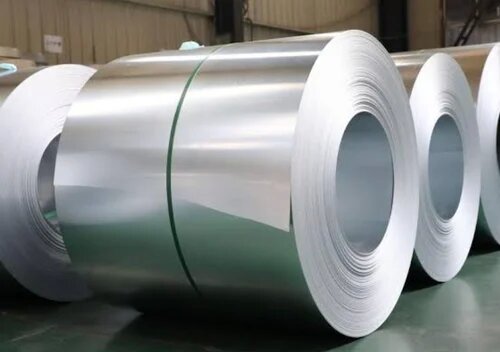

Galvalume Steel coil

Why More Choices Galvalume Steel

Galvalume steel coil has a Gorgeous silver finish.

Lasting

Galvalume steel has excellent corrosion and wear resistance. Its corrosion rate is about 1 micron per year. Depending on the environment, it can be used for an average of 70 to 100 years, which shows that it is permanent with the life of the building.

Easy to maintain and manage

Galvalume steel not only has a long life, but also has low maintenance costs. Zinc sheet has no surface coating, the coating peels off over time and does not need to be repaired. In fact, both aluminum and zinc can continuously form passivation protective layers in-situ in air with self-healing functions for surface defects and scratches.

Galvalume Steel Coil Making Process

Galvalume Steel Coil Specification

| Items | Parameters |

| STANDARD | JIS G3321, ASTM A792M / A924M or equivalent |

| COATING MASS | AZ30 ~ AZ150 |

| SURFACE FINISH | Small Spangle, Regular Spangle and Big Spangle (Various colors available Green, Blue, Red and Gold) |

| SURFACE TREATMENT | Chromated / Unchromated Treatment, Oiled or Resin Coated (Anti Finger Print), Dry |

| EDGE CONDITION | Treatment, Oiled or Resin Coated (Anti Finger Print and Non Anti Finger Print) |

| Coil Weight | 3-8 tons or as per your requirements |

| Package | Standard Export Package |

Galvalume Steel Coil Uses

Because of the excellent properties of aluminum-zinc steel coil, it has been widely used in many fields. The following are some common applications of aluminum-plated zinc steel coils:

1、roof

Because of its light weight, durability, ease of handling and installation, aluminum coated zinc steel coils are often used on the roofs of residential, commercial and industrial buildings. They have excellent corrosion resistance and provide long-term protection from environmental factors such as rain and snow. coil can be molded into a variety of profiles, such as standseam profiles, corrugated profiles, and tile profiles, allowing for greater design and installation versatility.

2、Cladding and siding

Aluminum-zinc coated steel coils are also widely used in cladding and siding of buildings. They have a stylish and durable exterior surface while protecting the underlying structure from moisture, wind and other natural environmental factors. coil is available in a variety of colors and finishes, enabling a wide range of design possibilities.

Aluminum-plated zinc coils protect against fading, chalking and cracking, resulting in a durable, low-maintenance coating option.

3、Automobile industry

In the automotive industry, aluminum-zinc coated steel coils can be used to manufacture various auto parts. Coils are used to make body panels such as hoods, fenders, doors and roofs. Aluminized zinc steel has a high strength-to-weight ratio that helps improve fuel efficiency and vehicle performance. In addition, coil’s corrosion resistance prevents rust and extends the service life of automotive components.

4、Electric appliance

In the automotive industry, aluminum-zinc coated steel coils can be used to manufacture various auto parts. Coils are used to make body panels such as hoods, fenders, doors and roofs. Aluminized zinc steel has a high strength-to-weight ratio that helps improve fuel efficiency and vehicle performance. In addition, coil’s corrosion resistance prevents rust and extends the service life of automotive components.

5、Structure

Aluminum-zinc coated steel coil is widely used in various structures in the construction industry. They are used to produce beams, columns, purlins, trusses and other components. coil’s high strength and long life enable it to withstand huge loads and structural stresses. Their corrosion resistance enables lasting performance even in harsh environments. Aluminized zinc steel coils are commonly used in residential and commercial construction projects.

6、Industrial application

Aluminum-zinc coated steel coils are used in a variety of industrial applications. Used in the manufacture of storage tank equipment, piping systems, industrial roofs and industrial equipment. coil’s corrosion resistance and durability make it ideal for use in harsh industrial locations such as chemical processing plants, manufacturing facilities, and warehouses.

7、Solar panel

The aluminum-zinc coated steel coils are used in the solar energy field to manufacture mounting systems and frames for solar panels. coil’s high strength and corrosion resistance make it ideal for outdoor applications. They provide a strong and resilient platform for solar panels, ensuring long-term performance in harsh weather conditions.

These are some of the main uses of aluminum-zinc coated steel coils. Their combination of corrosion resistance, strength, formability and aesthetics makes them highly adaptable and suitable for a wide range of industries and applications.

Galvalume Steel Supplier

When choosing, be sure to be careful, a good manufacturer, can let you get the product you want at the right price; An excellent seller can allow you to reduce unnecessary problems in the transaction process, so that the product can reach your hands more smoothly.

Wanzhi steel as a production and sales as one of the company, we have a professional production team and excellent sales team, fully in line with your best choice. Please choose Wanzhi, will not let you down.