GalvaNized Steel Sheet

Galvanized Steel Sheet Introduce

Galvanized steel sheet is a steel sheet coated with a layer of zinc to prevent corrosion. The zinc layer acts as a sacrificial anode, protecting the steel below from rust and other forms of corrosion. This makes galvanized steel plates ideal for outdoor applications and environments where exposure to moisture and other corrosive substances is a concern.

A variety of galvanizing processes that can be selected in actual production, but the most common and commonly used method is hot dip galvanizing.

Galvanized Steel Sheet Metal Gauge Chart

| Item | Product Parameter |

| Substrate | GI steel |

| Thickness | 0.2-4 mm,Thickness tolerance ±0.002mm |

| Width | 600 ~ 1250 mm,Width tolerance ± 3mm |

| Lenght | Customized according to customers |

| surface | Common zinc flowers, large zinc flowers, small zinc flowers, no zinc flowers |

| Design | can choose the template , but also to customize |

| Processing technology | Cut, bend, weld, punch |

| Zinc layer | 30g/m²,40g/m²,80g/m²,100g/m²,275g/m² |

| Package | Standard Export Package |

Galvanized Steel Sheet Production

Common Galvanized Steel Sheet Style

In fact, Galvanized metals are used everywhere!

The bodies of cars 、household appliances and many bicycles are made from galvanized metals. Some drinking water pipes are still made from galvanized steel. Cool rolled sheet metal is also frequently galvanized. Nuts, bolts, tools, and wires of all kinds are now galvanized because it is a cheap process, and helps boost the metal’s lifespan!

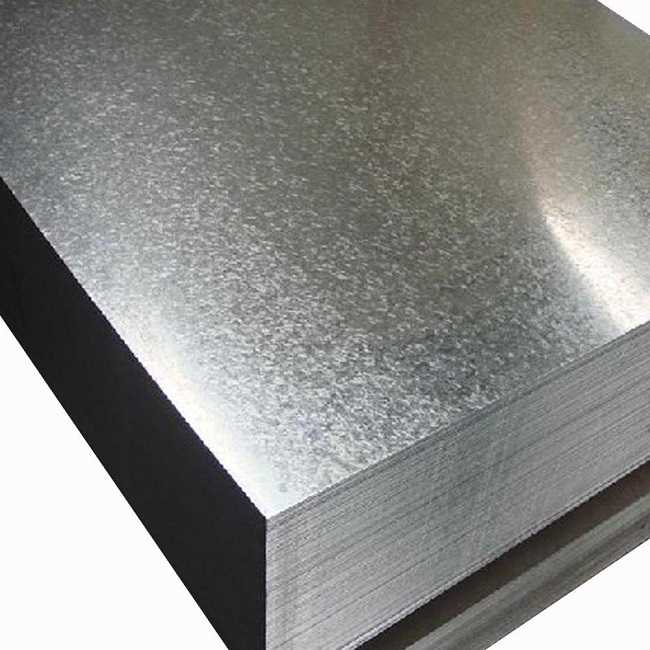

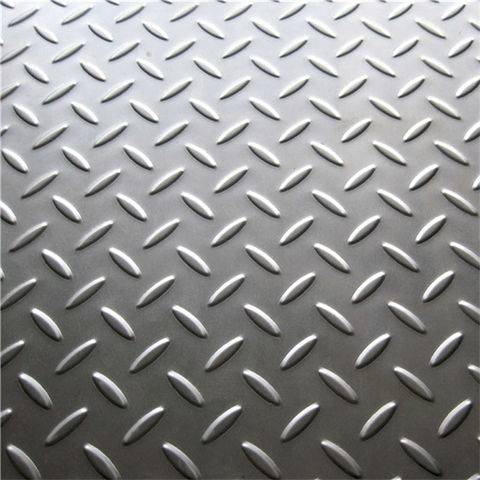

There are many ways to use galvanized steel sheets. The pictures below are some of our common galvanized steel plates.

GI Sheet

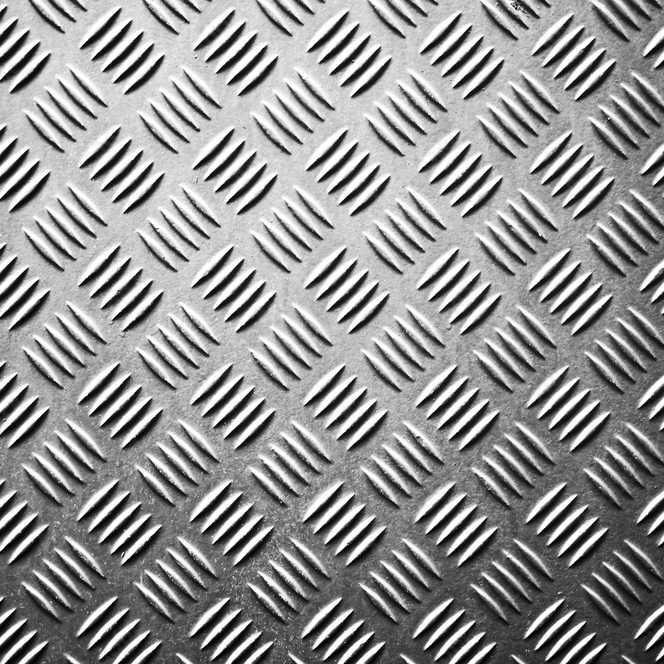

Anti-slip Sheet

Orange Peel

Corrugated Sheet

Punched Plate

Diamond Pattern

Advantages of Galvanized Steel sheet

1、Low initial cost:

The initial cost of galvanizing is lower than many other commonly used steel protective coatings. (The cost of applying labor-intensive coatings such as paint has risen much more than the cost of operating plants such as galvanizing.)

