GalvaNized Steel Coil

What is Galvanized Steel Coil?

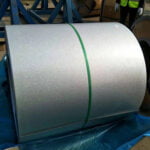

Galvanized steel coil is steel strip or coil where hot or cold rolled steel has been treated with zinc to prevent corrosion. Galvanizing involves giving the steel coil a zinc coating by dipping it into a molten zinc bath or through a continuous hot dip galvanizing process.

The zinc coating acts as a barrier between the steel and the surrounding environment, preventing rust and corrosion on the steel surface. It acts as a sacrificial layer, meaning that if the coating is broken or scratched, the zinc will corrode before the steel underneath.

Galvanized steel is typically made from mild steel, which has a carbon content of less than 0.2%. This steel is chosen because it is easy to work with and has excellent welding and forming qualities.

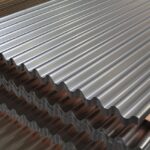

GI can be formed or coated with various coatings, becoming a new hot-selling product. Such as: galvanized corrugated sheet, color-coated galvanized coil (PPGI), etc.

Galvanized Steel Coil Specifications

| Item | Product Parameter |

| Name | Galvanized Steel Coil |

| Thickness | 0.14-1.2 mm |

| Width | 600 ~ 1500 mm , according to customer’s special request |

| Lenght | As per your requirements |

| Zinc Coating | 30 g/m² – 275 g/m² |

| Tolerance | Thickness: ±0.03mm Length:±2mm Width: ±2mm |

| Material grade | DX51D+Z、DX52D+Z、DX53D+Z、DX54D+Z、DC51D+Z、DC52D+Z;SGCC; S350GD etc. |

| Spangle | Zero spangles, small spangles, regular (big) spangles |

| Surface treatment | Chromated unoiled, galvanized |

| Standard | ASTM, JIS, EN, BS, DIN |

| Certificate | ISO 9001/ISO 14001/SGS/SONCAP |

| Technical | Hot dip galvanizing, Electro galvanizing |

| Coil Weight | 2-15Tons ton per coil |

| Our Advantage | 1. Reasonable price with excellent quality 2. Abundant stock and prompt delivery 3. Rich supply and export experience, sincere service |

| Package | Standard Export Package |

| HS Code | 72104900 |

| Delivery cycle | 5-20 working days after payment. Depending on order quantity |

Galvanized steel surface spangle

In previous steelmaking processes, the surface of galvanized steel coils often contained large, flower-like patterns of zinc crystals called “flakes.” Flakes resembled large, hexagonal snowflakes. While today’s galvanized steel still contains flakes, modern steel mills produce galvanized steel with flakes that are almost unnoticeable to the naked eye. This is known as minimal flake and zero flake galvanized steel.

Big

Regular

Small

No

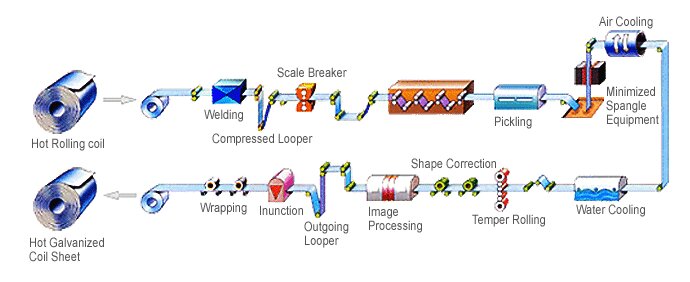

Galvanized Steel Coil Production

There are two widely used methods for applying zinc to steel coils:

Hot dip galvanizing

Hot dip galvanizing (HDG) technology involves immersing the steel strip in a bath of molten zinc to form a protective coating. Hot-dip galvanized steel coils can be produced by continuous galvanizing lines with non-oxidizing annealing furnaces (Sendzimir process and its variants) or using wet or dry fluxes (Cook-Norteman process and its variants). Continuous hot dip galvanizing lines with non-oxidizing annealing furnaces start with hot or cold rolled unannealed (hardened) steel coils. Hot dip galvanizing technology is quite common and is widely used in construction, machine building and other industries. Large steel mills and re-rolling/coating plants use this technology.

Electrolytic galvanizing

Electrolytic galvanizing (Electrogalvanization) is an electrochemical process in which a layer of zinc is applied in an acidic or alkaline electrolyte. The main idea of the technology is to use oxidation and reduction reactions during which electrons move through an electron transport chain while zinc ions in the electrolyte flow from the anode to the cathode. Such coatings are usually suitable for thin gauge materials; the coating thickness is usually 5-12 microns and can be precisely adapted to the product shape.

