Hot Rolling And Cold Rolling Concepts

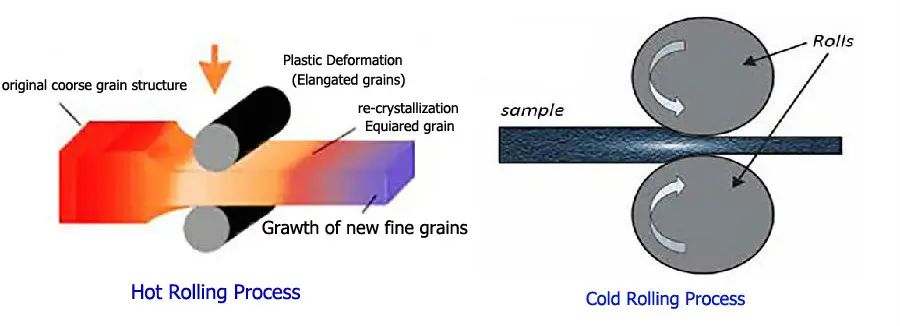

1.Hot Rolling

Hot Rolling is Continuous casting slabs or blooming slabs are used as raw materials, heated by a step-by-step reheating furnace, dephosphorized by high-pressure water, then entered into the roughing mill, and then into the finishing mill after cutting head and tail, and then precisely controlled by computer. After the final rolling, it is coiled by laminar cooling (the cooling rate is precisely controlled by the computer) and coiler to become a direct roll. The curling head and tail of straight hair are often tongue-shaped and fishtail-shaped, and the accuracy of thickness and width is relatively poor, and the crimping often has defects such as wave shape, hem folding, tower shape and so on.

Its coil weight is heavier and the inner diameter of the coil is 760mm (commonly used in the pipe industry). After the straight hair coil is treated with head-cutting, tail-cutting, edge-cutting and multi-pass straightening, leveling, and then cutting or rewinding, it becomes: hot-rolled steel plate, flat hot-rolled steel coil, longitudinally cut strip and other products. After pickling and oiling, the hot-rolled finishing coil is formed into hot-rolled pickling coil.

2.Cold Rolling

Hot rolled steel coil is used as raw material, after pickling to remove the oxide skin, the finished product is rolled hard coil. Because of the cold hardening caused by continuous cold deformation, the strength and hardness of the rolled hard coil increase, the ductility and plasticity index decrease, and the stamping performance weakens. It can only be used for simple deformed parts.

Rolled hard coil can be used as raw material in hot dip galvanizing plant, because hot dip galvanizing units are equipped with annealing lines. The roll weight is generally 6~13.5 tons, and the inner diameter of the steel coil is 610mm. Generally, the cold continuous rolling plate and coil should be deannealed by continuous annealing (CAPL unit) or cover furnace to eliminate the cold hardening and rolling stress, and achieve the mechanical properties specified in the standard. The surface quality, appearance and dimensional accuracy of cold-rolled steel plate are superior to those of hot-rolled plate.

Hot Rolling & Cold Rolling Process

Advantages And Disadvantages Of Hot Rolling

Advantages

It can destroy the casting structure of the ingot, refine the grain of the steel, and eliminate the defects of the microstructure, so that the steel structure is more dense, and the mechanical properties can be improved. This improvement is mainly reflected in the rolling direction, so that the steel is no longer isotropic to a certain extent; Bubbles, cracks and looseness formed during pouring can also be welded under high temperature and pressure.

Cons

1.After hot rolling, the non-metallic inclusions (mainly sulfides and oxides, as well as silicates) inside the steel are pressed into sheets, and the phenomenon of lamination (sandwich) appears. Delamination greatly worsens the tensile properties of steel along the thickness direction, so it is possible to tear between layers when the weld is contracted. The local strain induced by weld contraction often reaches several times of the yield point strain, which is much larger than that caused by load.

2.Uneven cooling will cause residual stress. Residual stress is the internal self-equilibrium stress in the absence of external force. Hot-rolled steel of various sections has such residual stress. The larger the section size of general steel, the greater the residual stress. Although the residual stress is self-equilibrium, it still has a certain effect on the performance of steel members under external forces. Such as deformation, stability, anti-fatigue and other aspects may have adverse effects.

Advantages And Disadvantages Of Cold Rolling

Advantages

Cold rolling molding speed, high yield, and no damage to the coating, can be made into a variety of cross section forms to meet the needs of various conditions of use; Cold rolling can produce great plastic deformation of steel, thus increasing the yield point of steel.

Cons

1.Although there is no hot plastic compression in the molding process, there is still residual stress in the section, which will inevitably affect the overall and local buckling characteristics of the steel.

2.The cold-rolled steel style is generally an open section, which makes the free torsional stiffness of the section low. It is easy to appear torsion when bending, and easy to appear bending and torsional buckling when pressurized, and the torsional resistance is poor.

3.The wall thickness of cold-rolled steel is small, and it is not thickened at the corner of the connection of the plate parts, and the ability to withstand local concentrated load is weak.

Application Areas Of Hot Rolling And Cold Rolling

Hot rolling and cold rolling have their own advantages and application areas. Here are their uses in their respective application fields.

1. Application field of hot rolling.

Hot rolling is widely used in the manufacture of large steel and alloy materials, including machinery and equipment, ships, bridges, construction, automobiles and other fields. Hot-rolled steel plates and steel plates are widely used in building structures, container manufacturing, pressure vessels, oil pipelines and other mechanical equipment.

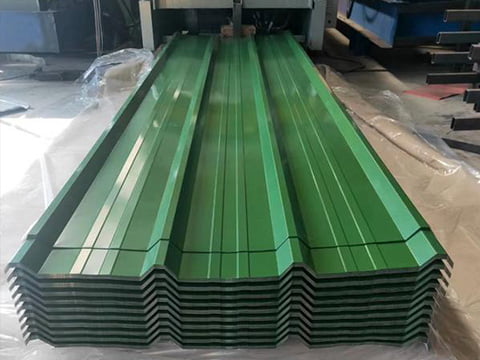

2. Application field of cold rolling.

Cold rolling is mainly used in the field of high-precision manufacturing, such as electronic parts, optical instruments, precision instruments and auto parts. Because of the good surface smoothness of cold-rolled materials, it can also be used for products with high appearance requirements, such as advanced color coated plates.

In a word, hot rolling and cold rolling are the two most commonly used methods in metal processing, and they have different characteristics and application fields.When choosing the processing method, it needs to be selected according to the specific product requirements and uses.

Your cold rolling and hot rolling supplier — Wanzhi

We have hot rolled steel strip, cold rolled steel coil, hot rolled steel sheet, cold rolled steel sheet, we provide for you

1.24-hour pre-sales and after-sales service

2.Free quote

3.Consistently deliver on time

4.Quality products, perfect service