet.

How to Extend the Service Life of PPGI Steel Sheet?

The service life of color coated sheets with the same galvanizing amount, the same coating and the same coating thickness will be very different in different regions and different use parts. For example, in industrial areas or coastal areas, the corrosion rate is accelerated and the service life is affected due to the effect of sulfur dioxide gas or salt in the air. In the rainy season, the coating will be corroded quickly and the service life will be reduced if it is soaked by rain for a long time or in areas where the temperature difference between day and night is too large and condensation is easy.

Factory production line

RAL 9003 PPGI

Buildings or factories made of PPGI steel sheets have a longer service life when they are often washed by rain. Otherwise, they will be affected by sulfur dioxide gas, salt and dust. Therefore, when designing, the greater the slope of the roof, the less likely it is to accumulate dust and other dirt, and the longer the service life; for those areas or parts that are not often washed by rain, they should be washed with water regularly.

Effect of paint film thickness on corrosion protection

From a microscopic perspective, there are many pinholes in the coating, and the size of the pinholes is enough to allow external corrosive media (water, oxygen, chloride ions, etc.) to penetrate into the substrate, and produce filamentary corrosion under a certain relative humidity.

The thicker the coating, the fewer pinholes, and the better the corrosion resistance of the substrate. When the normal coating thickness is above 20μm, its anti-corrosion effect is relatively stable.

Customer’s Positive Feedback

PPGI steel sheet Suppliers

There are many suppliers to choose from in the market, and you need to pay attention to a lot when choosing a supplier, whether it is experienced, whether it can supply quickly, etc.

Wanzhi Company is a good choice. We not only have an elite sales team, but also have our own factory in Shandong, China. Our factory has 3 color coating lines with an annual production capacity of 320,000 tons.

We welcome your inquiries and consultations, and you can also come to visit us. We are your trusted supplier partner.