Galvalume Steel Sheet

What Is Galvalume Steel Sheet

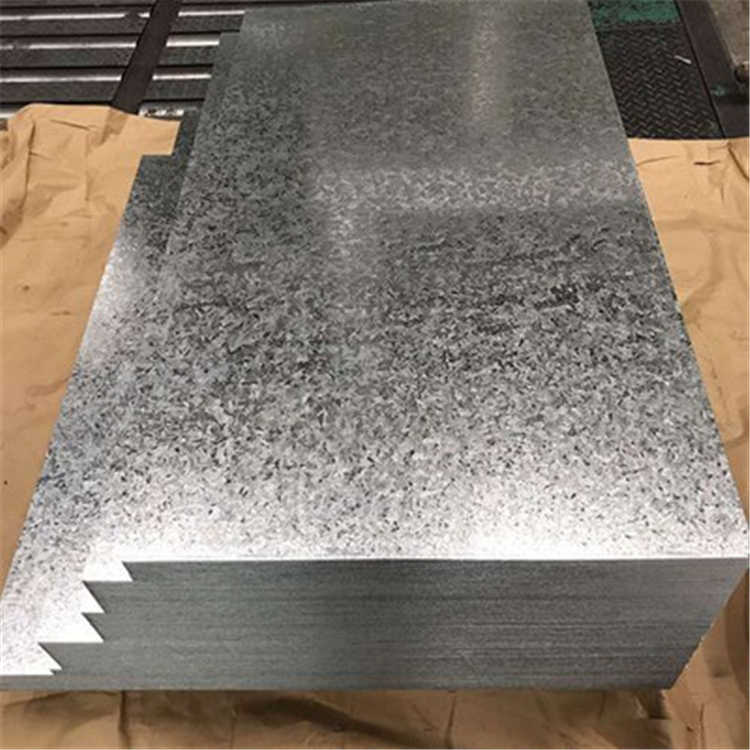

Galvalume steel sheet is the registered name of a new type of steel plate. It is made of cold-rolled or hot-rolled steel plate through hot dip plating. The coating composition is 55% aluminum, 43.4% zinc and 1.6% silicon. Due to its excellent corrosion resistance, this steel plate is gradually replacing galvanized steel plate and is widely used around the world.

The surface of the galvalume Steel Sheet is characterized by smooth, flat and gorgeous zinc flowers, and the primary color is silver-white. Its production process is similar to the process of aluminum plating of galvanized steel plate, which is a continuous melting coating process.

Galvalume Steel Sheets Near Us

Galvalume steel plate has many applications in our lives; finds extensive applications in various sectors, including construction, automotive manufacturing, home appliances, industrial equipment, and solar photovoltaic systems.

1.The construction industry commonly utilizes aluminized zinc steel plate for roofing, wall cladding, garage doors, rain pipes; and other building components due to its exceptional corrosion resistance and durability.

Aluminized zinc steel application

2.In the automotive sector, aluminum-plated zinc steel plates are employed for fabricating body structures, chassis components, fuel tanks, and other parts to safeguard vehicles against corrosion.

3.Home appliances such as refrigerators, washing machines,and ovens incorporate aluminized zinc steel plates in their shells to enhance both aesthetics and corrosion resistance.

4.Industrial equipment like switchgear cabinets and control panels often rely on aluminum-plated zinc steel plates for long-term protection against environmental factors.

5.Solar photovoltaic bracket systems extensively utilize aluminum-plated zinc steel plates due to their ability to withstand outdoor conditions while providing reliable support.

Galvalume Steel Roofing

Galvalume Steel Sheet Price

When buying goods, we often pay attention to the price, but there is a Chinese proverb: Cheap goods It is difficult to have good quality goods, it does not mean that cheap prices can not buy good products, but cheap prices are more likely to be deceived and buy bad products. And when buying bulk steel, transportation conditions, packaging, supplier services all need us to consider.

Therefore, it is necessary to select the most suitable supplier based on a variety of situations and combined with their own circumstances.

Galvalume Steel Sheet Specification Parameter

The thickness of aluminum-plated zinc alloy layer is an important parameter of aluminum-plated zinc plate, usually in 10-15 microns. Thicker aluminum-plated zinc alloy layer proposed to improve the corrosion resistance, but the corresponding increase in cost

The thickness of the aluminized zinc substrate is generally 0.4-2.0 mm, and the appropriate steel plate thickness can be selected according to actual needs

The surface of aluminized zinc plate can be treated in a variety of ways, such as spraying, hot rolling, cold rolling, etc. Different surface treatment methods have certain effects on corrosion resistance and aesthetics

The size of aluminum plated zinc plate can be customized according to customer needs of different sizes of products, common specifications include 1000*2000mm、1200* 2400 mm and so on.

Factory Laboratory

Wanzhi has an advanced factory laboratory and fully equipped experimental equipment to ensure that customers receive high-quality and qualified products.

Experimental instrument