Corrugated steel plate is a common metal material used in construction, packaging and manufacturing. It is processed by corrugated forming machines to form a wavy surface. Corrugated steel sheets are generally used for building materials such as roofs, walls and isolation, and can also be used for manufacturing materials such as packaging boxes and shelves.

Classification of corrugated steel plate

According to different uses and manufacturing processes, corrugated steel sheets can be divided into the following categories:

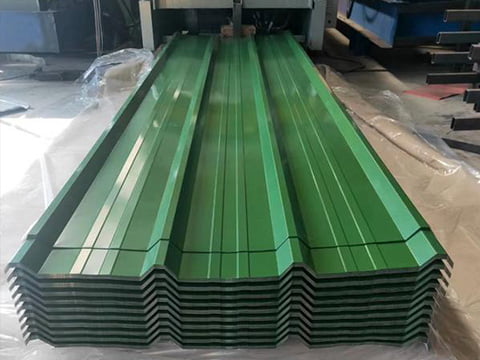

This type of corrugated steel sheet is coated with a color coating on the surface, which can not only provide good corrosion resistance, but also achieve a decorative effect. Color-coated corrugated steel sheets are usually used in building roofs and walls, manufacturing shelves and other fields.

Roofing plate production

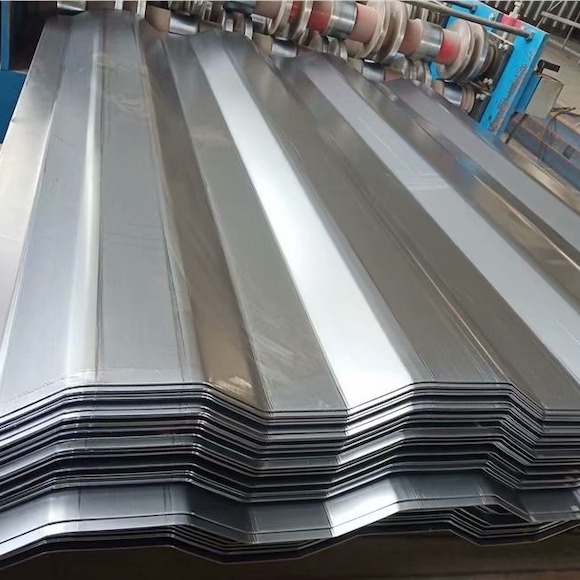

GI corrugated steel plate

This type of corrugated steel sheet is galvanized, which can provide better corrosion resistance and is suitable for use in humid environments and highly corrosive places such as acids, alkalis and salts. Galvanized corrugated steel sheets are generally used in building roofs and walls, road guardrails, trenches and other places.

This type of corrugated steel sheet is an alloy of aluminum, zinc and other metals, and has good high temperature resistance, corrosion resistance and mechanical properties. Alu-zinc alloy corrugated steel sheets are generally used for building materials and industrial equipment protection in special environments.

Stainless steel corrugated steel plate

This type of corrugated steel sheet is made of stainless steel and has good corrosion resistance and decorative properties. It is suitable for chemical equipment, medical equipment, food processing equipment and other fields.

The above types of corrugated steel sheets are classified according to different materials and processing processes, and each has specific characteristics and uses. In practical applications, the selection of appropriate corrugated steel sheet materials and specifications can be determined according to specific needs and environmental conditions. Whether it is construction, packaging or manufacturing industries, corrugated steel sheets have a wide range of application value, so factors such as material, specification and quality need to be considered when choosing.

Uses of corrugated steel plate

The corrugated structure of corrugated steel sheets gives them high strength and rigidity, so they are widely used in the fields of construction, packaging, and transportation.

Construction

First, in the field of construction, corrugated steel sheets are often used as covering materials for roofs and walls. Its excellent waterproof, anti-corrosion and wind-resistant properties enable it to effectively protect the building structure and extend the service life of the building. Corrugated steel sheets can also increase the wind resistance of the building, reduce the vibration of the walls and roofs, and improve the overall stability of the building. In addition, corrugated steel sheets can also be used to make partition walls, roof drainage systems, ventilation ducts, etc. inside the building.

Packaging field

Secondly, in the field of packaging, corrugated steel sheets are usually used to make various packaging boxes. Due to its certain compressive and seismic resistance, as well as good moisture-proof, acid-proof and alkali-proof properties, corrugated steel sheet packaging boxes can effectively protect goods from the influence of the external environment and reduce the damage rate of goods during transportation. At the same time, corrugated steel sheet packaging boxes can also be recycled, which meets environmental protection requirements.