2、Less maintenance/longest use:

Even in cases where the initial cost of galvanizing is higher than an alternative coating, galvanizing is almost always cheapest in the long run (because it lasts longer and requires less maintenance). And, when buildings are located in remote areas and factories are closed or production is disrupted, maintenance can cause problems and increase costs.

3、Long life:

In most rural environments, the life expectancy of Zinc coatings on typical structural parts is well over 50 years. Even in heavily exposed urban and coastal areas, its life expectancy is more than 20 to 25 years.

4、The toughest coating

The Zinc coatings have a unique metallurgical structure that provides excellent resistance to mechanical damage in transportation, installation and service.

5、Automatically protect the damaged area:

Zinc coatings are preferred over steel corrosion to provide cathodic or sacrificial protection for small areas of steel exposed by damage. Unlike organic coatings, small damaged areas do not need to be repaired.

6、Comprehensive protection:

Every part of the galvanized product is protected, even grooves, sharp corners and inaccessible areas. Any coating applied to the structure or manufacture after completion will not provide the same protection as galvanizing.

7、Easy inspection:

Zinc coatings are easy to evaluate by the naked eye and can be measured using simple non-destructive thickness testing methods. The galvanizing process works like this: If the coatings look good and continuous, then they are good and continuous.

Galvanized Steel Sheet Near Us

The characteristics of galvanized steel make it suitable for use in a variety of projects and industries, including agriculture, solar energy, automobiles, construction, etc.

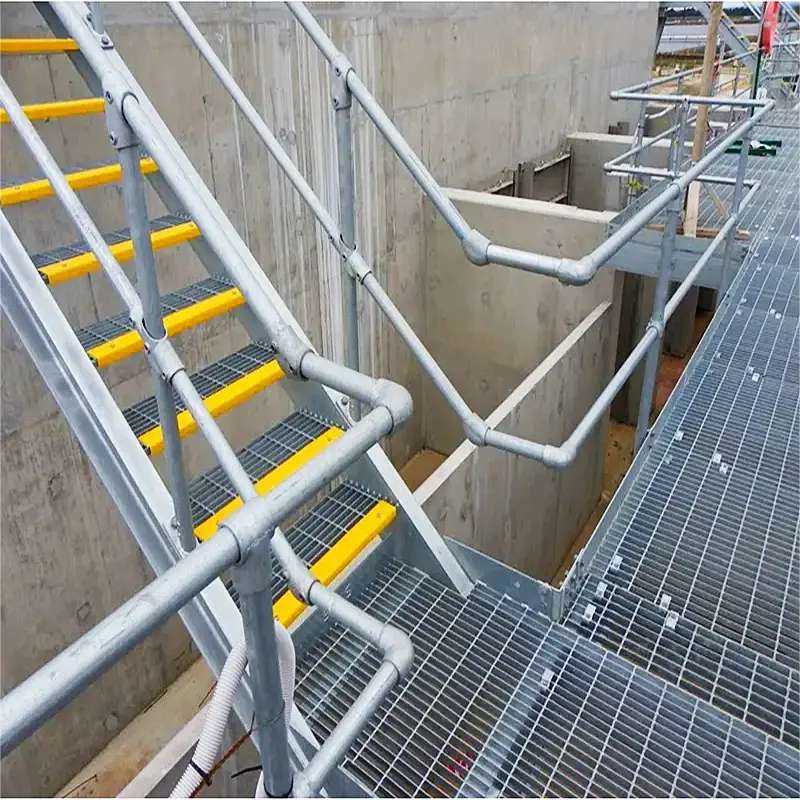

Around us, there are many projects that use galvanized steel, for example, the non-slip floor in the office elevator, the common stainless steel hole plate in the family tool room, the kitchen cabinets in the restaurant, the roof of the factory, and so on.

Steel cabinet

Steel truss

Elevator floor

Galvanized Steel Sheet Manufacturer

Wanzhi’s Galvanized Steel Sheet

Galvanized Steel Sheet Supplier

Wanzhi Company is a production and sales in one company, we produce a variety of steel products, including galvanized steel, aluminum plated zinc steel, color coated steel, corrugated steel, hot rolled and cold rolled steel and so on.

We have our own inspection laboratory with the aim of producing quality products that meet the standards for our customers. We support customers to customize steel products, and also support third-party testing, to ensure that we provide you with the best quality products.

Your free enquiry is welcome.