Compared with hot-dip galvanized coatings, electrolytic zinc coatings are more plastic due to the absence of an intermediate brittle layer. The main application areas of such products include automotive, transportation and machinery manufacturing, among others.

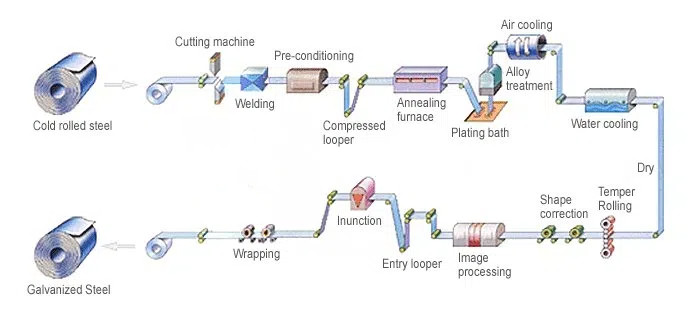

Galvanized Coil Production Flow Diagram

Hot Rolled Raw Material Production

Cold Rolled Raw Material Production

Applications of Galvanized Steel Coil

Construction industry: manufacturing low-rise building structures, light steel thin-walled structures, sandwich panels, thermal pipe linings and various insulation materials, air conditioning systems, metal roof tiles, profiled panels, culvert pipes, door cladding, elevators, PVC windows and plastic door reinforcement profiles, gypsum board European fasteners, etc.

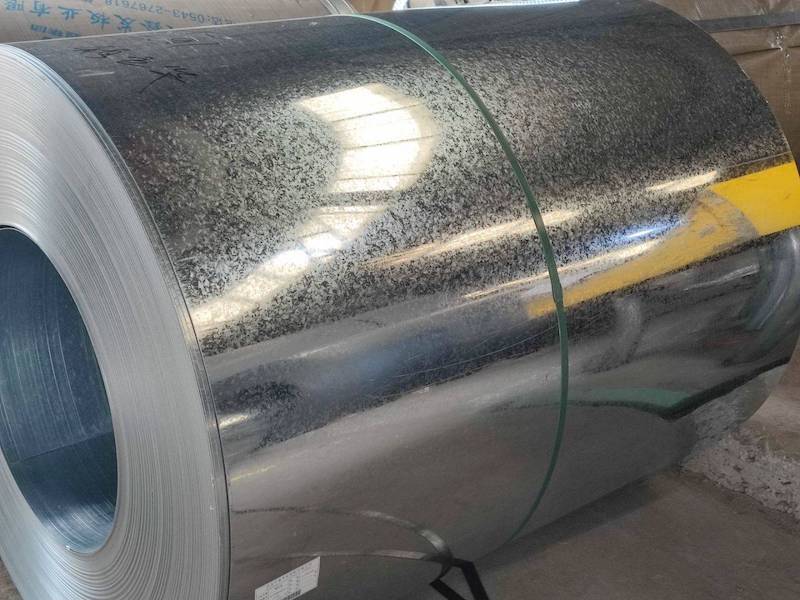

Spot galvanized steel coil

Your Attractive Heading

Automotive industry: manufacturing internal and external body parts of automobiles, repairing external body parts of public transportation vehicles (such as buses and trams).

Machinery manufacturing, instrumentation industry: manufacturing electromechanical equipment, household appliances, instrument and equipment housings, packaging, etc.

Household items: tableware, bowls, buckets, cans, bathtubs, etc.

Color-coated (and other types of coatings) rolled steel production

Galvanized Steel Coil Packaging

First with plastic package, then use waterproof paper, finally packed in iron sheet or according to customer’s special request.

Galvanized Steel Coil Factory Suppliers

Factory spot

Spot inventory

Wanzhi Steel is one of the leading suppliers of galvanized steel coils in China. We have a factory in Boxing County, Shandong Province. At the same time, we are an experienced trading company, serving customers from more than 100 countries, such as Turkey, Poland, Chile, Turkmenistan, Brazil, Ukraine, Philippines, etc. In addition, we have a wide range of steel products to choose from. For example, we also offer galvanized corrugated roofing panels, color-coated galvanized steel, and other finished products. We also provide other value-added services such as profile processing, shearing, cutting, etc. Please contact us for more information! You can follow us on YouTub or Facebook to learn about our news.