Transportation

Thirdly, in the field of transportation, corrugated steel sheets are often used to make truck bodies and containers. Its corrugated structure can effectively increase the strength and stability of the box and improve the transportation safety of goods. At the same time, the corrugated steel box also has a light weight and good sealing performance, which can reduce the overall weight of the truck, reduce fuel consumption, and reduce transportation costs.

Container house

Container side plate

Other

In addition, corrugated steel can also be used to make various furniture, storage racks, display cabinets, etc. Its beautiful appearance, durability, and easy cleaning make it widely used in homes and commercial places.

In general, corrugated steel has good strength, stability and durability, as well as good anti-corrosion, waterproof, shockproof and other properties, so it has a wide range of uses in construction, packaging, transportation and furniture. With the development of science and technology and the improvement of technology, the application scope of corrugated steel will continue to expand and become a material with broad market prospects.

Calculation of corrugated steel plate price

Material:

The material of corrugated steel sheet has a great influence on the price. Generally speaking, there are different materials to choose from, such as ordinary carbon steel sheet, stainless steel sheet, galvanized steel sheet, etc. The price difference of different materials is large. Ordinary carbon steel sheet is relatively cheap, while stainless steel sheet is more expensive, but its corrosion resistance is stronger.

Thickness:

The thickness of corrugated steel sheet is also an important factor affecting the price. Generally speaking, the greater the thickness, the stronger the bearing capacity of the steel sheet, but the higher the price. Because the production of thicker steel sheets requires more raw materials and production costs.

Size:

The size of the corrugated steel sheet will also affect the price. Generally speaking, the larger the size, the higher the price.

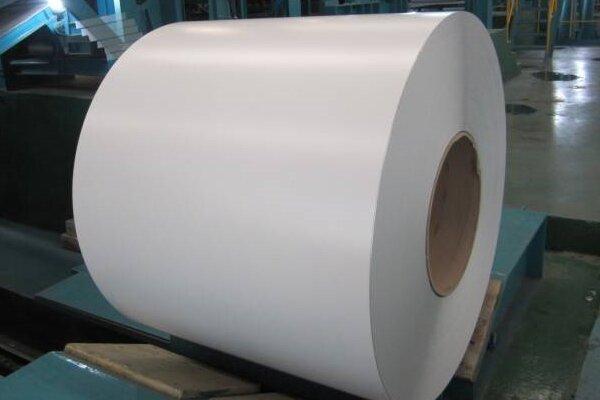

Surface treatment:

The surface treatment method of corrugated steel sheet is also an important factor in price calculation. Surface treatment methods such as galvanized corrugated steel sheet and color-coated corrugated steel sheet will increase the anti-corrosion and aesthetic performance of the steel sheet, but will make the price different.

Quantity:

The purchase quantity is also one of the factors affecting the price. Generally speaking, the more the quantity, the lower the price per ton.

Service:

Choosing a manufacturer can ensure product quality and after-sales service. High-quality corrugated steel sheets have a smooth surface, are free of bubbles and impurities, and have good compression, tension and impact resistance.

In summary, the price calculation of corrugated steel sheets takes into account factors such as material, thickness, size, surface treatment, quantity and service. According to actual needs, you can choose suitable corrugated steel sheets based on these factors and conduct detailed price negotiations with suppliers. At the same time, you can also make a budget based on different combinations of the above factors to get a more reasonable price.

Selection of corrugated steel plate

In short, when purchasing corrugated steel plates, you should choose the right material according to the purpose and environmental characteristics of the building.

Container house

Galvanized roofing plate

Secondly, choose the right thickness according to the structure and load requirements of the building. The thicker the thickness, the greater the gravity density and the higher the strength, but the weight will also be greater, and the load requirements for the building will also be higher. Therefore, when choosing the thickness of the roof board, you need to choose it according to the structure and load requirements of the building. And, choose roof boards produced by regular manufacturers. Choosing roof boards produced by regular manufacturers has guaranteed quality and complete after-sales service, which can avoid problems in later use.

Corrugated Steel Plate Supplier

There are many suppliers available in the market, and choosing the right corrugated board supplier is challenging. An experienced supplier is a good choice. As a company with more than ten years of development, Wanzhi Steel has always been praised by customers for its best service and excellent quality. We have our own sales team and production factory, you can come to visit and communicate. Welcome your inquiries.